Preparation method of viscosity reducing type polycarboxylic acid water reducing agent

A technology of viscous polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures and can solve the problems of the structure and molecular weight of the polycarboxylic acid water reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

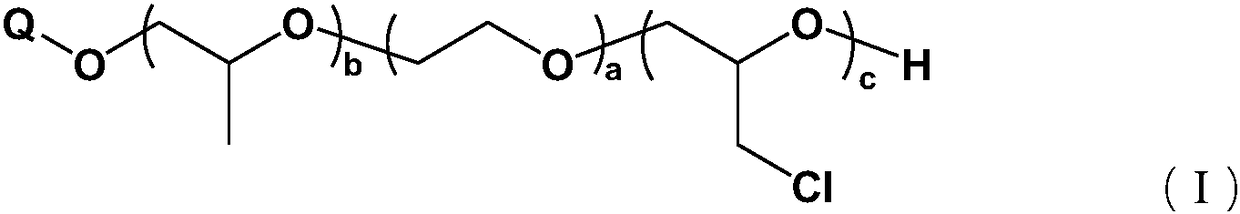

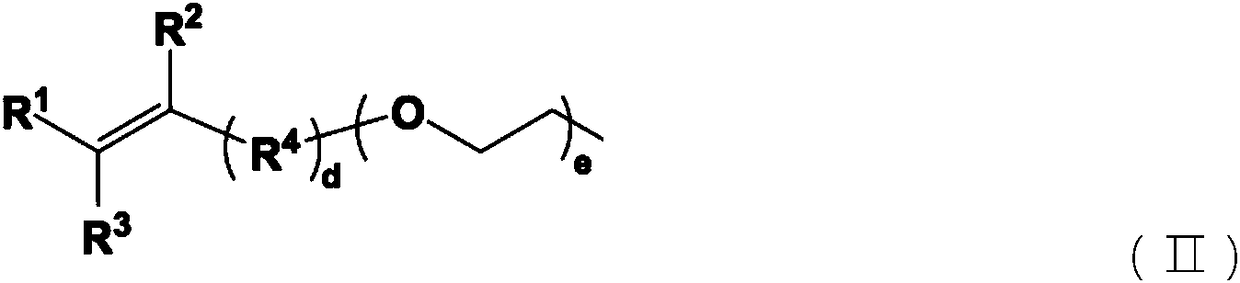

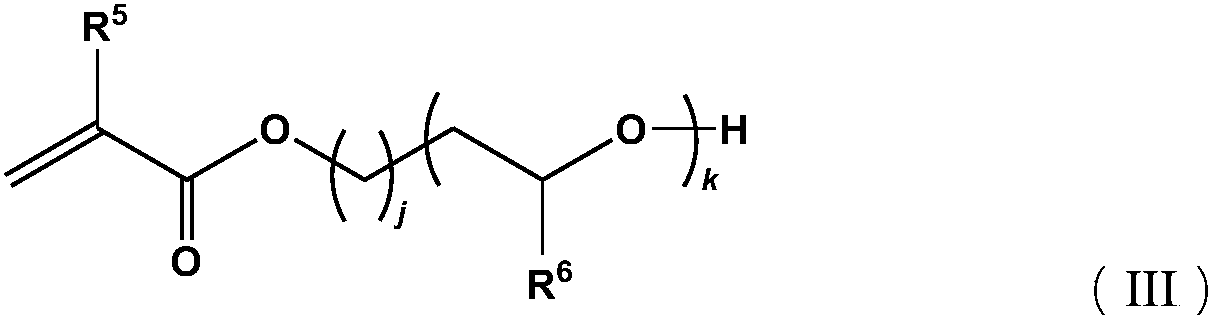

Method used

Image

Examples

Embodiment 1

[0063] Preparation of aminated polyether with a molecular weight of 635.

[0064] Chlorinated polyether preparation:

[0065] Initiator allyl alcohol, catalyst DMC. Weigh 100 parts of allyl alcohol and 1.1 parts of catalyst DMC, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 100° C., and 20 parts of propylene oxide was passed into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. When the pressure of the reactor no longer decreases, feed 411 parts of ethylene oxide into the reactor; when the pressure in the reactor no longer decreases, continue to feed 159 parts of epichlorohydrin into the reactor, and maintain the reactor during the feeding process. The temperature is between 110-130°C and the pressure is between 0.2-0.4MPa. After the feeding of epichlorohydrin is com...

Embodiment 2

[0081] Addition reaction of aminated polyether M1 with methyl acrylate.

[0082] Weigh 300 parts of aminated polyether M1 and 93 parts of catalyst NKC-93, put the above materials into the reactor and replace the reactor with nitrogen for 3 times to empty the air in the reactor. Keep the temperature of the reaction kettle at 50°C to prevent the aminated polyether from solidifying and separating out. Weigh 325 parts of methyl acrylate, add all of them into the reaction kettle within 30 minutes, and continue to fully stir at this temperature for 30 minutes. Then the pressure of the reactor was increased to 0.1 MPa, and the reaction was continued for 5 hours at 50°C. After the reaction, the catalyst NKC-9 is separated from the reaction material through a filter device and recycled for use; the remaining reaction material is passed through a vacuum distillation device to remove volatile substances in the material to obtain brown-yellow polycarboxylate group-containing The comonom...

Embodiment 3

[0096] Synthesis of polyether with a molecular weight of 1100.

[0097] The initiator is allyl alcohol, and the catalyst is potassium tert-butoxide. Weigh 100 parts of allyl alcohol and 1.5 parts of potassium tert-butoxide, put the above materials into the reactor, and evacuate the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 80° C., and 20 parts of ethylene oxide was introduced into the reaction kettle. After the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 1780 parts of ethylene oxide into the reactor. During the feeding process, keep the temperature of the reactor between 120-130°C and the pressure between 0.2-0.4MPa. After the addition of ethylene oxide is completed, keep the temperature at 100°C for 1h about. When the pressure of the reactor no longer decreases, reduce the temperature of the reactor to about 80°C, open the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com