Polyphenylene sulfide resin composition with low dielectric constant and used for NMT (Nano Molding Technology) and preparation method

A technology of polyphenylene sulfide resin and low dielectric constant, applied in the field of engineering plastics, can solve the problems of high dielectric constant, unable to meet the long wavelength, high frequency and large capacity of 5G communication, and achieve high reaction rate and heat resistance Excellent performance and moldability, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

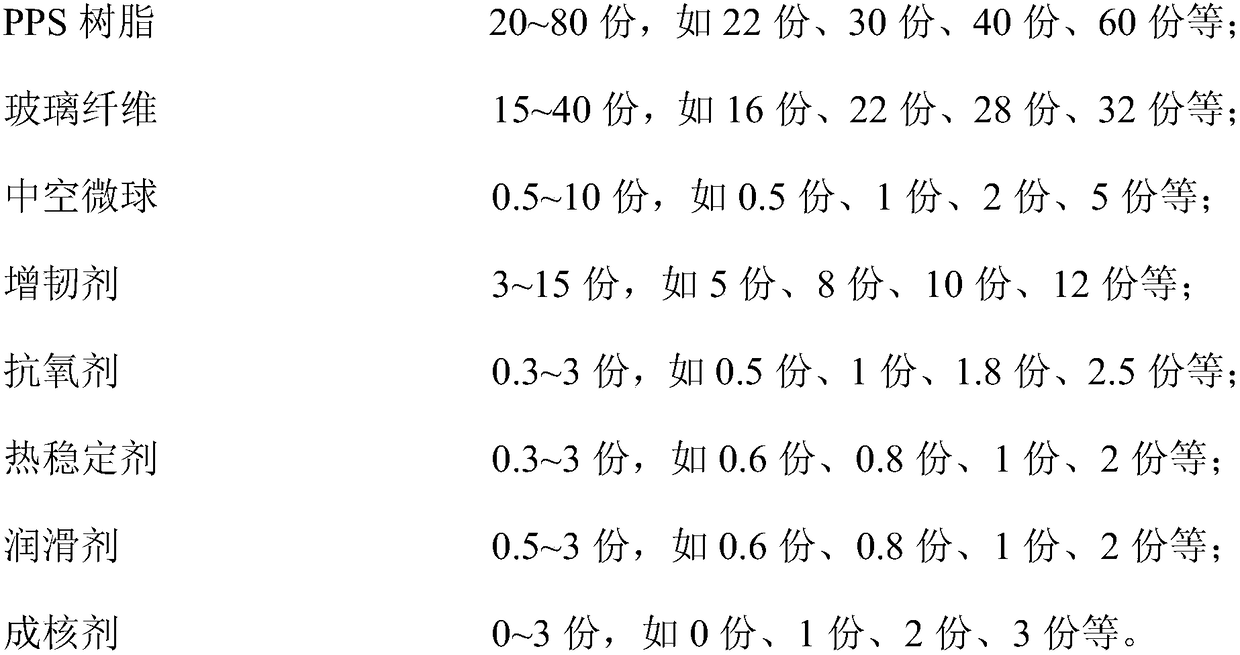

[0060] Embodiment 1: The polyphenylene sulfide resin composition of this embodiment includes the following components in parts by mass:

[0061]

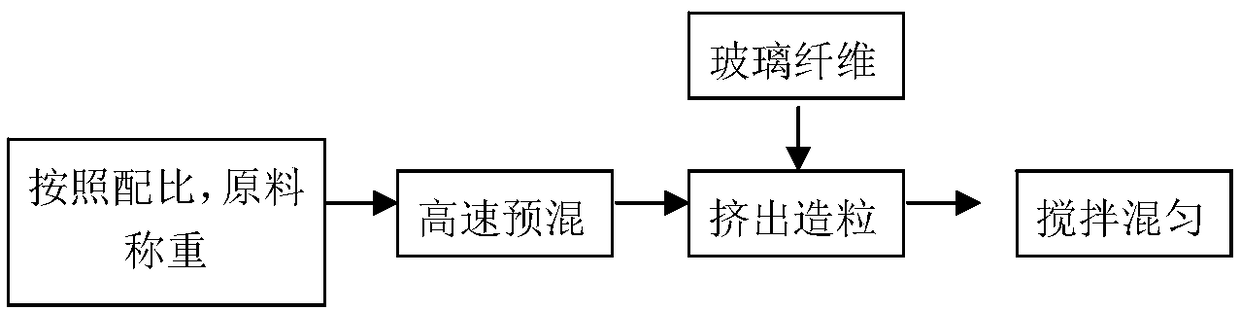

[0062] The preparation method of the polyphenylene sulfide resin composition in the present embodiment is as follows:

[0063] According to the proportion, mix the above-mentioned PPS resin, hollow microspheres, toughening agent, antioxidant, heat stabilizer and lubricant to obtain a mixture;

[0064] Add glass fiber to the mixture, put it into an extruder, carry out melt extrusion and granulation, stir evenly, and obtain a polyphenylene sulfide resin composition.

