Zinc indium tin oxide-based film transistor and manufacturing method thereof

A thin-film transistor and oxide-based technology, applied in the field of electronic information, can solve the problems of low mobility and high preparation temperature of thin-film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The embodiment of the present invention provides a zinc indium tin oxide based thin film transistor and its manufacturing method, which is composed of Zn x In y sn z O:(Li a ,N b ) material to prepare the active layer, use SiO 2 And the high-k material is used as an insulating layer to obtain a transparent thin film transistor. The problems of low mobility of commercial thin film transistors and high preparation temperature of high mobility thin film transistors are solved.

[0071] One aspect of the present invention provides a method for manufacturing a zinc indium tin oxide based thin film transistor.

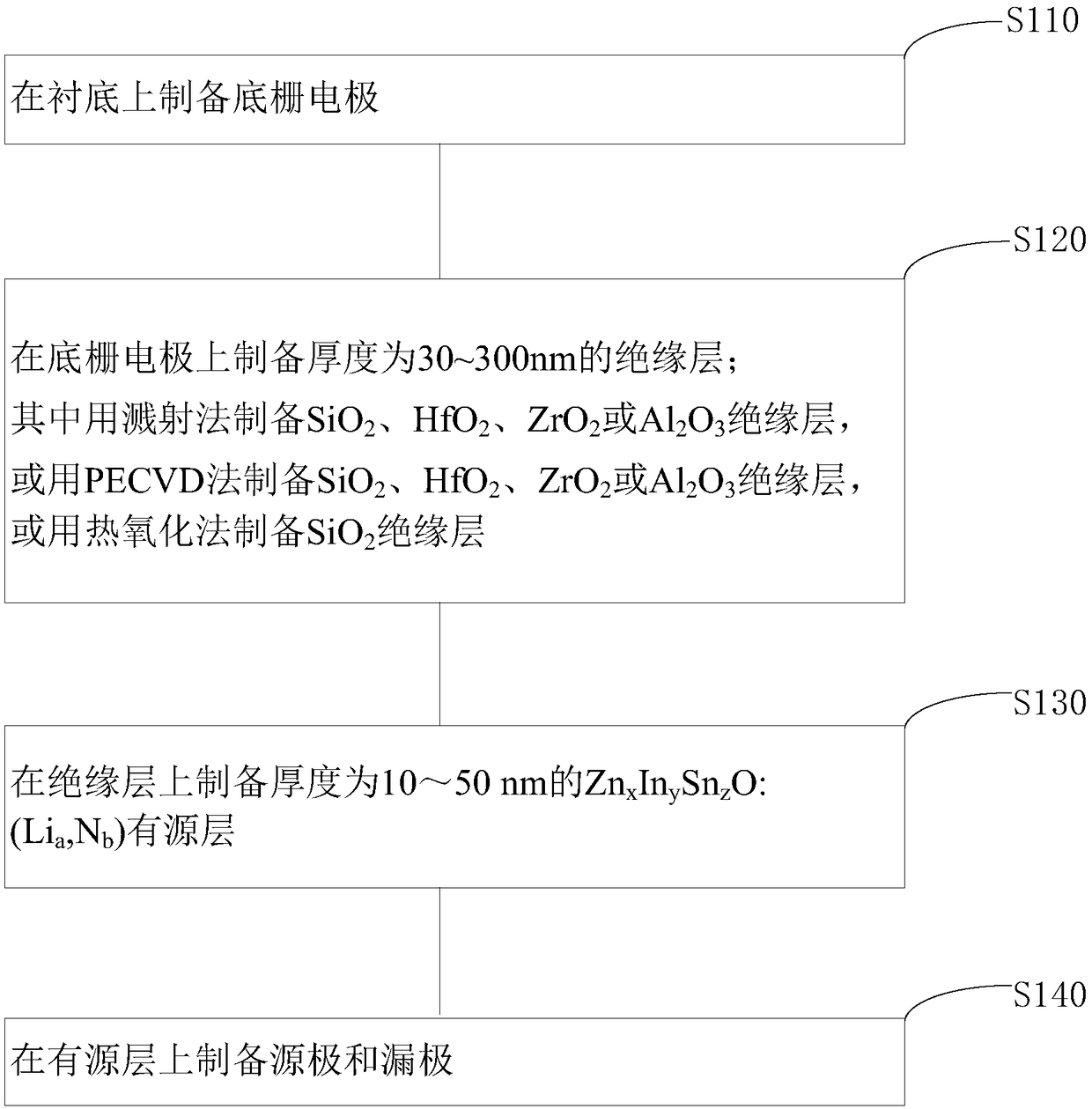

[0072] The processing flow of a method for manufacturing a zinc indium tin oxide-based thin film transistor provided in an embodiment of the present invention is as follows: figure 1 As shown, the following processing steps are included:

[0073] Step S110: preparing a bottom gate electrode on the substrate.

