Preparation of phthalocyanine lanthanum-modified graphene composite extreme pressure antiwear agent and lubricating grease with antiwear agent

An extreme pressure anti-wear agent, graphene technology, applied in lubricating compositions, additives, petroleum industry and other directions, can solve the problem that lubricating grease is difficult to meet the requirements of construction machinery, and achieve good extreme pressure and anti-wear performance, low friction coefficient , The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 (graphene composite extreme pressure antiwear agent modified by lanthanum cyanine)

[0016] The invention provides a preparation method of a graphene composite extreme pressure antiwear agent modified by lanthanum phthalocyanine, which specifically comprises the following steps: firstly, the preparation of carboxylated graphene oxide, taking 100 milliliters of 1 mg / ml graphene oxide and uniformly dispersing Add 6.66ml of hydrobromic acid, stir vigorously at room temperature for 12 hours, then add 2g of oxalic acid, continue the reaction for 4 hours, wash with deionized water until neutral, and then use DMF to make 1mg / ml carboxylation oxidation Graphene dispersion, continuous ultrasonic dispersion for 24 hours; then prepare the graphene composite modified by lanthanum phthalocyanine, get 20 milliliters of the DMF homogeneous dispersion of 1mg / ml carboxylated graphene oxide prepared above, 70mg tetraaminolanthanum phthalocyanine, 0.0366 g of EDC, 0.0233 g of...

