Environmental protection PVC color cake

A PVC resin powder and environmental protection technology, applied in the field of polyvinyl chloride environmental protection materials, can solve the problems of difficult to control color difference, easy to produce color change, permanent yellow not resistant to high temperature, etc., and achieve low manufacturing cost, good safety and economy. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

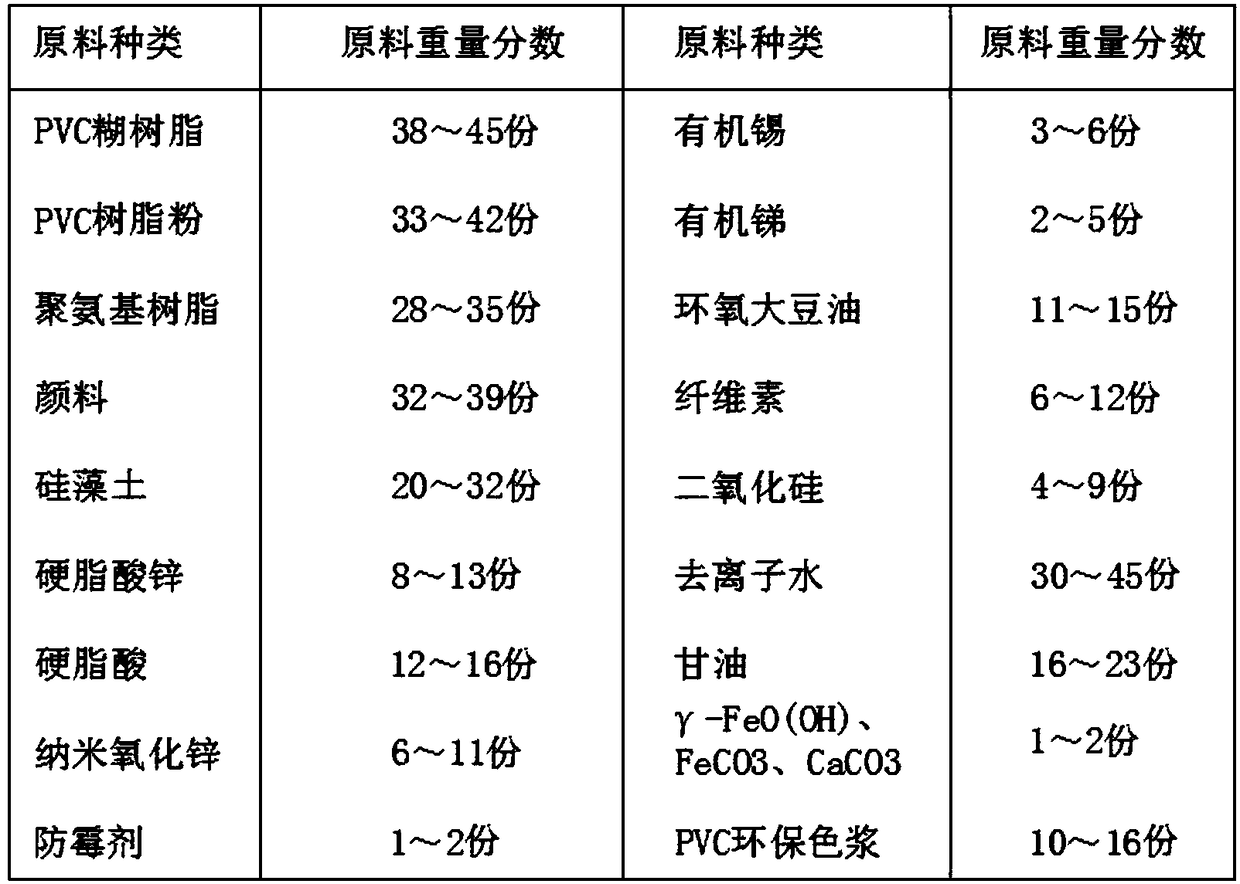

[0022] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly PVC color cake, which includes the following raw materials: 45 parts of PVC paste resin, 42 parts of PVC resin powder, 35 parts of polyurethane resin, and 39 parts of pigment , 32 parts of diatomaceous earth, 13 parts of zinc stearate, 16 parts of stearic acid, 11 parts of nano-zinc oxide, 6 parts of organic tin, 5 parts of organic antimony, 15 parts of epoxy soybean oil, 12 parts of cellulose, dioxide 9 parts of silicon, 45 parts of deionized water and 23 parts of glycerin.

[0023] Wherein, 2 parts of γ-FeO(OH), FeCO 3 and CaTiO 3 A mixture of which, γ-FeO(OH), FeCO 3 and CaTiO 3 The addition ratio is 3:2:3.

[0024] Wherein, 2 parts of anti-mold agents are also added to the environmentally friendly PVC color cake.

[0025] Wherein, 16 parts of PVC environment-friendly color paste are also added in the environment-friendly PVC color cake.

[0026] Wher...

Embodiment 2

[0029] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly PVC color cake, which includes the following raw materials: 38 parts of PVC paste resin, 33 parts of PVC resin powder, 28 parts of polyurethane resin, and 32 parts of pigment , 20 parts of diatomite, 8 parts of zinc stearate, 12 parts of stearic acid, 6 parts of nano-zinc oxide, 3 parts of organic tin, 2 parts of organic antimony, 11 parts of epoxy soybean oil, 6 parts of cellulose, dioxide 4 parts of silicon, 30 parts of deionized water and 16 parts of glycerin.

[0030] Wherein, 1 part of γ-FeO(OH), FeCO 3 and CaTiO 3 A mixture of which, γ-FeO(OH), FeCO 3 and CaTiO 3 The addition ratio is 2:1:1.

[0031] Wherein, 1 part of antifungal agent is also added to the environmentally friendly PVC color cake.

[0032] Wherein, 10 parts of PVC environment-friendly color paste are also added to the environment-friendly PVC color cake.

[0033] Wherein, the color ...

Embodiment 3

[0036] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly PVC color cake, which includes the following raw materials: 45 parts of PVC paste resin, 33 parts of PVC resin powder, 35 parts of polyurethane resin, and 32 parts of pigment , 32 parts of diatomite, 8 parts of zinc stearate, 16 parts of stearic acid, 6 parts of nano-zinc oxide, 6 parts of organic tin, 2 parts of organic antimony, 15 parts of epoxy soybean oil, 6 parts of cellulose, dioxide 9 parts of silicon, 30 parts of deionized water and 23 parts of glycerin.

[0037] Wherein, 1 part of γ-FeO(OH), FeCO 3 and CaTiO 3 A mixture of which, γ-FeO(OH), FeCO 3 and CaTiO 3 The addition ratio is 3:1:3.

[0038] Wherein, 1 part of antifungal agent is also added to the environmentally friendly PVC color cake.

[0039] Wherein, 16 parts of PVC environment-friendly color paste are also added in the environment-friendly PVC color cake.

[0040] Wherein, the color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com