Preparation method of melanin stabilizing agent and preparation method of weather-resistant silane modified polyurethane sealing agent

A polyurethane sealant and silane modification technology, which is applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of high cost and cumbersome components, and prevent oxidation failure, eliminate ultraviolet rays, Effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

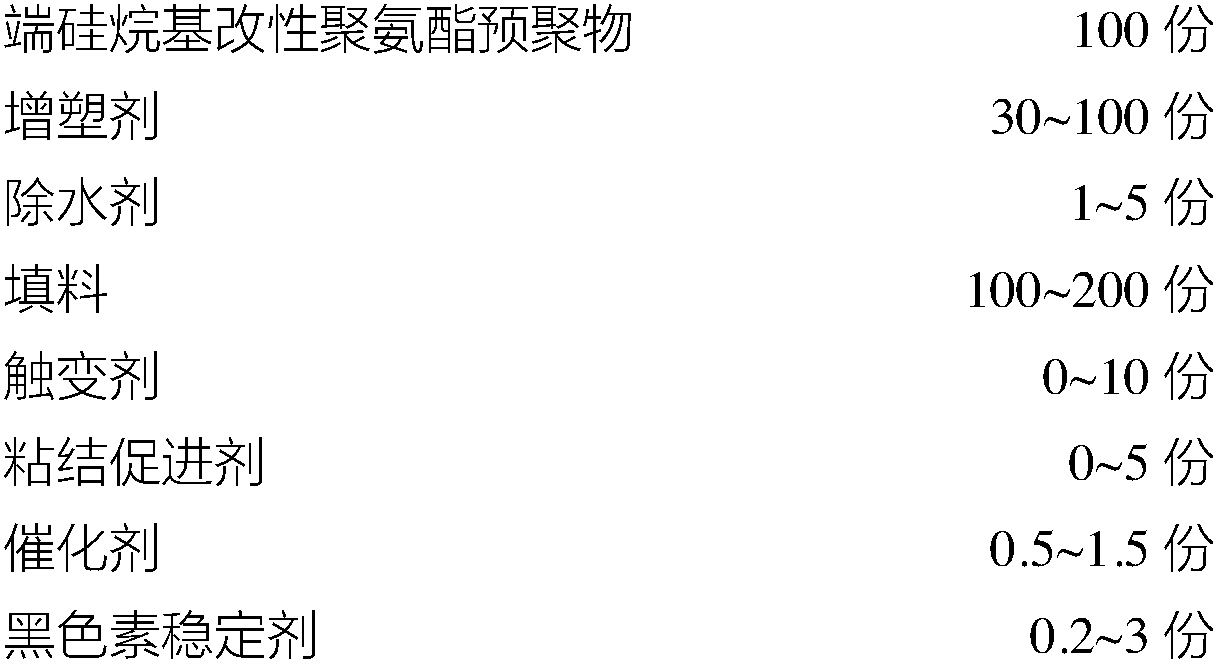

Method used

Image

Examples

Embodiment 1

[0044] Preparation of melanin stabilizer: remove the squid ink sac, remove the epidermis and internal reticular membrane, soak in equal volume deionized water at 4°C for 12h, centrifuge at 9000rpm for 15min, adjust the pH to 6.5, add 500u / g papain and collagen at 70°C Protease (mass ratio 1:1) was used for enzymolysis, the temperature was raised to 90°C for 10 minutes, washed with deionized water to pH 7.0, and freeze-dried to obtain melanin; the obtained melanin was weighed and dispersed in bis(1,2,2,6, 6-Pentamethyl-4-piperidinyl) sebacate (mass ratio 2:1), ultrasonication for 10 minutes to obtain melanin stabilizer MS-1.

Embodiment 2

[0046] Preparation of melanin stabilizer: remove the cuttlefish ink sac, remove the epidermis and internal reticular membrane, soak in equal volume deionized water at 0°C for 12h, centrifuge at 10,000rpm for 15min, adjust the pH to 7.0, add 300u / g neutral protease at 60°C Enzymolysis, heat up to 90°C for 10 minutes, wash with deionized water to pH 6.8, freeze-dry to obtain melanin; weigh the obtained melanin, disperse in bis(1-octyloxy-2,2,6,6-tetramethyl -4-piperidinyl) sebacate (mass ratio 1:1), ultrasonication for 5 minutes to obtain melanin stabilizer MS-2.

Embodiment 3

[0048]Preparation of melanin stabilizer: remove the cuttlefish ink sac, remove the epidermis and internal reticular membrane, soak in equal volume deionized water at 0°C for 12h, centrifuge at 10,000rpm for 20min, adjust the pH to 7.2, add 300u / g neutral protease at 65°C Enzymolysis, heat up to 70°C for 10 minutes, wash with deionized water to pH 7.2, freeze-dry to obtain melanin; weigh the obtained melanin, disperse in bis(1-octyloxy-2,2,6,6-tetramethyl -4-piperidinyl) sebacate (mass ratio 2:1), ultrasonication for 5 minutes to obtain melanin stabilizer MS-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com