A honeycomb ceramic carrier with stable water absorption and preparation method thereof

A technology of honeycomb ceramic carrier and water absorption rate, applied in ceramic products, separation methods, clay preparation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the honeycomb ceramic carrier with stable water absorption rate in the present invention comprises the following steps:

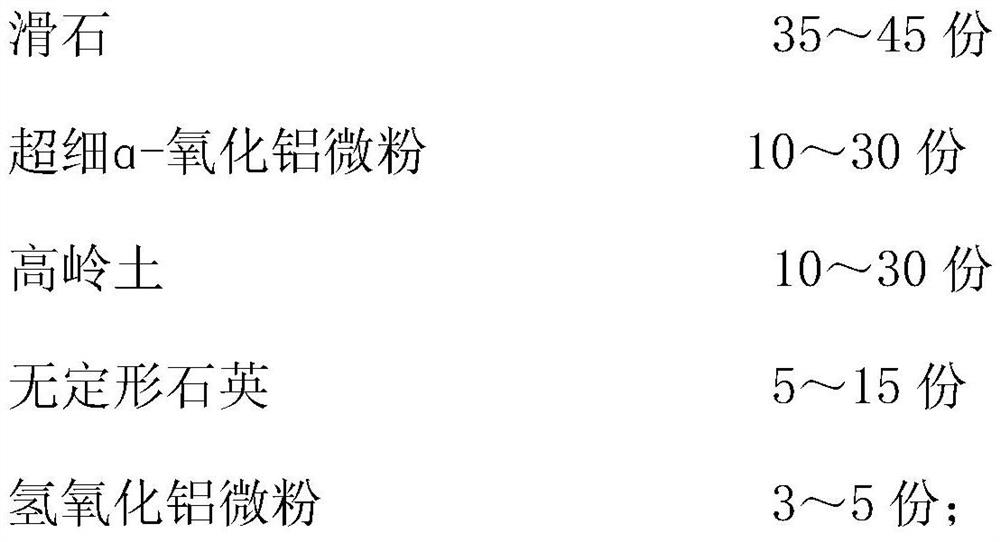

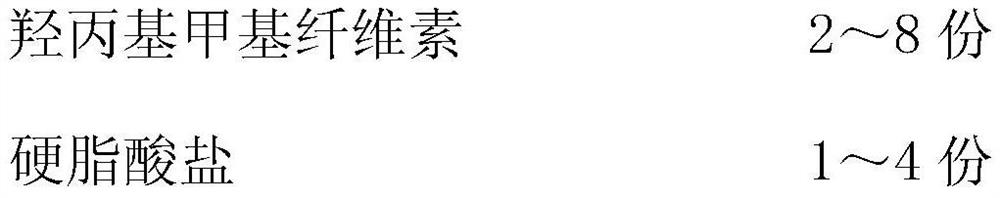

[0037] 1) 35 parts of talc, 10 parts of superfine α-alumina micropowder, 10 parts of kaolin, 5 parts of amorphous quartz, 3 parts of aluminum hydroxide micropowder, 2 parts of hydroxypropyl methylcellulose, 1 part of stearate , 2 parts of glycerin, 0.5 parts of lubricating oil, and 25 parts of pure water. The formula weighs each raw material, and then sieves the raw materials of talc, ultrafine α-alumina micropowder, kaolin, amorphous quartz and aluminum hydroxide micropowder, and then adds hydroxyl Propyl methylcellulose, stearate, the weight ratio of the precursor powder and the auxiliary agent is 85:10, mixed at high speed, the bulk density after mixing is 0.54g / cm 3 ;

[0038] 2) Continue to add glycerin, lubricating oil, and pure water to the mixture prepared in step 1), then knead, vacuum mud, the vacuum degree is 0.7...

Embodiment 12

[0056] A honeycomb ceramic carrier with stable water absorption and a preparation method thereof, which is composed of precursor powder and auxiliary agents. The ratio of powder and additives is shown in Table 4:

[0057]

[0058] 1) Take the bulk density as 0.42g / cm 3 , talc with particle size D50=12.2μm, bulk density is 0.72g / cm 3 , Ultrafine α-alumina micropowder with particle size D50=1.2μm, bulk density is 0.23g / cm 3 , flaky kaolin with particle size D50=2μm, bulk density is 0.42g / cm 3 , Amorphous quartz with a particle size of D50=3.7μm. The bulk density is 0.22g / cm 3 , aluminum hydroxide micropowder with a particle diameter of D50=1.2 μm, passing through a sieve with an aperture of 0.10 mm respectively, then adding stearate and hydroxypropyl methylcellulose, batching according to the ratio described in Table 1, and mixing at a high speed, Bulk density after mixing is 0.43g / cm 3 ;

[0059] 2) Add glycerin, lubricating oil, and pure water to the high-speed mixed ...

Embodiment 13

[0063] 1) Take the bulk density as 0.48g / cm 3 , talc with a particle size of D50 = 13.5μm, the bulk density is 0.78g / cm 3 , Ultrafine α-alumina micropowder with particle size D50=1.8μm, bulk density is 0.29g / cm 3 , flaky kaolin with particle size D50=3.5μm, bulk density is 0.45g / cm 3 , fused silica with a particle size of D50=4.2μm. The bulk density is 0.24g / cm 3 , the aluminum hydroxide micropowder of particle diameter D50=1.7 μ m, pass through the sieve cloth of 0.10mm respectively in aperture, add stearate, hydroxypropyl methylcellulose subsequently. Carry out batching by the ratio described in table 1, mix at high speed, Bulk density after mixing is 0.55g / cm 3 ,

[0064] 2) Add glycerin, lubricating oil, and pure water to the high-speed mixed powder for kneading, vacuum mud refining (vacuum degree 0.95 (due to the upper limit of the loose packing density of the carrier, the water absorption rate of the product will be too high, and the vacuum degree needs to be increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com