LaFeSi-base magnetic refrigeration composite block body material based on grain boundary diffusion technique and preparation method of composite block body material

A technology of magnetic refrigeration material and grain boundary diffusion, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve problems such as restricting commercial applications, and achieve the mitigation of magnetic volume effect, thermal hysteresis, and magnetic hysteresis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

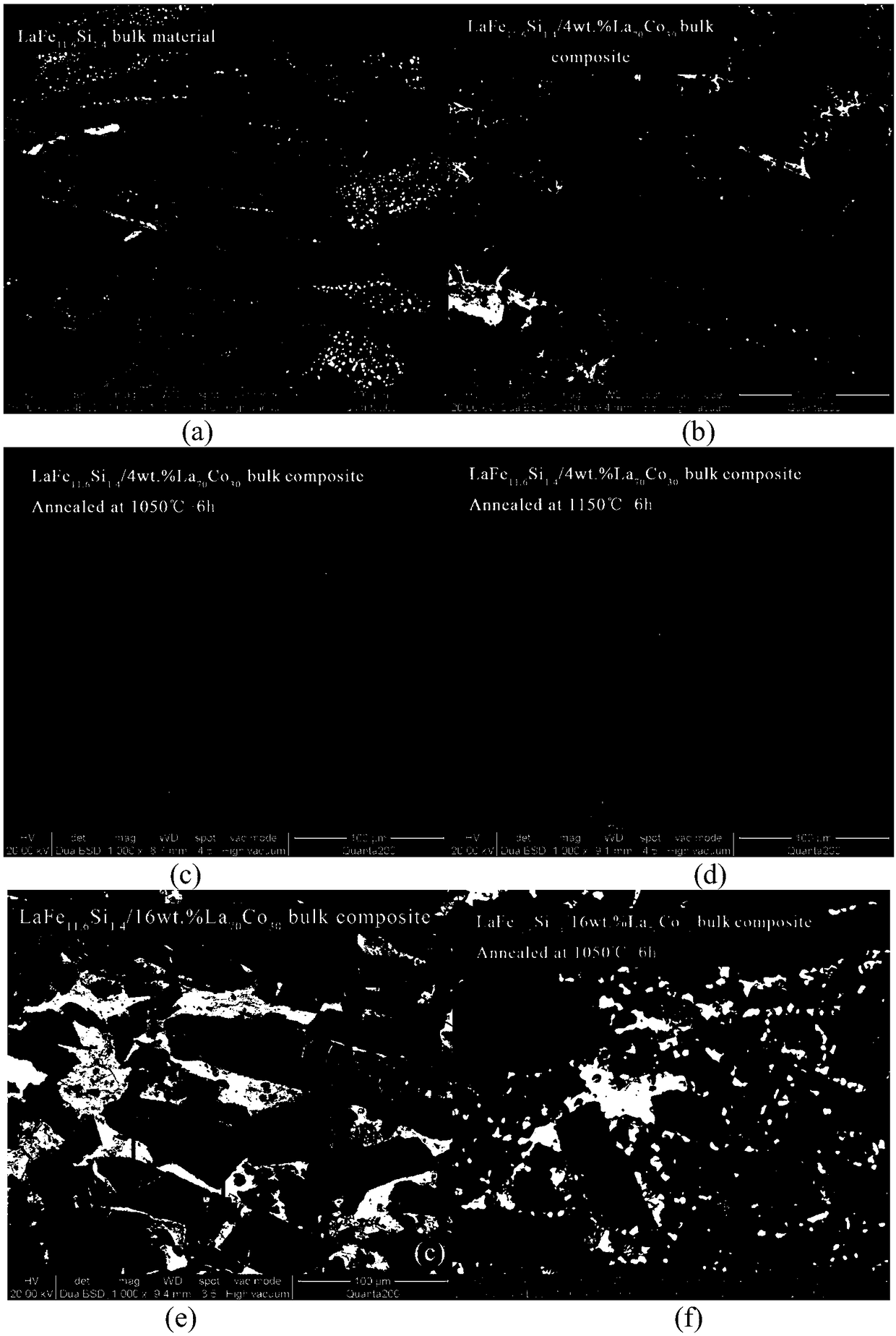

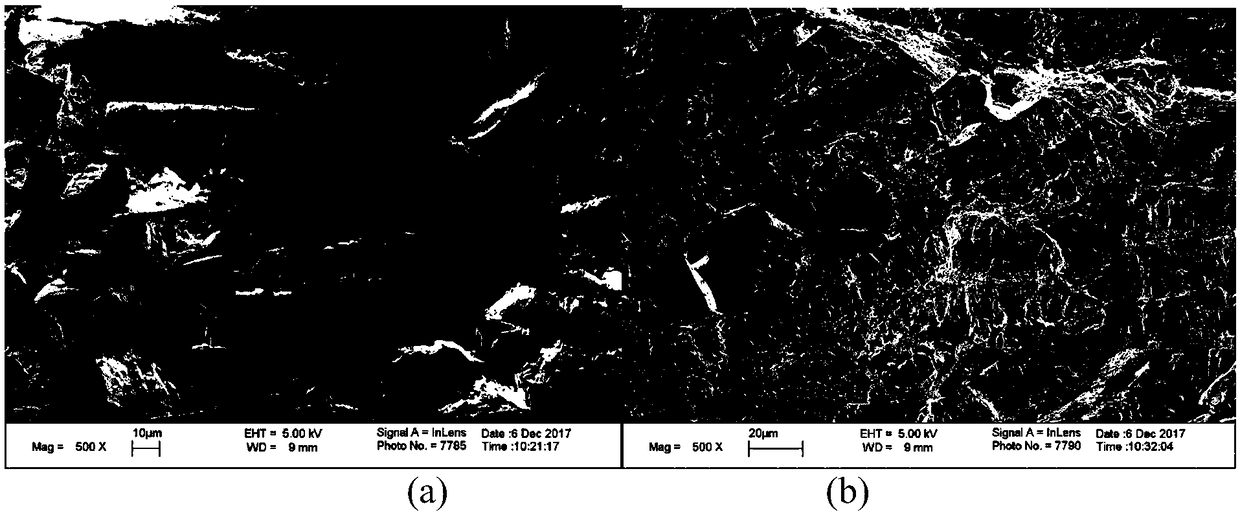

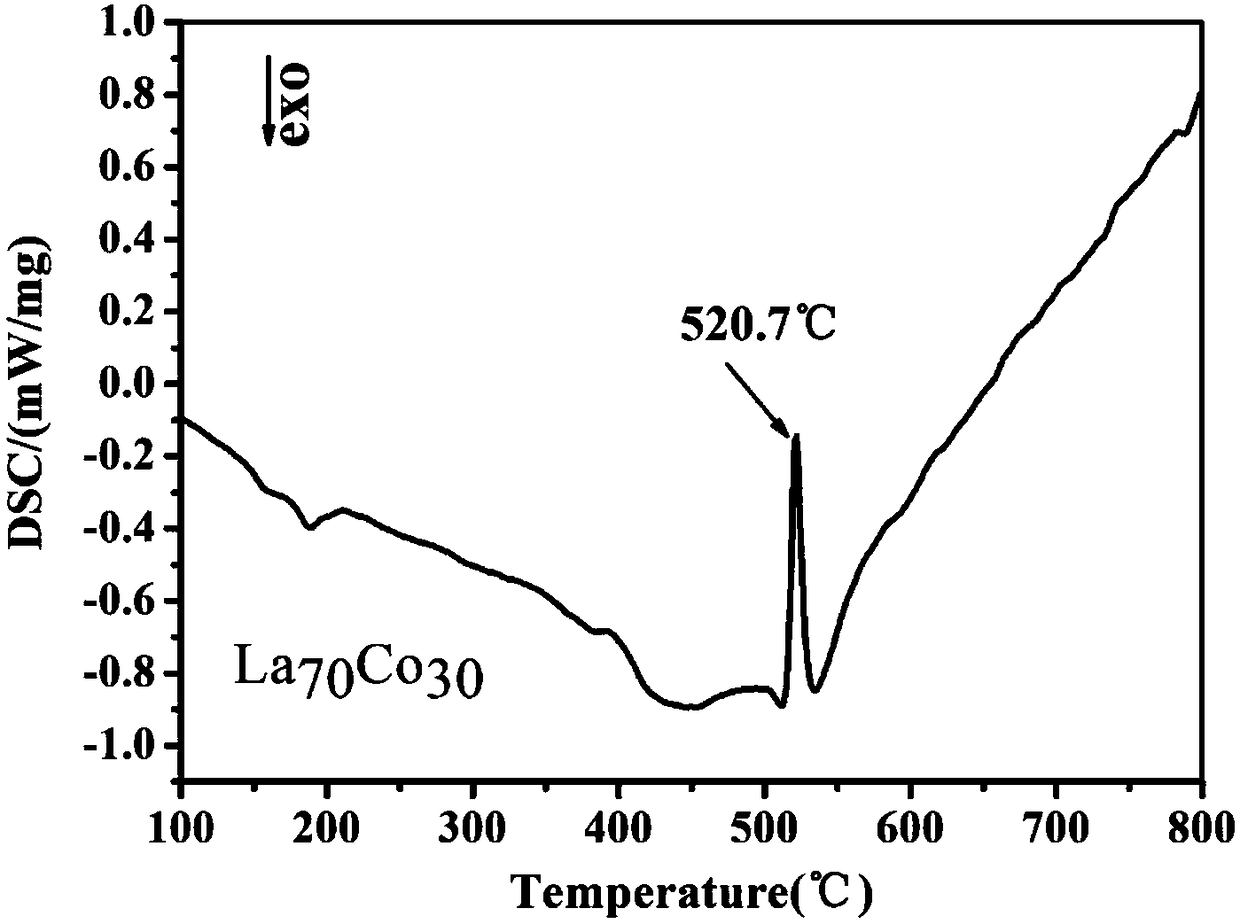

[0038] A kind of LaFeSi base magnetic refrigeration composite material, its preparation method is as follows:

[0039] Step 1: Press LaFe 11.6 Si 1.4 Alloy and La 70 co 30 Nominal composition of the alloy, raw materials are pure La (≥99.5wt.%), Fe (≥99.95wt.%), Co (≥99.95wt.%), Si (≥99.9999%) blocks, of which the La balance is 3wt .% to supplement the volatile mass loss during the smelting process, and the smelting was turned over 5 times to ensure the uniformity of the ingot. LaFe 11.6 Si 1.4 Alloy and La 70 co 30 The speeds of the alloy strips are 30m / s and 15m / s respectively. The resulting LaFe 11.6 Si 1.4 The alloy strip is sealed and annealed at 1100°C for 24 hours to obtain a 1:13 phase with a content of about 93.5wt.