Embodiment 2

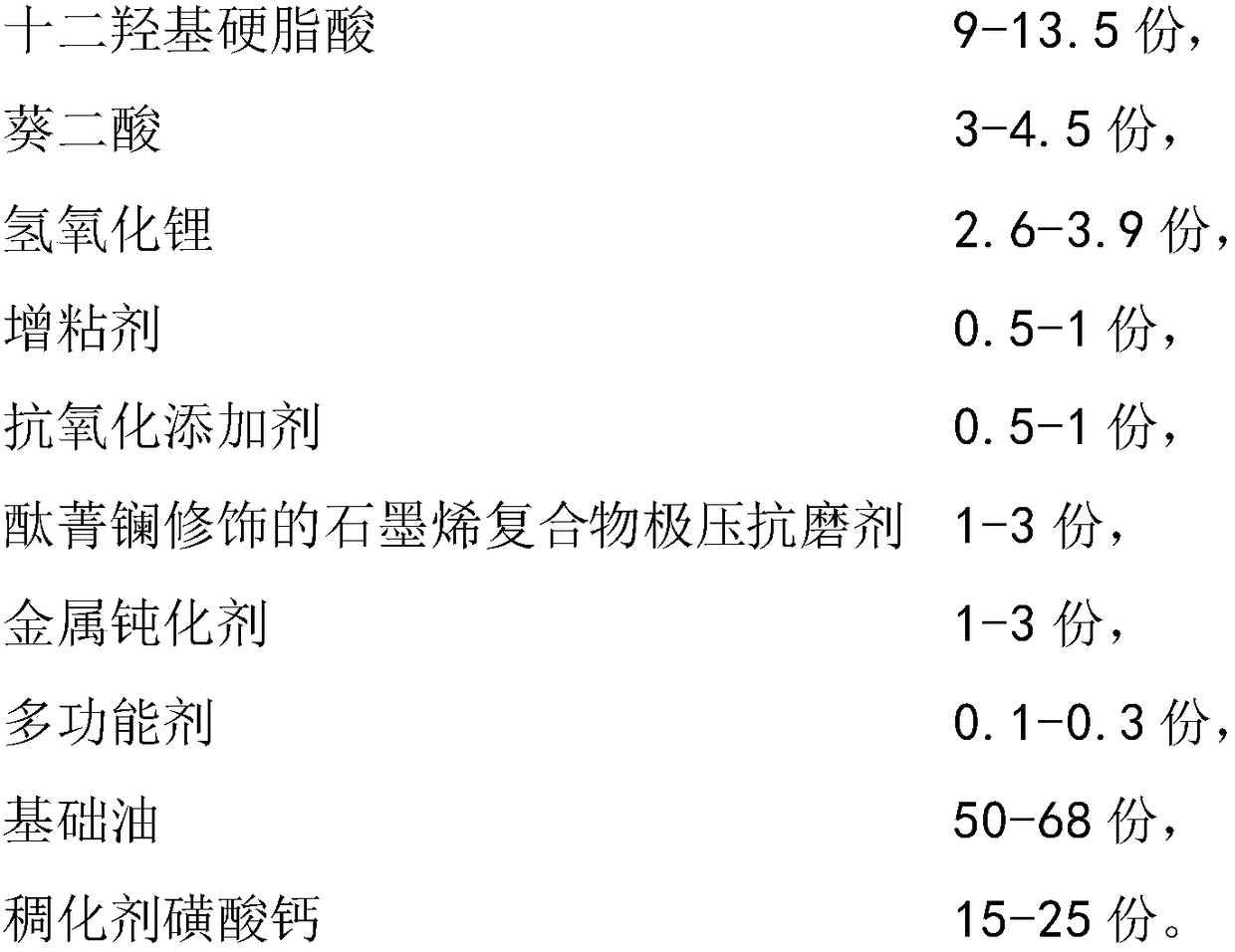

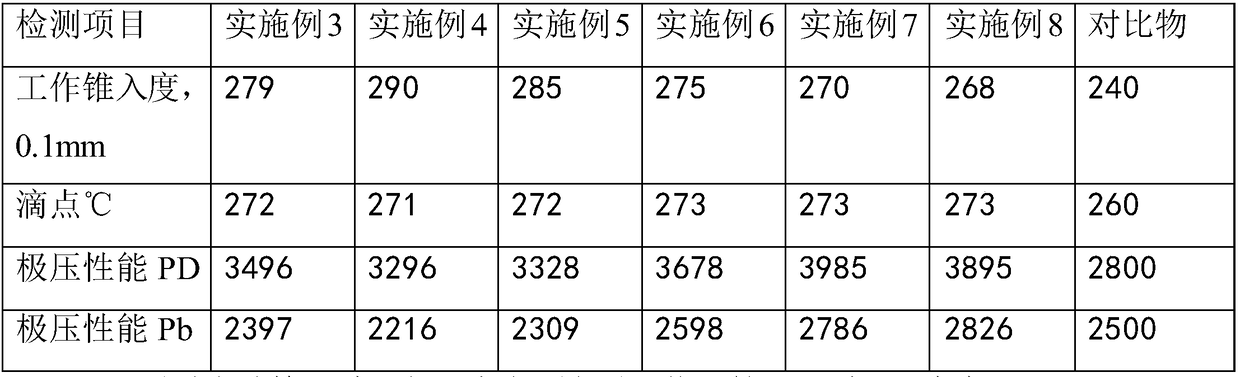

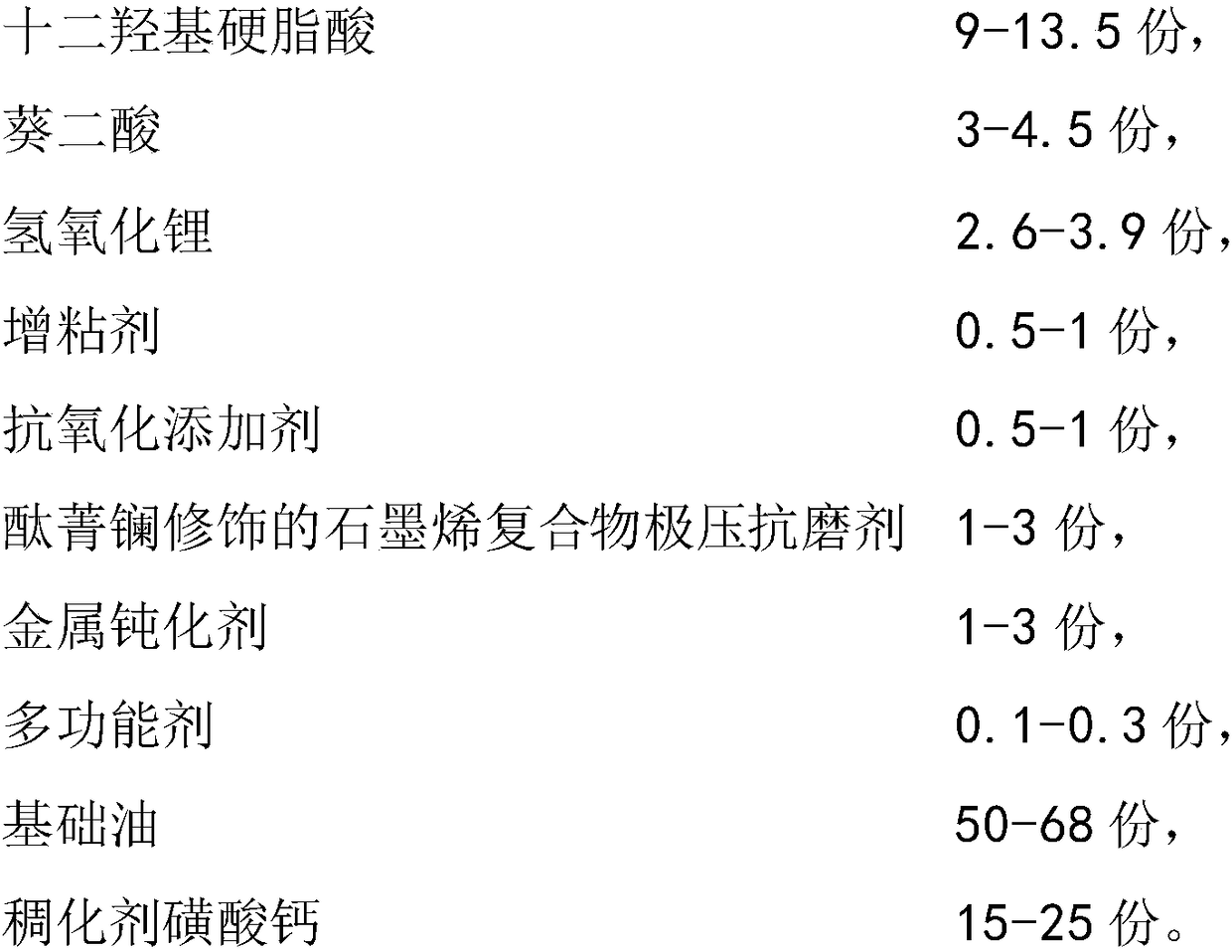

[0018] The present invention utilizes the lanthanum phthalocyanine modified graphene composite extrusion antiwear agent prepared in Example 1 to provide a grease containing the antiwear agent, specifically including 9-13.5 parts of lauryl hydroxystearic acid, 3 -4.5 parts of sebacic acid, 2.6-3.9 parts of lithium hydroxide, 0.5-1 part of tackifier, 0.5-1 part of antioxidant additive, 1-3 parts of graphene composite pole modified by lanthanum phthalocyanine Pressure and anti-wear agent, 1-3 parts of metal deactivator, 0.1-0.3 parts of multifunctional agent, 50-68 parts of base oil, 15-25 parts of thickener calcium sulfonate, using the above ingredients, first Add base oil into the reaction kettle, then add lauryl hydroxystearic acid, sebacic acid, and lithium hydroxide into the reaction kettle in sequence to heat and stir, stir for 2-3 hours, and the heating temperature is 60-80°C; then Add the mixed liquid heated and stirred by the reaction kettle to the quenching mixer for co...

Embodiment 3

[0020] 11.4 parts of lauryl hydroxystearic acid, 4 parts of sebacic acid, 3 parts of lithium hydroxide, 0.8 parts of tackifier, 0.6 parts of antioxidant additive, 2 parts of extreme pressure and antiwear agent of graphene composite modified by lanthanum phthalocyanine, 1.2 parts of metal deactivator, 0.2 parts of multifunctional agent, 57.3 parts of base oil, 20 parts of thickener calcium sulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com