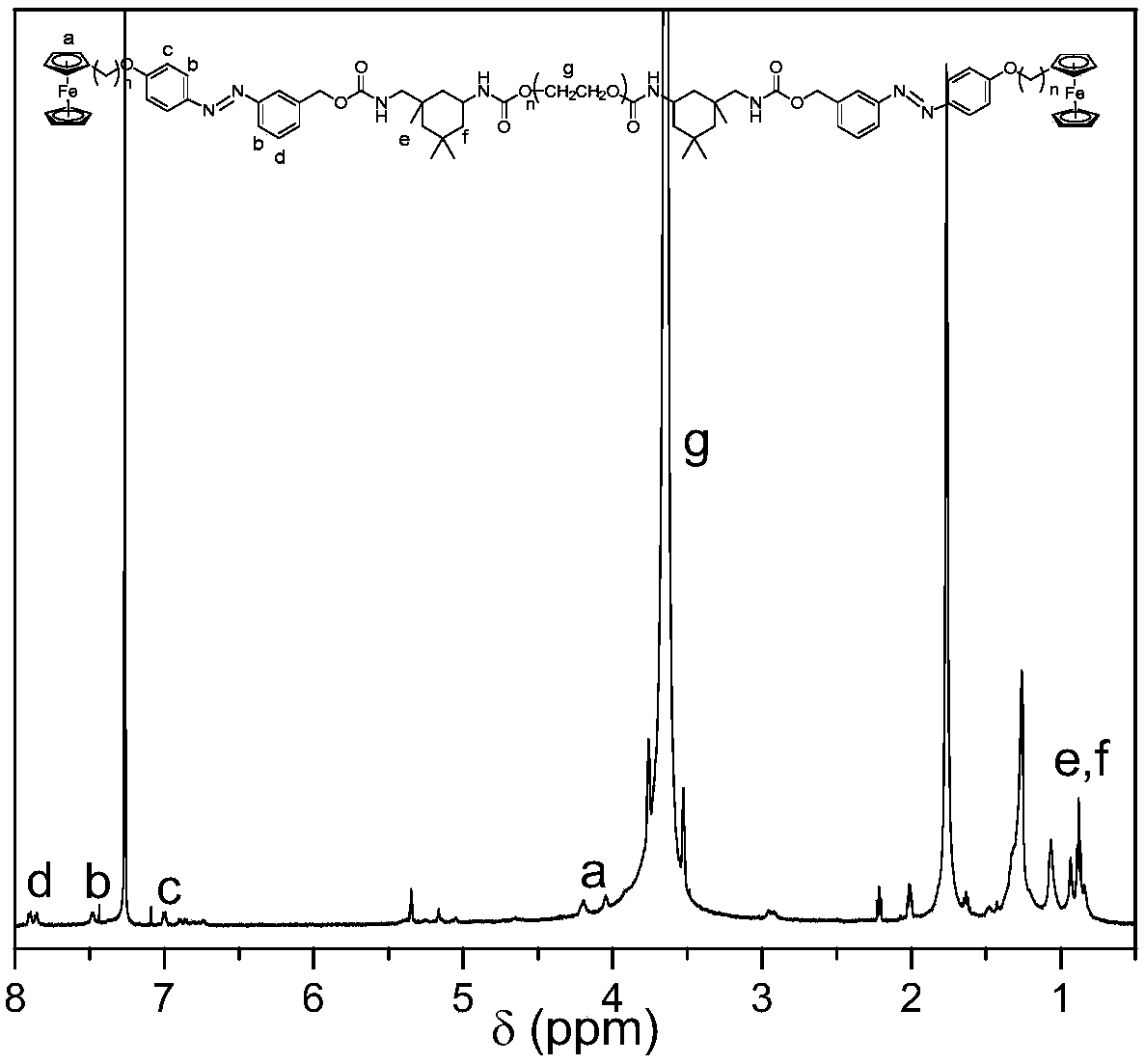

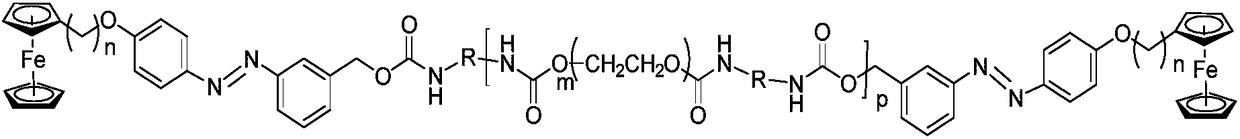

Polyurethane associative thickener with double stimulus response and preparation method thereof

