A method for controllable preparation of zno thin films

A thin film and solution technology, which is applied in the field of low-temperature preparation of high-quality ZnO thin films with controllable morphology, can solve the problems of long preparation cycle, high preparation temperature, and difficulty in obtaining uniform appearance, so as to shorten the drying process and reduce the production cost. The effect of temperature and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

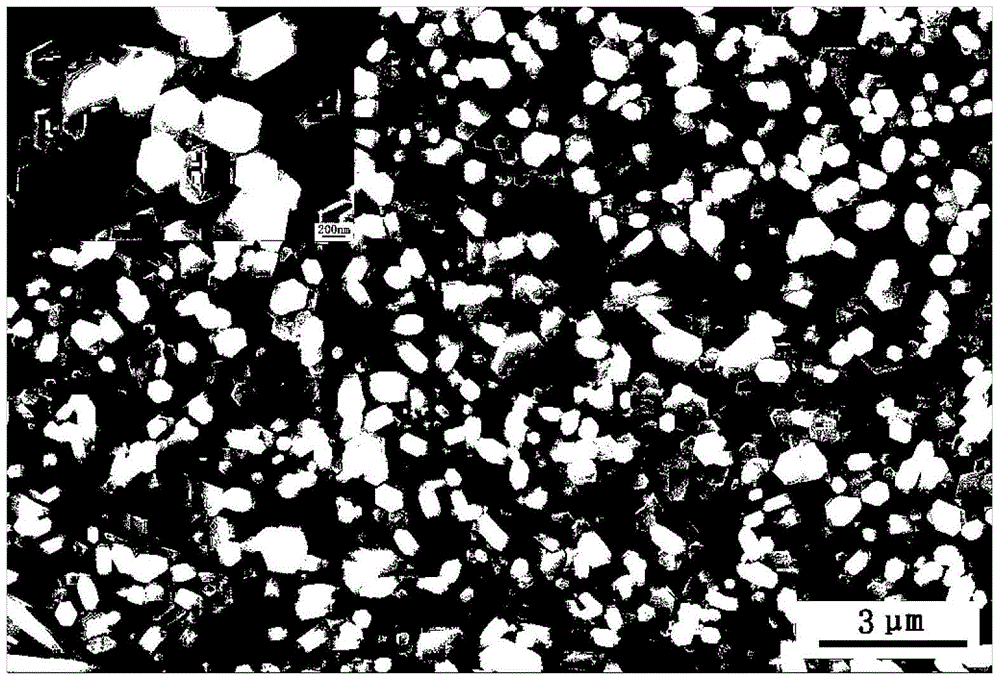

Image

Examples

preparation example 1

[0030] (1) The long strips cut from the Zn sheets are lightly polished with sandpaper to remove obvious stains on the surface;

[0031] (2) Clean the Zn sheet with dilute hydrochloric acid: dilute hydrochloric acid treatment 3 times, each time is 20 seconds, should be cleaned in deionized water for 10 seconds after each cleaning in dilute hydrochloric acid;

[0032] (3) The Zn sheets after pickling were ultrasonically cleaned with acetone and deionized water respectively, and the ultrasonic cleaning time was 15 minutes;

[0033] (4) ZnCl 2 The solid particles are ground into powdery particles, and 0.054g of ZnCl is weighed 2 powder, made up 80 mL of ZnCl with deionized water 2 solution. Then stir with a glass rod to fully dissolve;

[0034] (5) The beaker is sealed, and the ZnCl 2 The solution was ultrasonically treated for 10 minutes until an emulsion appeared at the bottom of the beaker;

[0035] (6) Place the processed Zn sheet vertically on the ZnCl 2 in solution; ...

specific preparation example 2

[0040] (1) The long strips cut from the Zn sheets are lightly polished with sandpaper to remove obvious stains on the surface;

[0041] (2) Clean the Zn sheet with dilute hydrochloric acid: dilute hydrochloric acid treatment 3 times, each time is 20 seconds, should be cleaned in deionized water for 10 seconds after each cleaning in dilute hydrochloric acid;

[0042] (3) The Zn sheets after pickling were ultrasonically cleaned with acetone and deionized water respectively, and the ultrasonic cleaning time was 15 minutes;

[0043] (4) ZnCl 2 The solid particles are ground into powdery particles, and 0.763g of ZnCl is weighed 2 powder, made up 80 mL of ZnCl with deionized water 2 solution. Then stir with a glass rod to fully dissolve;

[0044] (5) The beaker is sealed, and the ZnCl 2 The solution was ultrasonically treated for 10 minutes until an emulsion appeared at the bottom of the beaker;

[0045] (6) Place the processed Zn sheet vertically on the ZnCl 2 in solution; ...

specific preparation example 3

[0050] (1) The long strips cut from the Zn sheets are lightly polished with sandpaper to remove obvious stains on the surface;

[0051] (2) Clean the Zn sheet with dilute hydrochloric acid: dilute hydrochloric acid treatment 3 times, each time is 20 seconds, should be cleaned in deionized water for 10 seconds after each cleaning in dilute hydrochloric acid;

[0052](3) The Zn sheets after pickling were ultrasonically cleaned with acetone and deionized water respectively, and the ultrasonic cleaning time was 15 minutes;

[0053] (4) ZnCl 2 The solid particles are ground into powdery particles, and 0.763g of ZnCl is weighed 2 powder, made up 80 mL of ZnCl with deionized water 2 solution. Then stir with a glass rod to fully dissolve;

[0054] (5) The beaker is sealed, and the ZnCl 2 The solution was ultrasonically treated for 10 minutes until an emulsion appeared at the bottom of the beaker;

[0055] (6) Place the processed Zn sheet vertically on the ZnCl 2 in solution;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com