Silicon-germanium heterojunction bipolar transistor and manufacturing method

A heterojunction bipolar transistor technology, applied in the manufacture of germanium-silicon heterojunction bipolar transistors, the field of germanium-silicon heterojunction bipolar transistors, can solve the problem of increasing the capacitance of the collector area, increasing the size, and unfavorable Ft Increase and other problems, to achieve the effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

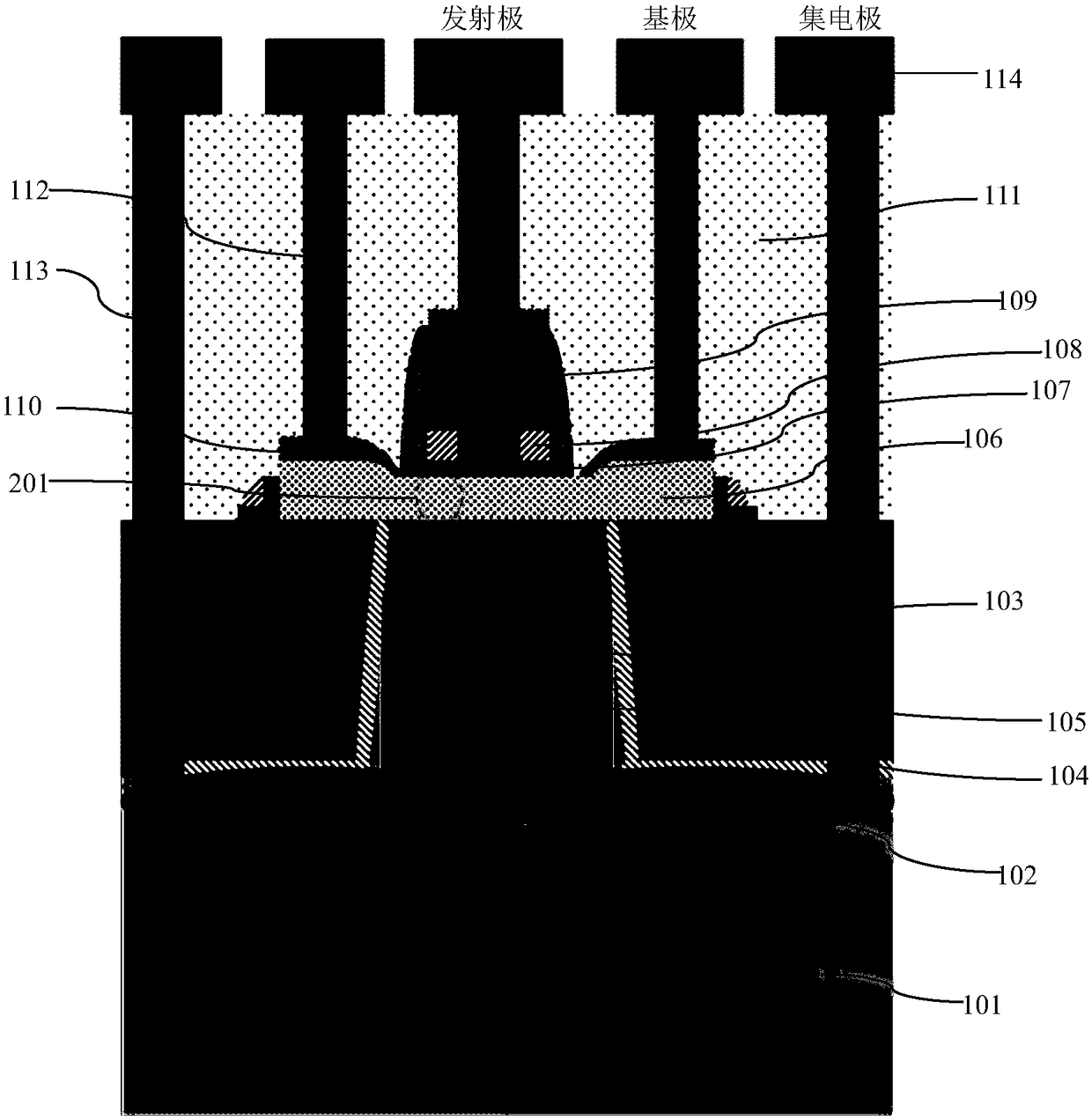

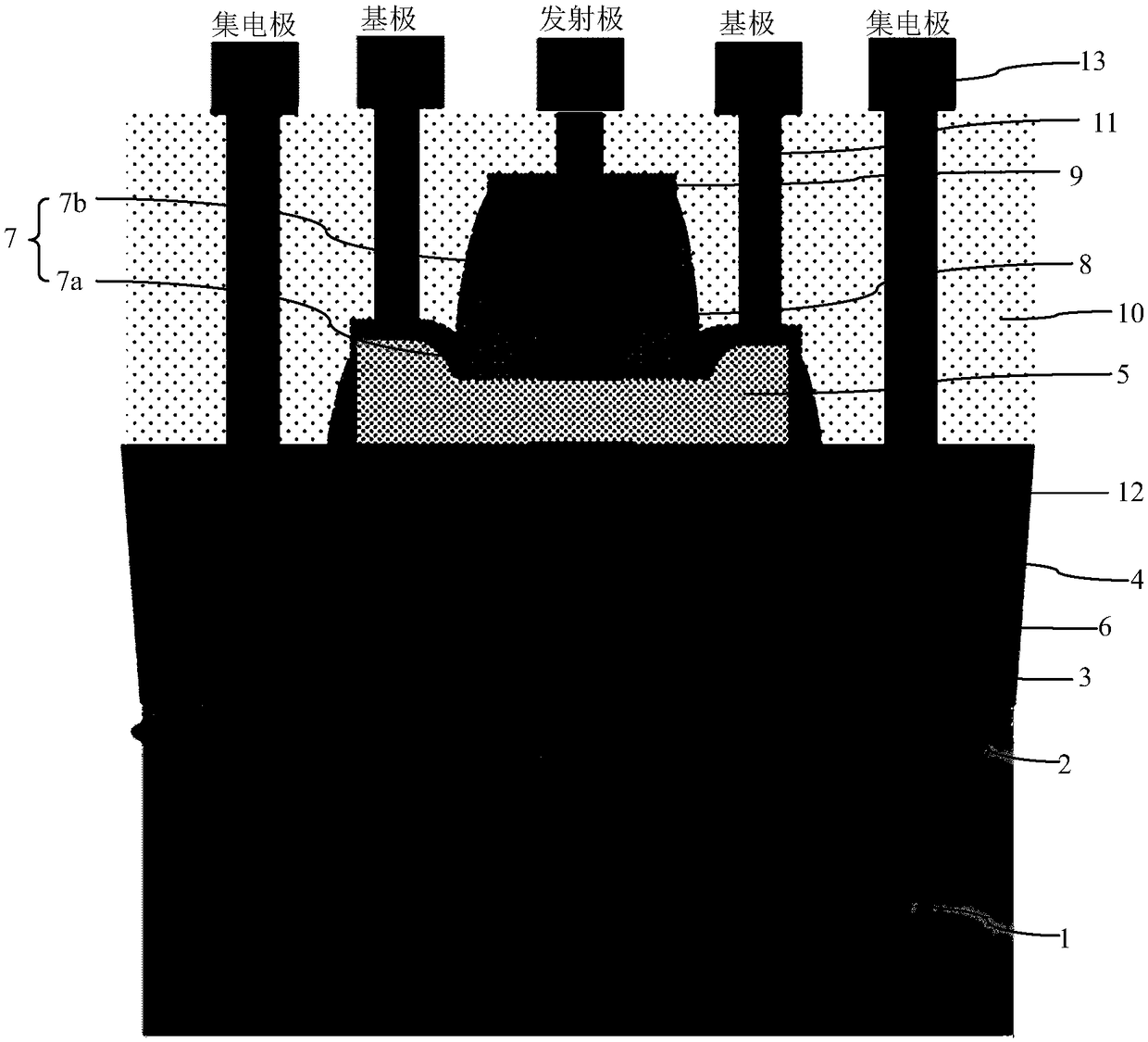

[0065] Such as figure 2 As shown, it is a schematic diagram of the structure of a silicon-germanium heterojunction bipolar transistor according to an embodiment of the present invention; , characterized in that the silicon-germanium heterojunction bipolar transistor comprises:

