Preparation method of thenoyltrifluoroacetone (HTTA) modified rare earth hydroxide nano-sheet fluorescence reinforcing material

A technology of rare earth hydroxide and fluorescence enhancement, which is applied in the direction of luminescent materials, chemical instruments and methods, nanotechnology, etc., can solve the problems of reducing, losing the ultra-thin two-dimensional characteristics of nanosheets, and increasing the thickness, so as to achieve enhanced fluorescence performance, Effect of reducing fluorescence quenching phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

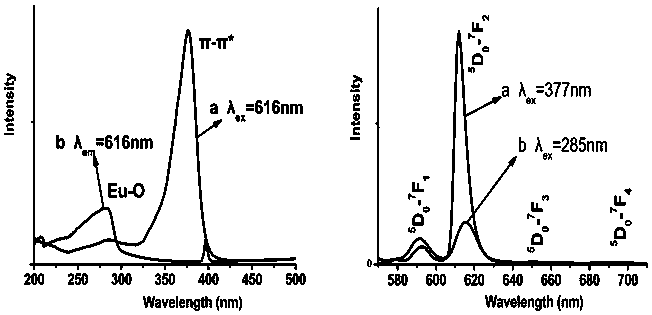

Image

Examples

Embodiment 1

[0019] a. Get 1.0393g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O) was dissolved in 100ml deionized water, then added 0.0637g europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O), make it mix uniformly;

[0020] b. Stir magnetically at room temperature, and add dilute ammonia water drop by drop to the mixed solution in step a, adjust the pH of the solution to 7.2-7.5, and if it becomes turbid, continue stirring for 30 minutes to make it evenly mixed;

[0021] c. the mixed solution obtained in step b is placed in a microwave field, under N 2 Continue to microwave for 20min in a protective atmosphere (microwave frequency 2.45GHz);

[0022] d. Suction filter, wash with water and ethanol the sample after microwave in step c, then dry and grind in a vacuum oven at 35°C to obtain dry powdered rare earth hydroxide hydrate Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O;

[0023] e. Take Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O sample 0.5g, N 2 Under the condition of continuous micr...

Embodiment 2

[0027] a. Get 1.5038g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O) was dissolved in 110ml deionized water, then added 0.0922g europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O), make it mix uniformly;

[0028] b. Stir magnetically at room temperature, and add dilute ammonia water drop by drop to the mixed solution in step a, adjust the pH of the solution to about 7.5, and if it becomes turbid, continue stirring for 30 minutes to make it evenly mixed;

[0029] c. the mixed solution obtained in step b is placed in a microwave field, under N 2 Continue to microwave for 20min in a protective atmosphere (microwave frequency 2.45GHz);

[0030] d. Suction filter, wash with water and ethanol the sample after microwave in step c, then dry and grind in a vacuum oven at 40°C to obtain dry powdered rare earth hydroxide hydrate Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O;

[0031] e. Take Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O sample 0.5g, N 2 Ion exchange was carried out in a satu...

Embodiment 3

[0035] a. Get 1.0379g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O) was dissolved in 120ml deionized water, then added 0.0636g europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O), make it mix uniformly;

[0036] b. Stir magnetically at room temperature, and add dilute ammonia water dropwise to the mixed solution in step a, adjust the pH of the solution to 7.6, and if it becomes turbid, continue stirring for 30 minutes to make it evenly mixed;

[0037] c. the mixed solution obtained in step b is placed in a microwave field, under N 2 Continue to microwave for 20min in a protective atmosphere (microwave frequency 2.45GHz);

[0038] d. Suction filter, wash with water and ethanol the sample after microwave in step c, then dry and grind in a vacuum oven at 35°C to obtain dry powdered rare earth hydroxide hydrate Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O;

[0039] e. Take Y 1.9 Eu 0.1 (OH) 5 NO 3 1.5H 2 O sample 0.5g, N 2 Ion exchange was carried out in a saturated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com