Paying-off wheel and rubber-coating material and preparation method of rubber-coating material

A pay-off reel and rubber coating technology, which is applied in the material and preparation field of pay-off reel rubber, can solve the problems affecting the normal use of the pay-off reel, heat generated by wire friction, and the hardness of the rubber coating, etc., to achieve excellent weather resistance Good aging performance, elasticity and wear resistance, and high compression modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

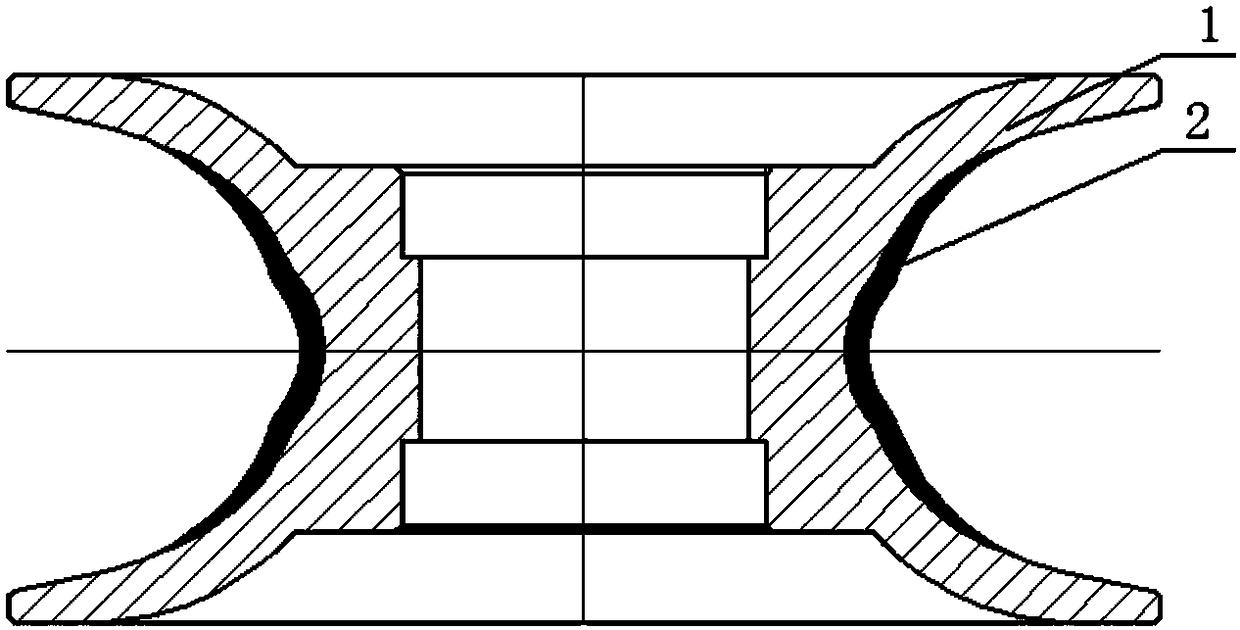

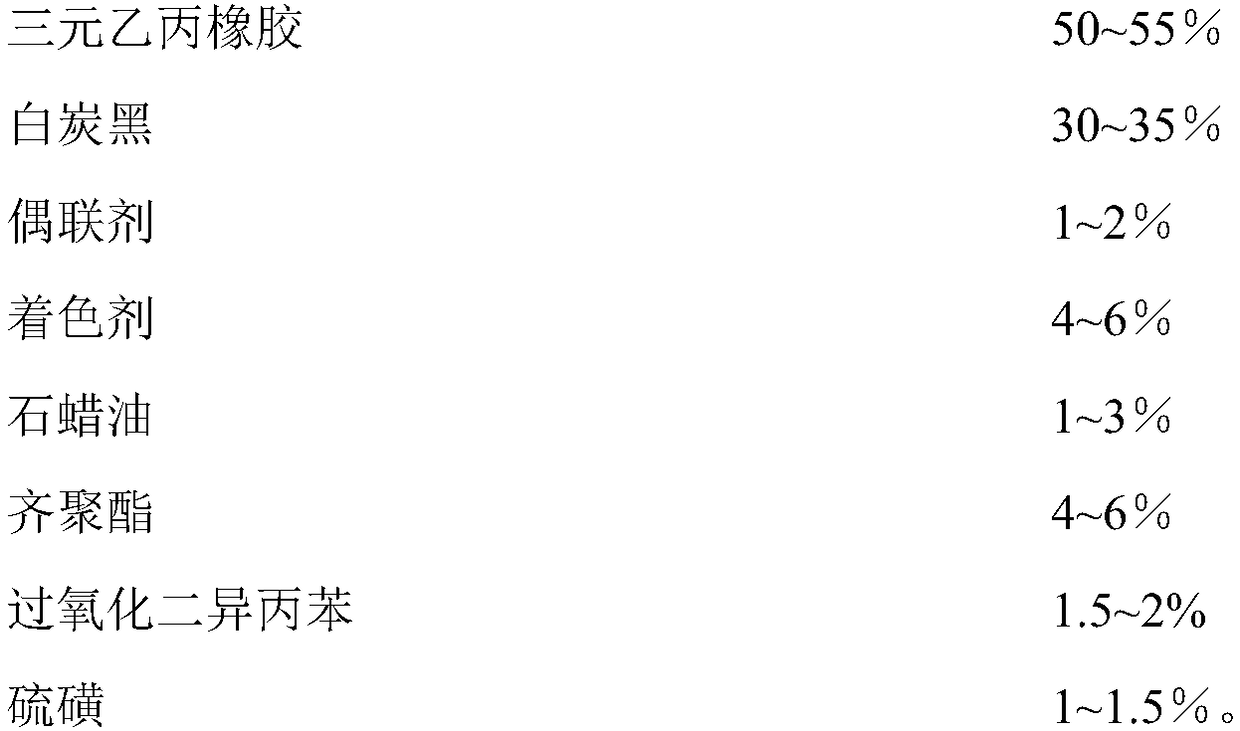

[0037] like figure 1 As shown, a pay-off wheel of this embodiment includes a pay-off wheel body 1, and the surface of the wheel groove of the pay-off wheel body 1 is provided with a coating layer 2, wherein the material of the pay-off wheel can be aluminum and its alloy, or It can be MC nylon, and the wire placed can be an overhead aluminum core wire, or a cable or optical cable. The material components and weight percentages of the above-mentioned encapsulation layer 2 are shown in Table 1.

[0038] Table 1 Material components and percentage content of encapsulation in Example 1

[0039] Raw material name

Percentage %

50

Silica

35

coupling agent

2

Colorant

4

Paraffin oil

2.5

Oligopolyester

4

1.5

1

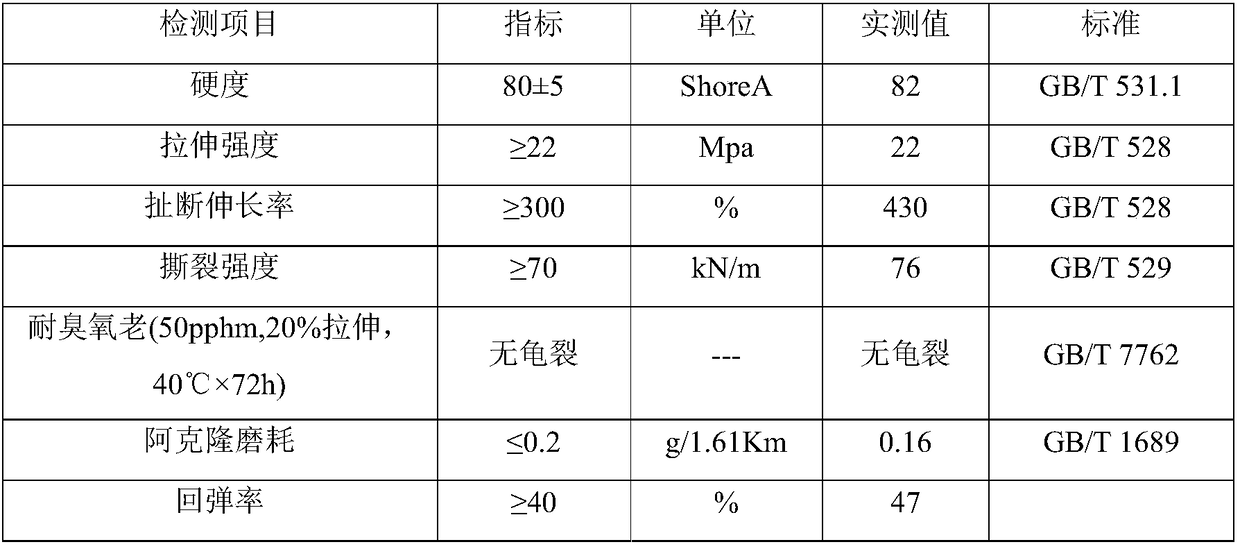

[0040] In this example, the white carbon black is HD200MP produced by Wuxi Quecheng Silicon Chemical Co., Ltd. The main performance parameters ar...

Embodiment 2

[0058] Table 2 shows the components and weight percentages of a pay-off wheel rubber coating material in this embodiment.

[0059] The material components and percentage content of table 2 embodiment 2 encapsulation