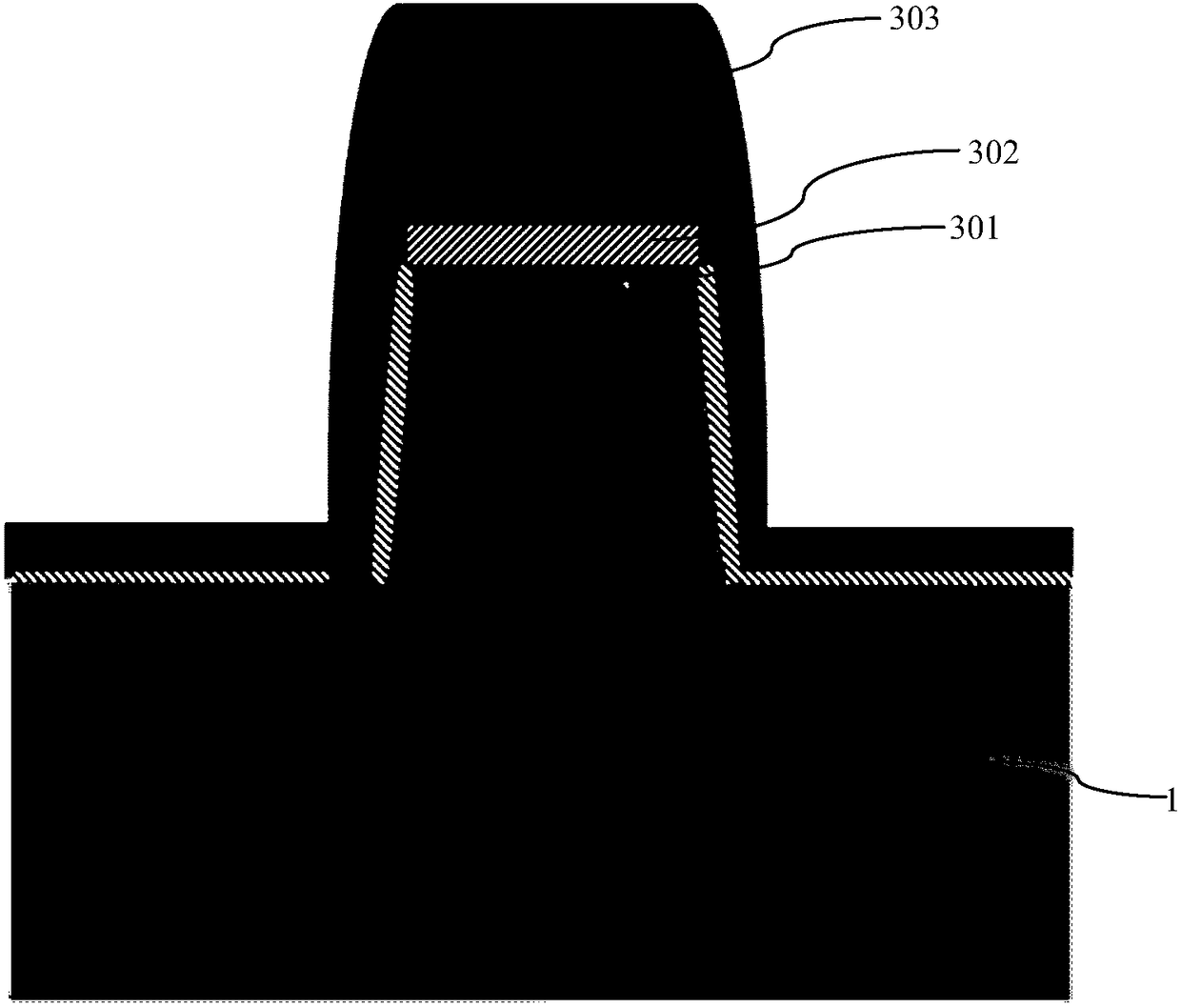

[0066] A collector region, including an overall collector region 3 and a partial collector region 6, the overall collector region 3 is composed of a first N-type ion implantation region formed in the entire active region; in the first N A second N-type ion implantation region is superimposed in a local area of the N-type ion implantation region, and the local collector region 6 is formed by overlapping the second N-type ion implantation region and the first N-type ion implantation region.

[0067] The pseudo-buried layer 2 is composed of a heavily doped third N-type ion implantation region formed at the bottom of the field oxide layer 4 on both sides of the active region, the pseudo-buried layer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com