Composite flexible electrode as well as preparation method and application thereof

A flexible electrode and flexible technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of the positive conductivity to be improved, and achieve good application development prospects, increase the contact area, and reduce the effect of diffusion distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

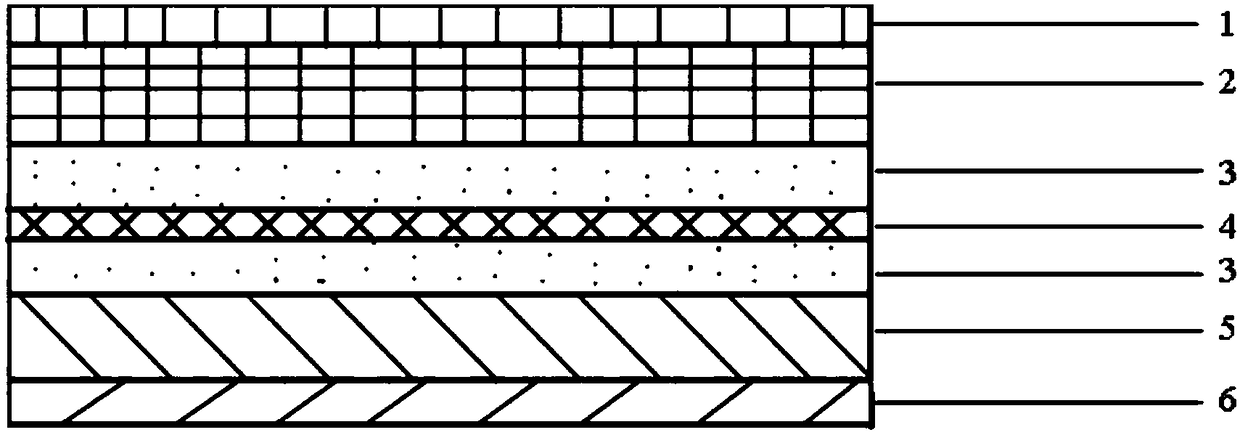

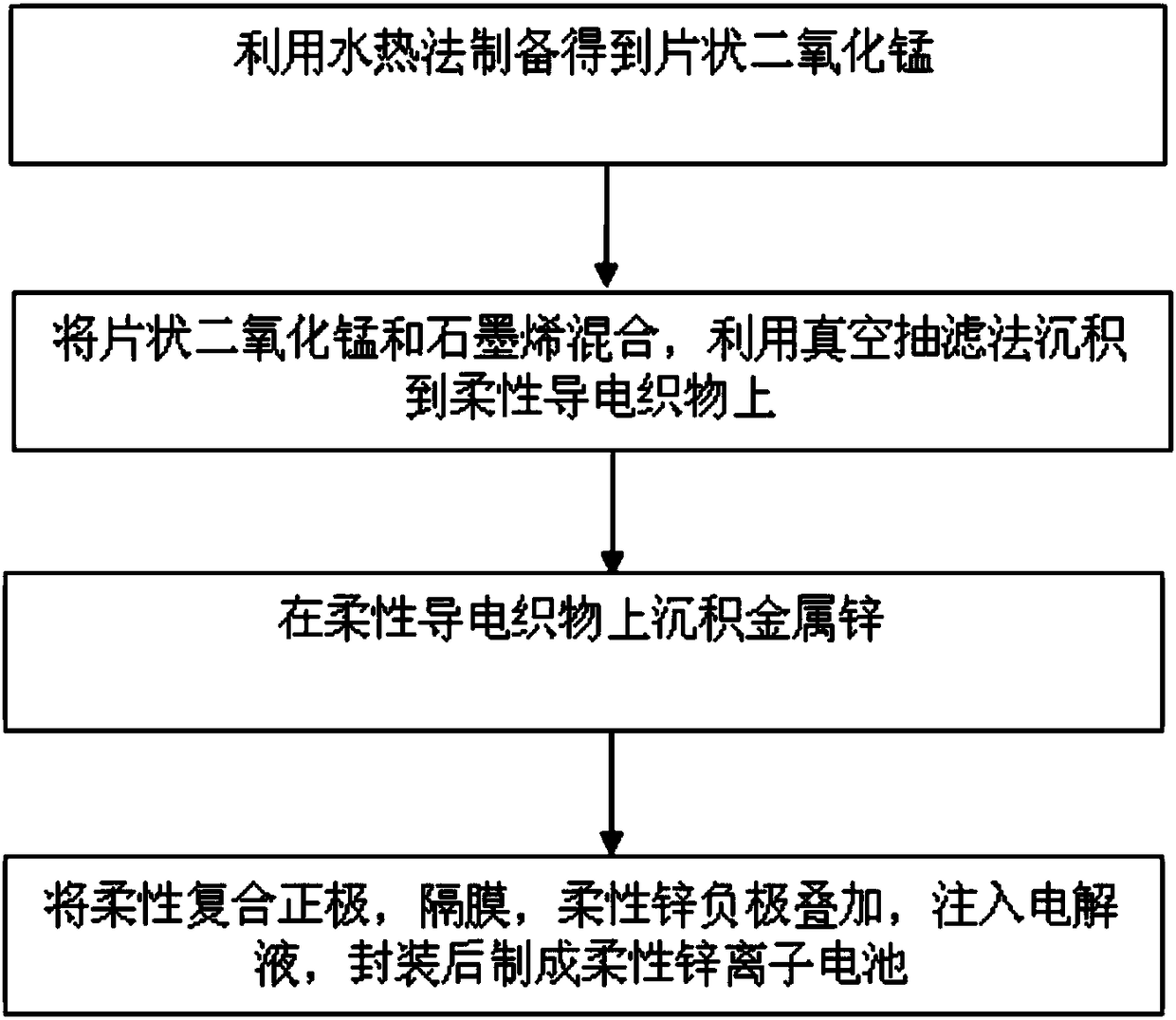

[0044] Correspondingly, the present application provides a method for preparing a composite flexible electrode, comprising the following steps: mixing sheet-like manganese dioxide and graphene and depositing it on a flexible current collector to obtain a composite flexible electrode.

[0045] In an embodiment of the present invention, the flaky manganese dioxide is prepared by a hydrothermal method; the size of the flaky manganese dioxide is 100nm-200nm. In the embodiment of the present invention, the manganese source compound is subjected to hydrothermal reaction in water, specifically, potassium permanganate (KMnO 4 ) and ammonium chloride (NH 4 Cl), mixed and dispersed in water at a molar ratio of 1:1, preferably hydrothermally reacted at 140° C. for 24 hours to obtain a precursor. Then, in the embodiment of the present invention, the obtained reaction product is filtered, washed, dried, and the sample is annealed, such as placed in an annealing furnace and heated at 300° ...

Embodiment 1

[0067] 1. Preparation of flaky manganese dioxide

