Preparation and transformation method of streptococcus thermophilus competent cells

A technology of competent cells and Streptococcus thermophilus, applied in the biological field, can solve the problems of low transformation efficiency and achieve remarkable technological progress, high transformation efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Example 1: Establishment of Competent Preparation Method for Streptococcus thermophilus AR479

[0040] According to the research on the electrotransformation method of lactic acid bacteria reported in the literature, the following five commonly used competent preparation methods were first tried:

[0041] Method 1: Streak activation of glycerol-preserved strain AR479 at -80°C, culture LM17 overnight, inoculate 1% inoculum into LM17 containing threonine (100mM), culture at 37°C until OD 600 0.6-0.8, centrifuge at 5000x g at 4°C for 10 minutes. Wash twice with washing buffer (0.5M sucrose, 10% glycerol), then resuspend with resuspension buffer (10% glycerol and 30% PGE2000 solution), 100 μL per tube, store at -80°C, and use electrotransformation for later use.

[0042] Method 2: LM17 liquid culture overnight, inoculate LM17 containing lysozyme (10 mg / mL) with 1% inoculum, and culture to OD at 37°C 600 0.6-0.8, centrifuge at 5000x g at 4°C for 10 minutes. Wash twice wi...

Embodiment 2

[0054] Example 2: Optimization of Electrotransformation Conditions for Streptococcus thermophilus AR479

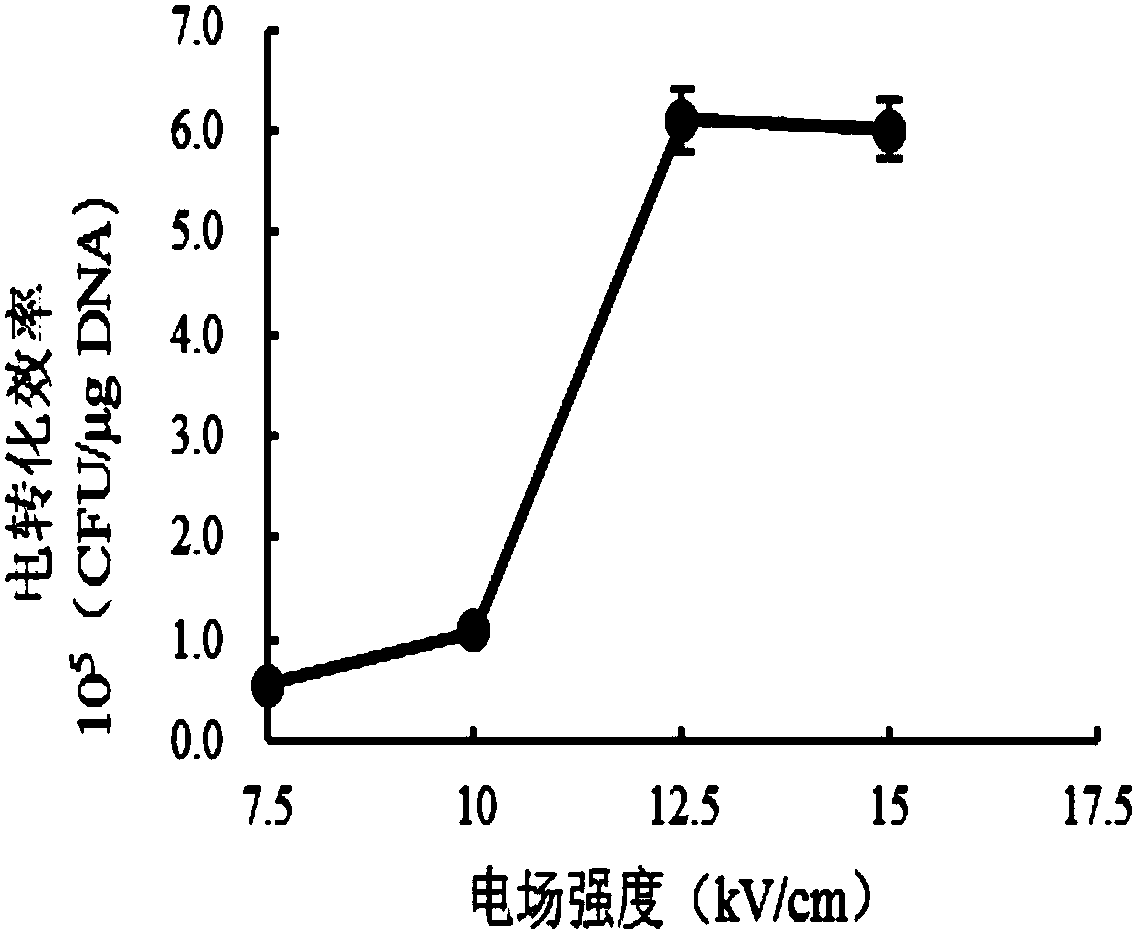

[0055] In the electroconversion process, the electric field strength is a key factor. Electroporation is the use of instantaneous high-voltage electric shock to the cell membrane to form holes so that DNA molecules can enter the cell. During the electric shock process, the voltage is too low or too high to make foreign DNA molecules enter the cells effectively. However, within a certain range of electric field strength, the stronger the electric field strength, the more holes will be produced on the cell membrane, the better the permeability, and the easier it is for foreign DNA molecules to enter the cell. The electroconversion efficiency of AR479 increases with the increase of electric field intensity ( figure 2 ), when the electric field strength reaches 12.5kV / cm, the electric conversion efficiency reaches the highest, which is 6×10 5 CFU / μg DNA. With the further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com