A kind of quick-drying soft porcelain genuine stone paint and preparation method thereof

A technology of real stone paint and soft porcelain, applied in the direction of coating, etc., can solve the problems of not being able to process large plates, block materials that cannot be transported, and high cost, and achieve the effects of increasing drying speed, preventing gelation, and controlling paint viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of the quick-drying soft porcelain genuine stone paint, comprising the following steps: base water glass and quaternary ammonium salt, and continuously stir for 10-15 minutes at a rotating speed of 400-800 rpm;

[0034] b: Under normal temperature and pressure, continue to add silane coupling agent and defoamer to the container with agitator, and disperse for 5-15 minutes at the speed of 600-900 rpm;

[0035] c: At normal temperature and pressure, add 120-180 mesh quartz sand and 40-80 mesh quartz sand to the mixture obtained in step b, and disperse at 700-1100 rpm for 5-15 minutes, then stand still for 20-50 minutes Minutes, you can get quick-drying soft porcelain real stone paint.

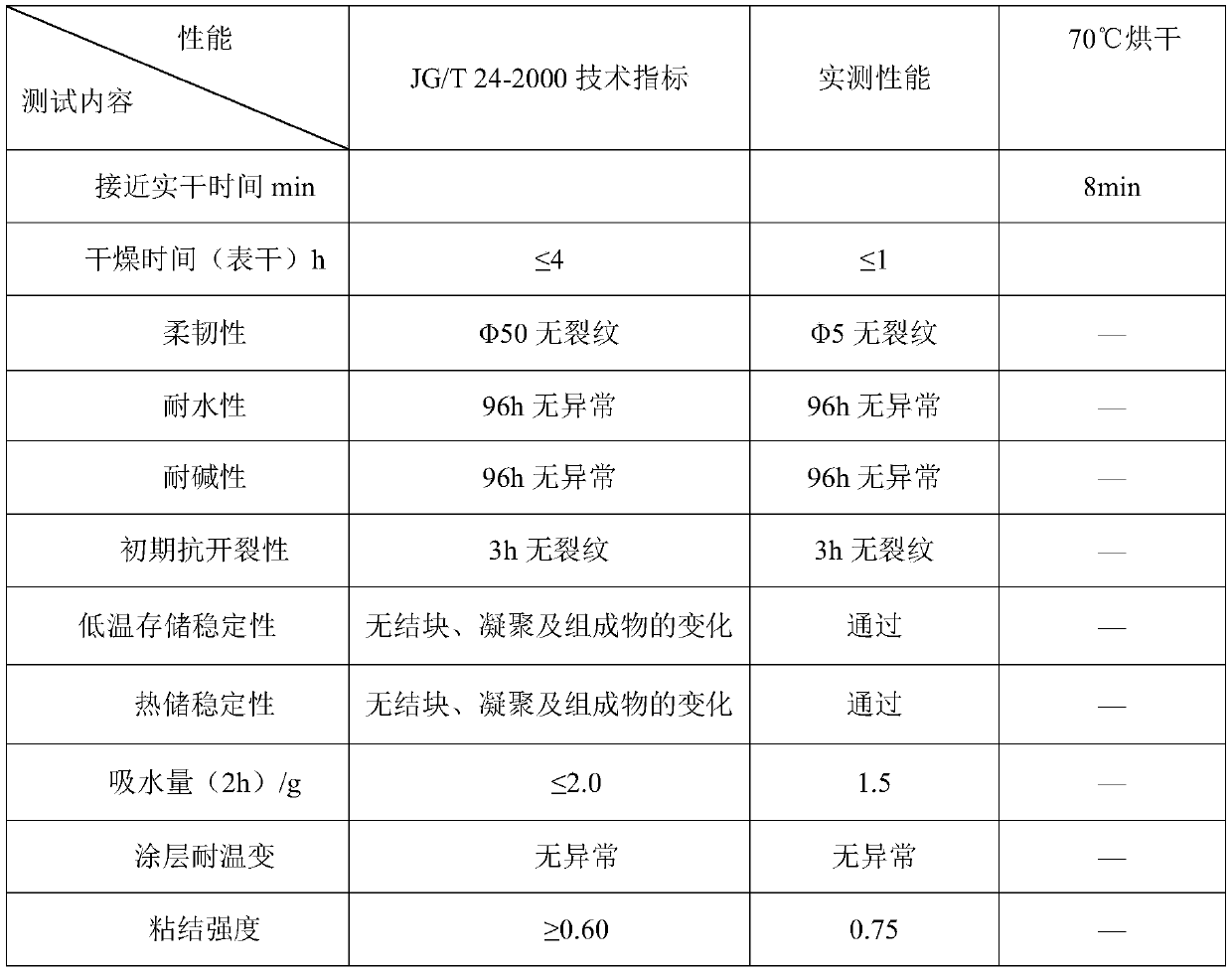

Embodiment 1

[0037]A quick-drying soft porcelain real stone paint, comprising the following raw materials in parts by weight: 15 parts of quick-drying acrylic emulsion, 5 parts of potassium-based water glass, 30 parts of 120-180 mesh quartz sand, 20 parts of 40-80 mesh quartz sand, 1 part of silane coupling agent, 0.05 part of defoamer, 0.1 part of quaternary ammonium salt.

[0038] The quick-drying acrylic emulsion is formed by copolymerizing monomers comprising styrene, methyl methacrylate, butyl acrylate, isooctyl acrylate, hydroxyethyl ester, ethylene trimethoxysilane, and 2-hydroxyethyl methacrylate As a result, the molar ratio of the above components is 20:10:10:5:1:1:2.

[0039] The potassium-based water glass is one with a modulus of 2.0-4.0.