[0060] Raw material name

Percentage %

52

Silica

32

coupling agent

1.5

Colorant

4.5

Paraffin oil

2

Oligopolyester

5

2

1

[0061] In this example, the white carbon black is HD200MP produced by Wuxi Quecheng Silicon Chemical Co., Ltd. The main performance parameters are: the nitrogen adsorption specific surface area is 200-230m 2 / g, DBP absorption value is 200cm 3 / 100g. The coupling agent is silane coupling agent KH845-4 produced by Nanjing Shuguang Chemical Group Co., Ltd., and its chemical composition is bis-[Y-(triethoxysilyl)propyl]-tetrasulfide. EPDM rubber is J-4045 produced by the organic synthesis plant of Jilin Chemical ...

Embodiment 3

[0075] Table 3 shows the components and weight percentages of a pay-off reel encapsulating material in this embodiment.

[0076] The material components and percentage content of table 3 embodiment 3 encapsulation

[0077] Raw material name

Percentage %

EPDM rubber

54

Silica

30

coupling agent

1

Colorant

5

Paraffin oil

1

Oligopolyester

5.5

2

sulfur

1.5

[0078] In this example, the white carbon black is HD200MP produced by Wuxi Quecheng Silicon Chemical Co., Ltd. The main performance parameters are: the nitrogen adsorption specific surface area is 200-230m 2 / g, DBP absorption value is 300cm 3 / 100g. The coupling agent is silane coupling agent KH845-4 produced by Nanjing Shuguang Chemical Group Co., Ltd., and its chemical composition is bis-[Y-(triethoxysilyl)propyl]-tetrasulfide. EPDM rubber is J-4045 produced by the organic synthesis plant of Jilin Chemical In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nitrogen adsorption specific surface area | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com