[0065] The heating temperature of the extruder is set as follows: Zone 1 160-200 °C, Zone 2 220-250 °C, Zone 3 230-270 °C, Zone 4 250-290 °C, Zone 5 270-310 °C, Zone 6 280-320 °C And machine head 260 ~ 280 ℃.

Embodiment 2

[0066] Embodiment 2: The polyphenylene sulfide resin composition of this embodiment includes the following components in parts by mass:

[0067]

[0068] The preparation method of the polyphenylene sulfide resin composition of this example is the same as that of Example 1.

Embodiment 3

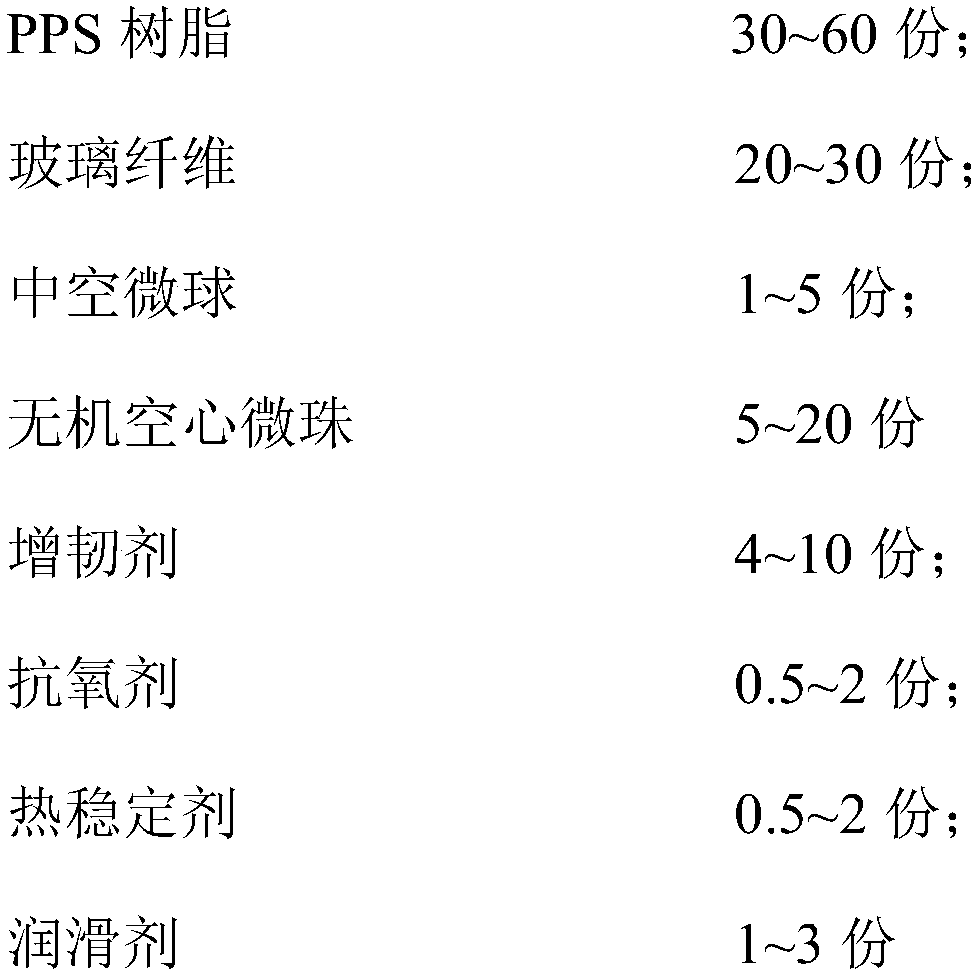

[0069] Embodiment 3: The polyphenylene sulfide resin composition of this embodiment includes the following components in parts by mass:

[0070]

[0071]

[0072] Among them, the glass fiber is a low dielectric constant chopped glass fiber, the hollow microsphere is a polymer microsphere, the inorganic hollow microsphere is a hollow glass microsphere, and the toughening agent is glycidyl methacrylate copolymer and styrene / butylene Diene / styrene block copolymer, the nucleating agent is long-chain fatty acid calcium.

[0073] The preparation method of the nano-injection-molded polyphenylene sulfide resin composition in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com