Hydrogel material containing macrocyclic rare earth complex and preparation method and application thereof

A technology of rare earth complexes and hydrogels, which is applied in the fields of analytical materials, luminescent materials, and material excitation analysis. It can solve the problems of reduced fluorescence intensity, difficult biodegradation, and poor biocompatibility, and achieves high color purity and easy degradation. , post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

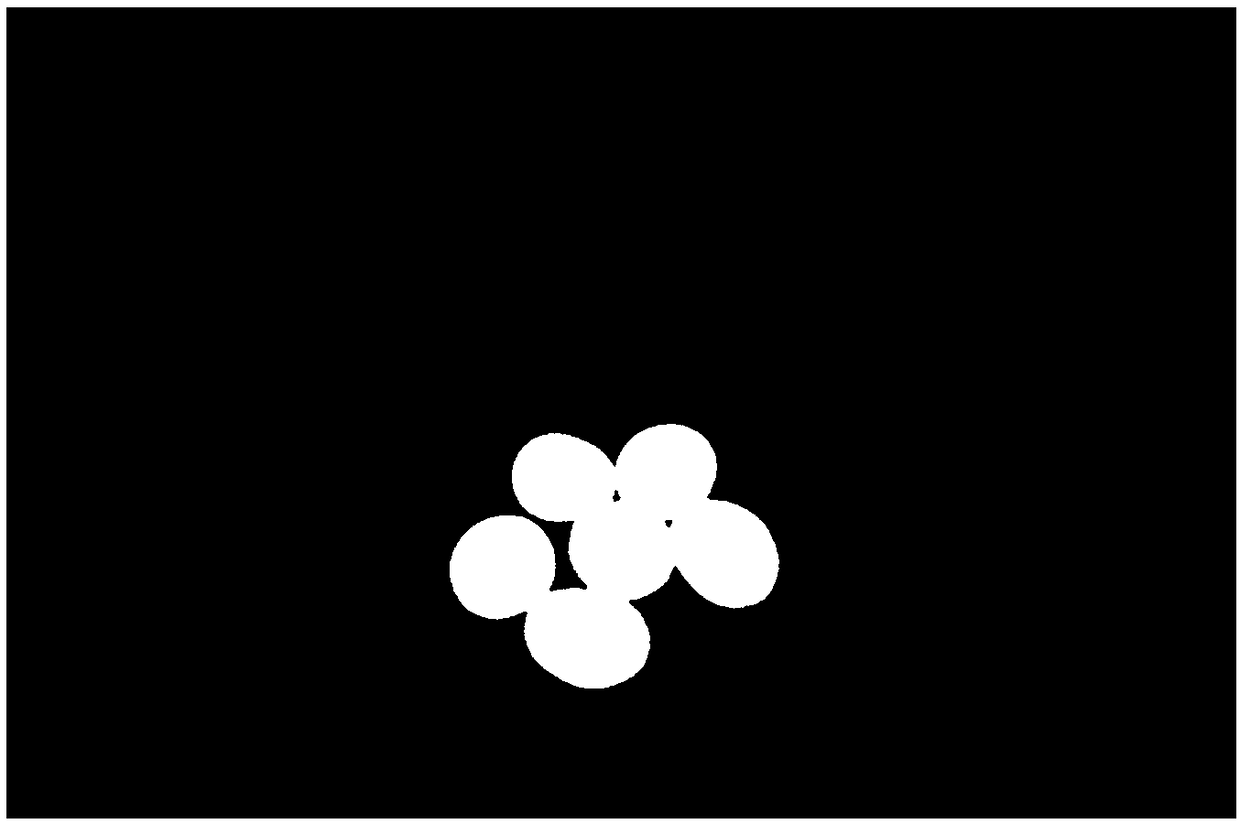

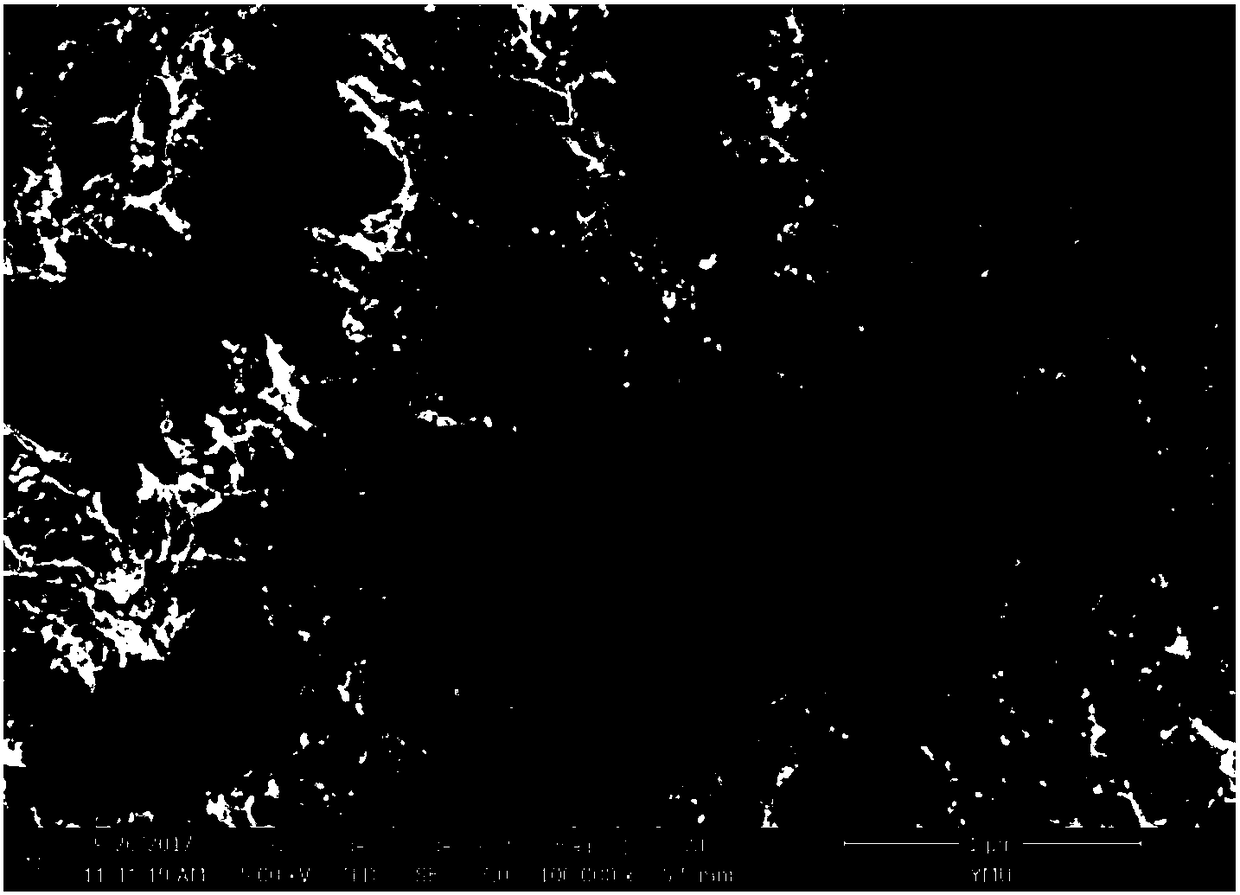

[0033] Add 0.5 g of sodium alginate into 100 mL of deionized water, and stir magnetically at room temperature until completely dissolved. Then, using a medical syringe, sodium alginate sol was added dropwise to 50mL of 0.03M terbium trichloride aqueous solution, and after aging for 24 hours, it was fully washed with deionized water to obtain sodium alginate / Tb 3+ Hydrogel spheres. Weigh 0.2 g of tetrakis(4-carboxyphenyl) porphine, add 40 mL of deionized water, adjust the pH value with 0.1 M sodium hydroxide dilute solution, and make the pH of the solution reach 9. Alginate / Tb 3+ The hydrogel pellets were added to an aqueous solution of tetrakis(4-carboxyphenyl)porphine sodium salt, stirred slowly on a magnetic stirrer for 12 hours, and then fully washed with deionized water to remove residual salt. Finally, soak the obtained TCPP / Tb / Alg pellets with deionized water to obtain a luminescent hydrogel material.

Embodiment 2