[0068] 0.1264g KMnO 4 and 0.0428g NH 4Cl was mixed and dispersed in 40 mL of deionized water, moved to an autoclave, and reacted hydrothermally at 140° C. for 24 hours. After the hydrothermal reaction is finished, cool to room temperature, filter the reaction product, and wash repeatedly with absolute ethanol and deionized water. After drying at 60° C. for 2 hours, the sample was placed in an annealing furnace and heated at 300° C. for 1 hour in an air atmosphere to obtain 50 mg of flaky manganese dioxide. The SEM of the obtained flaky manganese dioxide is as image 3 shown by image 3 It can be seen that the prepared manganese dioxide is in the shape of nano flakes, and the size is 100nm-200nm.

[0069] 2. Preparation of sheet-like manganese dioxide and graphene composite electrodes

[0070] Mix and disperse 6 mg of the obtained flaky manganese dioxide and 1.5 mg of reduced graphene oxide (rGO, supplier: XF NANO, sheet ...

Embodiment 2

[0079] 0.1264g KMnO 4 and 0.0428g NH 4 Cl was mixed and dispersed in 40 mL of deionized water, moved to an autoclave, and reacted hydrothermally at 140° C. for 24 hours. After the hydrothermal reaction is finished, cool to room temperature, filter the reaction product, and wash repeatedly with absolute ethanol and deionized water. After drying at 60°C for 2 hours, the sample was placed in an annealing furnace and heated at 300°C for 1 hour in an air atmosphere to obtain flaky manganese dioxide. The prepared manganese dioxide is in the shape of nano flakes, and the size is 100nm-200nm.

[0080] Mix and disperse 6 mg of the obtained flaky manganese dioxide and 1.06 mg of reduced graphene oxide (rGO, supplier: XF NANO, sheet diameter 0.5 μm-5 μm, thickness 0.8 nm-1.2 nm) in 3 mL isopropanol solution, Ultrasound for 2 hours, and then use vacuum filtration to deposit the flake manganese dioxide and rGO mixture on conductive carbon cloth (1cm×2cm, thickness 0.33mm, resistance les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com