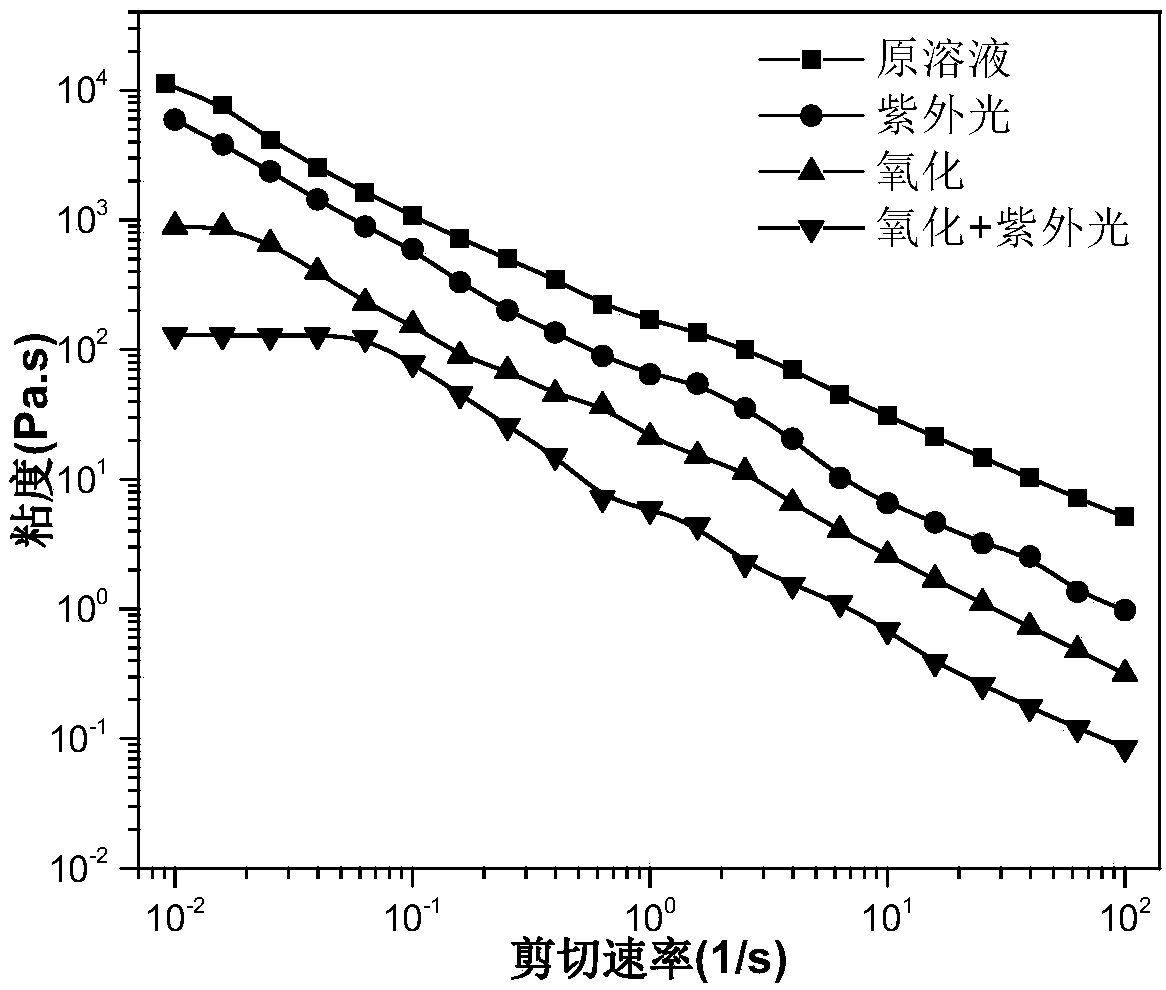

A dual-stimuli-responsive, associative thickener technology, applied in the field of hydrophobically modified ethoxylated polyurethane and polymer associative thickeners, can solve the problem of reduced association, reduced viscosity, weak intermolecular forces, etc. problem, to achieve good thickening performance and thickening performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) In a 250mL three-necked flask equipped with a magnetic stirrer and a condenser, add 3.6g (14.3mmol) 4-hydroxyazobenzyl alcohol, 5.93g (43.0mmol) anhydrous potassium carbonate, 4.6g (17.0mmol) Compound 11-bromo-n-undecylferrocene was added with 100 mL of DMF, nitrogen gas was passed into the reaction vessel, and stirred at room temperature to obtain a suspension. The temperature of the reaction suspension was maintained at 90°C, and the progress of the reaction was followed by thin-layer chromatography. After 18 hours, the reactant 4-hydroxyazobenzyl alcohol was completely reacted. The reaction suspension was filtered while it was hot, and the filtrate was collected. After the filtrate was cooled to room temperature, the filtrate was poured into 500 mL of saturated saline to obtain a light yellow precipitate. After filtration, the precipitate was washed with saturated saline and distilled water for 3 times, and then recrystallized twice with acetone at -3°C at low te...

Embodiment 2

[0049] (1) In a 250mL three-necked flask equipped with a magnetic stirrer and a condenser, add 3.6g (14.3mmol) 4-hydroxyazobenzyl alcohol, 4.56g (43.0mmol) anhydrous potassium carbonate, 3.9g (17.0mmol) Add 100mL of DMF to compound 8-chloro-n-octyl ferrocene, blow nitrogen into the reaction vessel, and stir at