Manufacturing method of additional material for all-ceramic dental restoration

An oral restoration and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of material waste, additive manufacturing technology that cannot meet the production requirements of all-ceramic oral restorations, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1: The abutment to be restored is prepared, the occlusal surface is ground at least 1.5 mm, the lingual and buccal sides are ground 0.8-1.5 mm, and the axial convergence angle is 6-8 degrees.

[0044] Step 2, use silicone rubber to take a full-mouth impression, and pour it with plaster to obtain a model. After trimming the die, put it into the Shining 3D desktop 3D scanner DS200+ to generate a digital model of the dentition, and then use the ExoCad dental CAD software to design the oral restoration model.

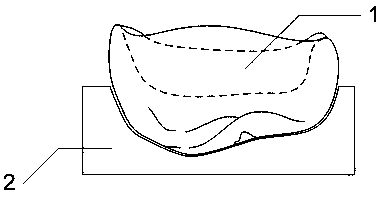

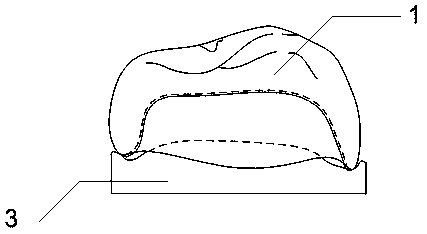

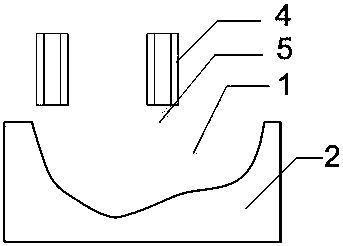

[0045] Step 3. Import the designed oral restoration model into the self-developed ToothFairy software, enlarge it according to the scale ratio of 1.265, and then design the digital models of convex and concave female models based on this as a template, and calculate the dental restoration 3D fill / pack path for volumes. like image 3 As shown, this path has been compensated for the nozzle thickness (approximately 0.1mm).

[0046] Step 4: Input the digital mode...

Embodiment 2

[0055] Step 1: The abutment to be restored is prepared, the occlusal surface is ground at least 1.5 mm, the lingual and buccal sides are ground 0.8-1.5 mm, and the axial convergence angle is 6-8 degrees.

[0056] Step 2: Use the Planmeca PlanScan intraoral scanner to directly scan the patient's mouth to generate a digital model of the dentition, and then use the ExoCad dental CAD software to design the oral restoration model.

[0057] Step 3. Import the designed oral restoration model into the self-developed ToothFairy software, enlarge it according to the scale ratio of 1.265, and then design the digital models of convex and concave female models based on this as a template, and calculate the dental restoration 3D fill / pack path for volumes. like image 3 As shown, this path has been compensated for the nozzle thickness (approximately 0.1mm).

[0058] Step 4: Input the digital models of the convex negative mold and the concave negative mold into the SLA light-curing 3D prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com