%, and the remainder is α-Fe. The obtained strips are mechanically ground and sieved to obtain LaFe with a particle size of 76-105um and less than 45um. 11.6 Si 1.4 Alloy particles and La with particle size less than 30um 70 co 30 alloy partic...

Embodiment 2

[0054] A kind of LaFeSi base magnetic refrigeration composite material, its preparation method is as follows:

[0055] Step 1: Press LaFe 11.6 Si 1.4 Alloy and La 70 co 30 Nominal composition of the alloy, the raw materials are pure La (≥99.5wt.%), Fe, Co (≥99.95wt.%), Si (≥99.9999%) blocks, and the La balance is 3wt.% to supplement the smelting process The loss of volatile mass, smelting and turning over 5 times to ensure the uniformity of the ingot. LaFe 11.6 Si 1.4 Alloy and La 70 co 30 The speeds of the alloy strips are 30m / s and 15m / s respectively. The resulting LaFe 11.6 Si 1.4 The alloy strip is sealed and annealed at 1100°C for 24 hours to obtain a 1:13 phase with a content of about 93.5wt.%, and the remainder is α-Fe. The obtained strips are mechanically ground and sieved to obtain LaFe with a particle size of 76-105um and less than 45um. 11.6 Si 1.4 Alloy particles and La with particle size less than 30um 70 co 30 alloy particles.

[0056] Step 2: Bas...

Embodiment 3

[0066] A kind of LaFeSi base magnetic refrigeration composite material, its preparation method is as follows:

[0067] Step 1: Press LaFe 11.6 Si 1.4 Alloy and La 70 co 30 Nominal composition of the alloy, the raw materials are pure La (≥99.5wt.%), Fe, Co (≥99.95wt.%), Si (≥99.9999%) blocks, and the La balance is 3wt.% to supplement the smelting process The loss of volatile mass, smelting and turning over 5 times to ensure the uniformity of the ingot. LaFe 11.6 Si 1.4 Alloy and La 70 co 30 The speeds of the alloy strips are 30m / s and 15m / s respectively. The resulting LaFe 11.6 Si 1.4 The alloy strip is sealed and annealed at 1100°C for 24 hours to obtain a 1:13 phase with a content of about 93.5wt.%, and the remainder is α-Fe. The obtained strips are mechanically ground and sieved to obtain LaFe with a particle size of 76-105um and less than 45um. 11.6 Si 1.4 Alloy particles and La with particle size less than 30um 70 co 30 alloy particles.

[0068] Step 2: Bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com