SiAlCN wireless passive temperature sensor loaded with patch antenna and preparation method

A technology of temperature sensor and patch antenna, which is applied in the direction of antenna, thermometer, and thermometer with electric/magnetic elements that are directly sensitive to heat, etc. It can solve the problem of low working temperature, short test distance of wireless passive sensors, and difficult measurement methods. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

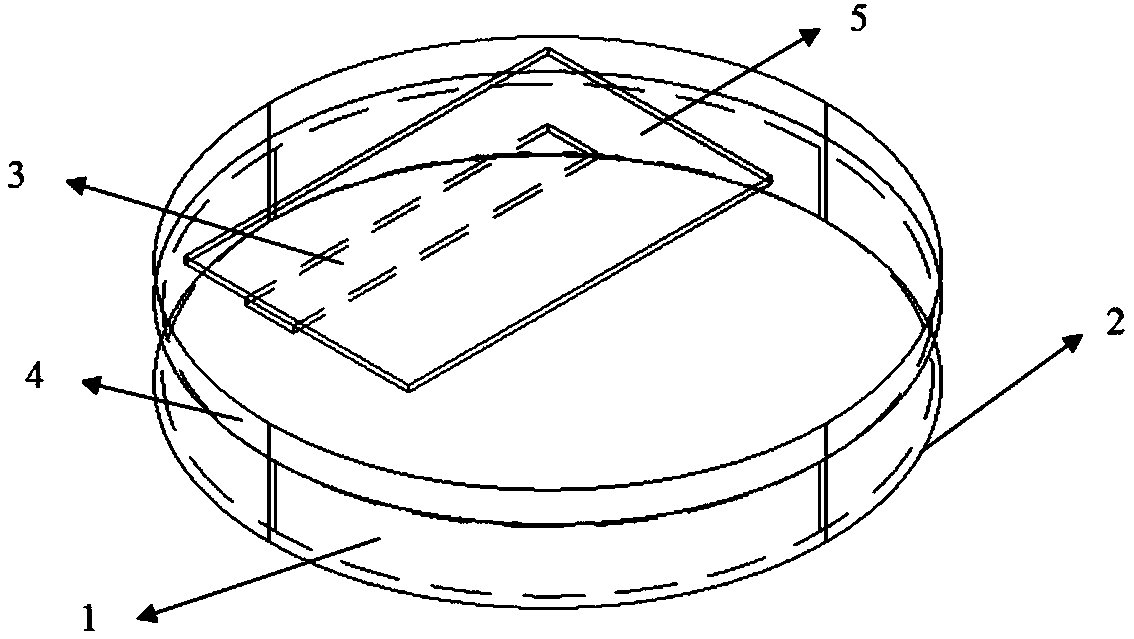

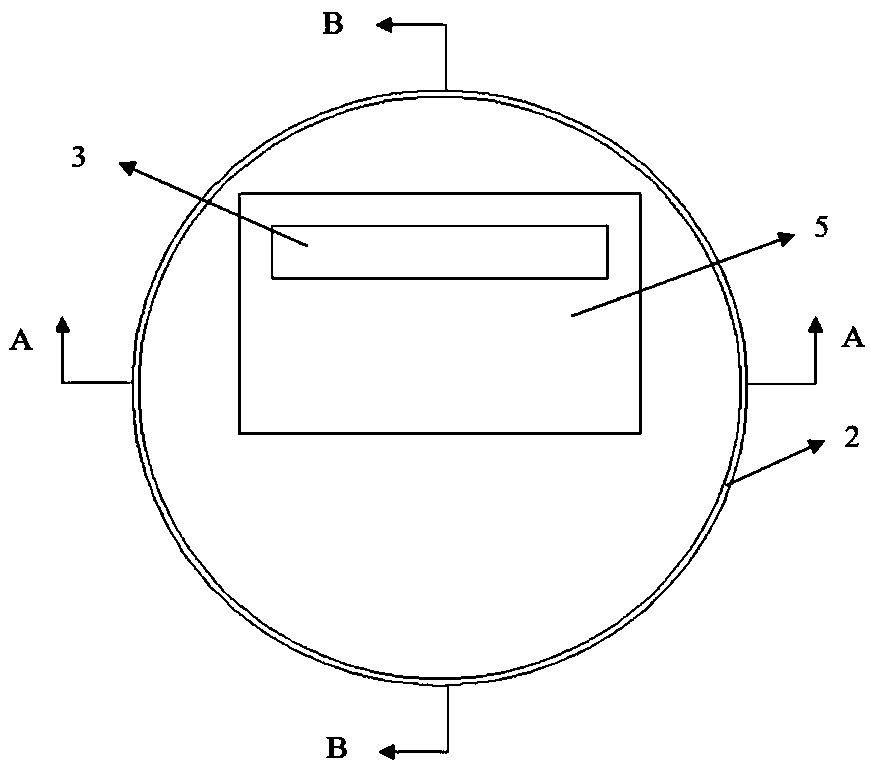

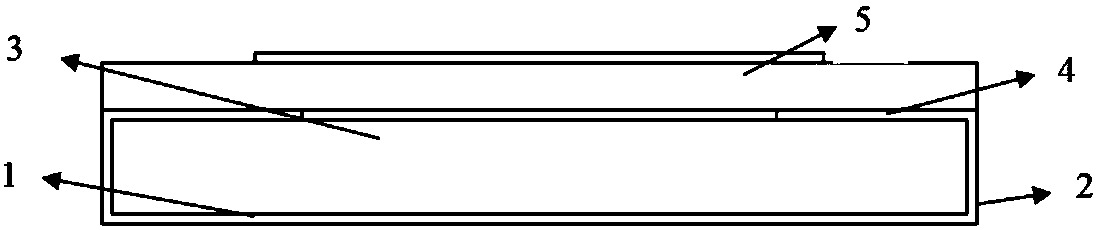

[0042] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

[0043] The preparation method of the SiAlCN wireless passive temperature sensor loaded with patch antenna comprises the following steps:

[0044] 1. Mix polysilazane and 0.3 g of aluminum sec-butoxide in a mass ratio of 90:10, and stir the mixture on a magnetic stirrer under the protection of nitrogen atmosphere for 24 hours at a temperature of 80°C. A light yellow precursor mixture was obtained.

[0045] 2. Pour the mixture into a tin foil box, put it into a tube furnace, and then raise the temperature to 160°C for 4 hours to carry out thermal crosslinking. The whole process is protected by a nitrogen atmosphere, and naturally cooled to room temperature to obtain a block precursor.

[0046] 3. Crush the obtained massive precursor body, and grind it into powder with a ball mill, with a particle diameter of about 1 μm. The frequency of the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com