[0074] On a glass substrate, the bottom gate elect...

Embodiment 2

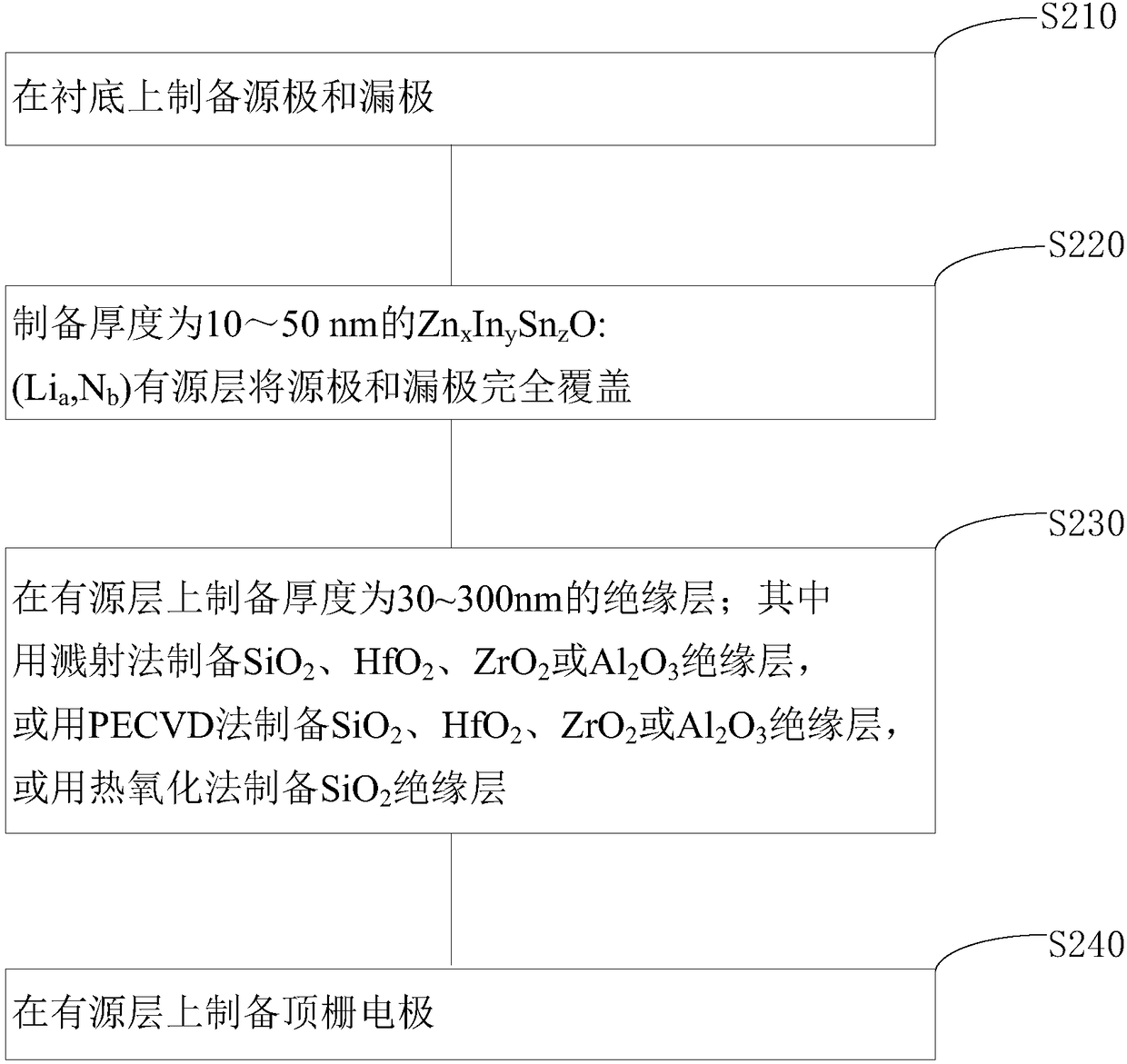

[0105] This embodiment provides a method for manufacturing a zinc indium tin oxide-based thin film transistor, and its specific implementation steps are as follows:

[0106] Step 1: preparing an ITO bottom gate on a glass substrate.

[0107] Step 2: Prepare an insulating layer on the electrode prepared in step 1, and grow the insulating layer as HfO 2 , with a thickness of 30nm.

[0108] Step 3: Prepare Zn by magnetron sputtering x In y sn z O:(Li a ,N b ) active layer, the thickness is 10nm, x=0.1, y=2, z=0.01, a=0.1, b=0, the sputtering power is 75W, the oxygen / argon pressure ratio is 30%, the growth temperature is room temperature, no annealing.