[0035] Add 0.8 g of sodium alginate into 100 mL of deionized water, and stir magnetically at room temperature until it is completely dissolved and becomes a sol. Then, using a medical syringe, sodium alginate sol was added dropwise to 50mL 0.04M terbium trichloride aqueous solution, aged for 24 hours and then fully washed with deionized water to obtain sodium alginate / Tb 3+ Hydrogel spheres. Weigh 0.2 g of tetrakis(4-carboxyphenyl) porphine, add 40 mL of deionized water, adjust the pH value with 0.1 M sodium hydroxide dilute solution, and make the pH of the solution reach 10. Alginate / Tb 3+ The hydrogel pellets were added to an aqueous solution of tetrakis(4-carboxyphenyl)porphine sodium salt, stirred slowly on a magnetic stirrer for 12 hours, and then fully washed with deionized water to remove residual salt. Finally, soak the obtained TCPP / Tb / Alg pellets with deionized water to obtain a luminescent hydrogel material.

Embodiment 3

[0037] Add 1.0 g of sodium alginate into 100 mL of deionized water, and stir magnetically at room temperature until it is completely dissolved and becomes a sol. Then, using a medical syringe, sodium alginate sol was added dropwise to 50mL of 0.06M terbium trichloride aqueous solution, and after aging for 24 hours, it was fully washed with deionized water to obtain sodium alginate / Tb 3+ Hydrogel spheres. Weigh 0.4 g of tetrakis(4-carboxyphenyl) porphin, add 80 mL of deionized water, adjust the pH value with 0.1 M sodium hydroxide dilute solution, and make the pH of the solution reach 11. Alginate / Tb 3+ The hydrogel pellets were added to an aqueous solution of tetrakis(4-carboxyphenyl)porphine sodium salt, stirred slowly on a magnetic stirrer for 12 hours, and then fully washed with deionized water to remove residual salt. Finally, soak the obtained TCPP / Tb / Alg pellets with deionized water to obtain a luminescent hydrogel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com