[0040] The 120-180 mesh quartz sand is natural colored sand.

[0041] The 40-80 mesh quartz sand is sintered sand.

[0042] The silane coupling agent is 3-aminopropyltriethoxysilane.

[0043] The defoamer is fumed silicon dioxide.

[00...

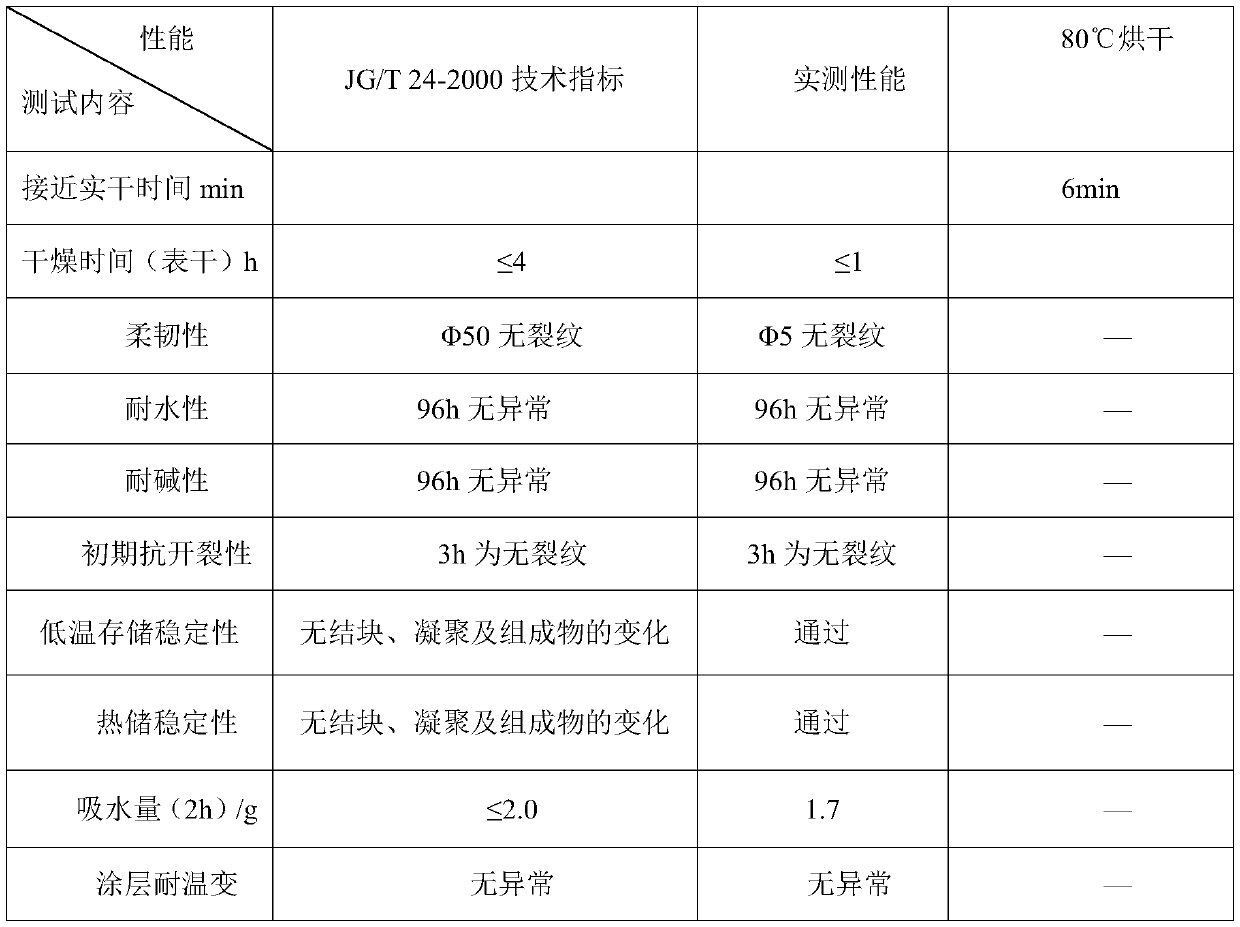

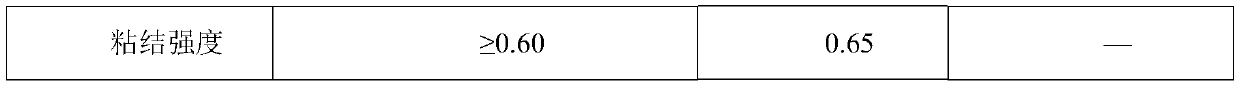

Embodiment 2

[0054] A quick-drying soft porcelain real stone paint, comprising the following raw materials in parts by weight: 20 parts of quick-drying acrylic emulsion, 10 parts of potassium-based water glass, 40 parts of 120-180 mesh quartz sand, 25 parts of 40-80 mesh quartz sand, 2 parts of silane coupling agent, 0.15 part of defoamer, 0.5 part of quaternary ammonium salt.

[0055] The quick-drying acrylic emulsion is formed by copolymerizing monomers comprising styrene, methyl methacrylate, butyl acrylate, isooctyl acrylate, hydroxyethyl ester, ethylene trimethoxysilane, and 2-hydroxyethyl methacrylate The molar ratio of the above components is 30:20:15:10:2:3:1.

[0056] The modulus of the potassium-based water glass is 2.0-4.0.

[0057] The 120-180 mesh quartz sand is sintered sand.

[0058] The 40-80 mesh quartz sand is dyed sand.

[0059] The silane coupling agent uses γ-methacryloxypropyltrimethoxysilane.

[0060] The defoamer is fumed silicon dioxide.

[0061] The quaternar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com