Method for synthesizing tire rubber reinforcing resin by using bio-oil as raw material

A technology of rubber reinforced resin and bio-oil is applied in the field of tire rubber reinforced resin to achieve the effect of improving reinforcement and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for synthesizing tire rubber reinforced resin with biological oil as raw material, the preparation steps are as follows:

[0026] Add 29.5 Kg of bio-oil, 117.5 Kg of phenol, and 2.3 Kg of 0.1mol / L oxalic acid solution into the reactor, raise the temperature to 100°C, add 60 Kg of formaldehyde solution with a concentration of 37%, and heat up to 100°C for 1 hour. Turn on vacuum dehydration, then add 50 Kg of cashew nut oil, and heat up to 160 ° C for 3 hours. Distill under reduced pressure for 20 minutes under the condition of vacuum degree of 0.08MPa, and then neutralize with 2.1Kg of 30% NaOH solution to obtain tire rubber reinforced resin. The resin has a softening point of 91.2°C and a free phenol content of 0.71%.

Embodiment 2

[0028] A method for synthesizing tire rubber reinforced resin with biological oil as raw material, the preparation steps are as follows:

[0029] Add 44 Kg of bio-oil, 103 Kg of phenol, and 2.7 Kg of p-toluenesulfonic acid into the reactor, raise the temperature to 90°C, and add 90 Kg of formaldehyde solution with a concentration of 37%, raise the temperature to 90°C for 1 hour, and then turn on vacuum dehydration. Then add 54 Kg of cashew nut oil and heat up to 180°C for 1.5 hours. Under the condition of vacuum degree of 0.09MPa, vacuum distillation was carried out for 20min, and then neutralized with 2.5Kg of triethanolamine solution to obtain tire rubber reinforced resin. The resin has a softening point of 95.8°C and a free phenol content of 0.04%.

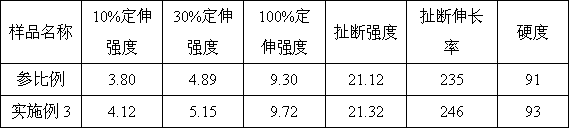

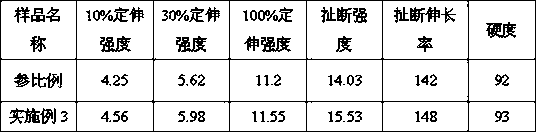

Embodiment 3

[0031] A method for synthesizing tire rubber reinforced resin with biological oil as raw material, the preparation steps are as follows:

[0032] Add 22.05Kg of bio-oil, 125 Kg of phenol, and 3.4 Kg of 0.1mol / L hydrochloric acid into the reactor, raise the temperature to 95°C, and add 63 Kg of formaldehyde solution with a concentration of 37%, raise the temperature to 95°C for 1 hour, and then turn on vacuum dehydration . Add 35 Kg cashew nut oil again, heat up to 180 ℃ and react for 1.5 hours. Under the condition of vacuum degree of 0.07MPa, vacuum distillation is carried out for 15min, and then neutralized with 0.9Kg of 30% NaOH solution to obtain tire rubber reinforced resin. The resin has a softening point of 101°C and a free phenol content of 0.091%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com