room temperature to obtain a suspension. The temperature of the reaction suspension was maintained at 90°C, and the progress of the reaction was followed by thin-layer chromatography. After 24 hours, the reactant 4-hydroxyazobenzyl alcohol was completely reacted. The reaction suspension was filtered while it was hot, and the filtrate was collected. After the filtrate was cooled to room temperature, the filtrate was poured into 500 mL of saturated saline to obtain a light yellow precipitate. After filtration, the precipitate was washed three times with saturated saline and distilled water successively, and then recrystallized twice with acetone at a low temperature of -3°...

Embodiment 3

[0060] (1) In a 250mL three-necked flask equipped with a magnetic stirrer and a condenser, add 3.6g (14.3mmol) of 4-hydroxyazobenzyl alcohol, 14g (43.0mmol) of anhydrous cesium carbonate, 4.6g (17.0mmol) of the compound 10-iodo-n-decyl ferrocene, and then add DMF 100mL, blow nitrogen into the reaction vessel, and stir at room temperature to obtain a suspension. The temperature of the reaction suspension was maintained at 90°C, and the progress of the reaction was followed by thin-layer chromatography. After 10 hours, the reactant 4-hydroxyazobenzyl alcohol was completely reacted. The reaction suspension was filtered while it was hot, and the filtrate was collected. After the filtrate was cooled to room temperature, the filtrate was poured into 500 mL of saturated saline to obtain a light yellow precipitate. After filtration, the precipitate was washed three times with saturated saline and distilled water successively, and then recrystallized three times with acetone at a low t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com