[0109] Step 4: Prepare Ti / Au source and drain electrodes by magnetron sputtering.

[0110] Produce ITO / HfO 2 / Zn x In y sn z O:(Li a ,N b ) / Ti / Au bottom gate structure zinc indium tin oxide based thin film transistor.

Embodiment 3

[0112] This embodiment provides a method for manufacturing a zinc indium tin oxide-based thin film transistor, and its specific implementation steps are as follows:

[0113] Step 1: On the Si substrate, prepare SiO by thermal oxidation 2 The insulating layer has a thickness of 200 nm.

[0114] Step 2: Prepare Zn on the SiO2 insulating layer by magnetron sputtering x In y sn z O:(Li a ,N b ) active layer, the thickness is 20nm, x=1, y=1.1, z=0.1, a=0.01, b=0, sputtering power is 100W, oxygen / argon pressure ratio is 0%, growth temperature is room temperature, annealing The temperature is 320° C., and the annealing atmosphere is nitrogen.

[0115] Step 3: Prepare Al source, drain and bottom gate by thermal evaporation.

[0116] Produced Al / Si / SiO 2 / Zn x In y sn z O:(Li a ,N b ) / Al bottom gate structure zinc indium tin oxide based thin film transistor.

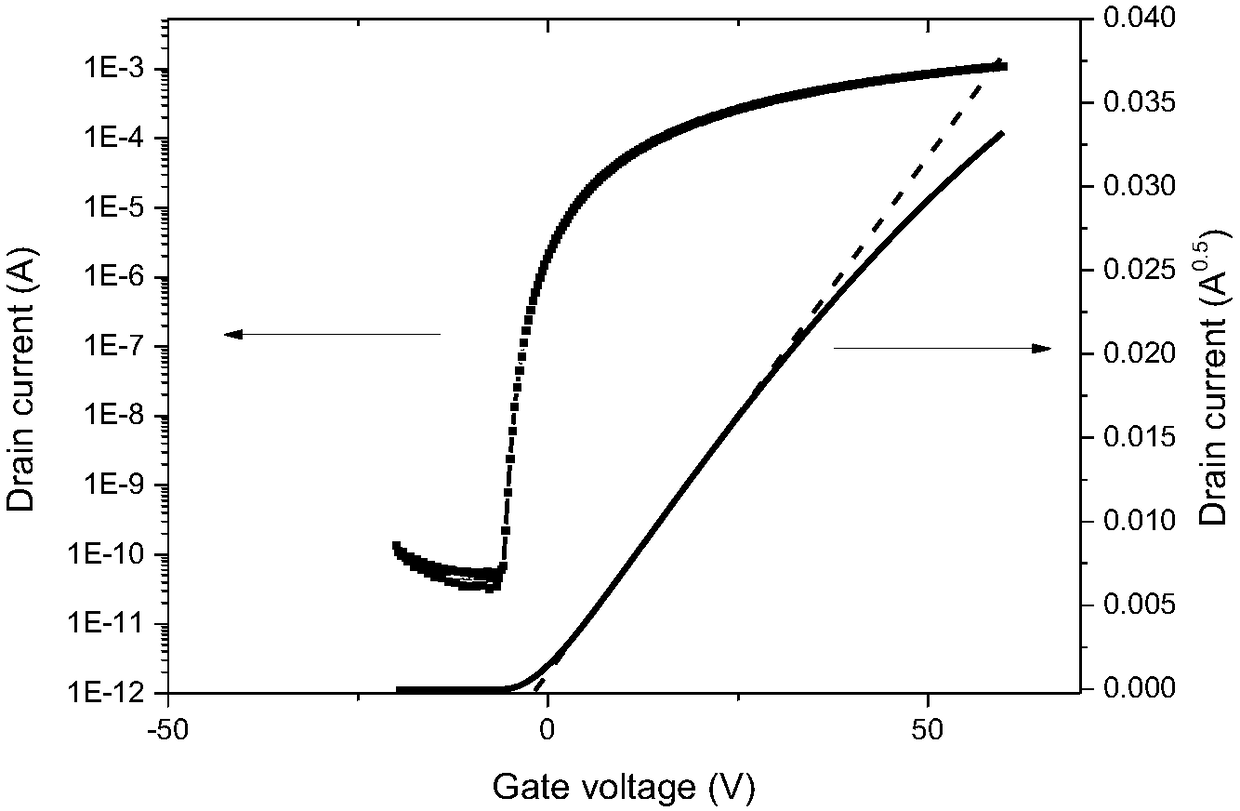

[0117] Zn produced by the above-mentioned production method two x In y sn z O:(Li a ,N b ) thin film transis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com