Lithium battery positive electrode material and conductive additive

A technology of conductive additives and positive electrode materials, applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of harsh requirements, incomplete electrochemical performance, and high residual alkali content on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the lithium battery described in the present invention comprises:

[0029] Weighing the positive electrode active material of the lithium battery and additives selected from fluorine-containing alkyl compounds and / or weak acids, grinding and mixing to obtain the lithium positive electrode material containing the additive;

[0030] Mix the additive-containing lithium battery positive electrode material with the conductive agent acetylene black and the binder polyvinylidene fluoride (PVdF) in a nitrogen-methylpyrrolidone (NMP) solvent to obtain a slurry, wherein the additive-containing lithium battery positive electrode material , The mass ratio of conductive agent and binder is 85:10:5;

[0031] Coat the uniformly mixed slurry on an aluminum foil, and dry it under vacuum at 120°C for 12 hours to obtain a positive electrode for a lithium battery;

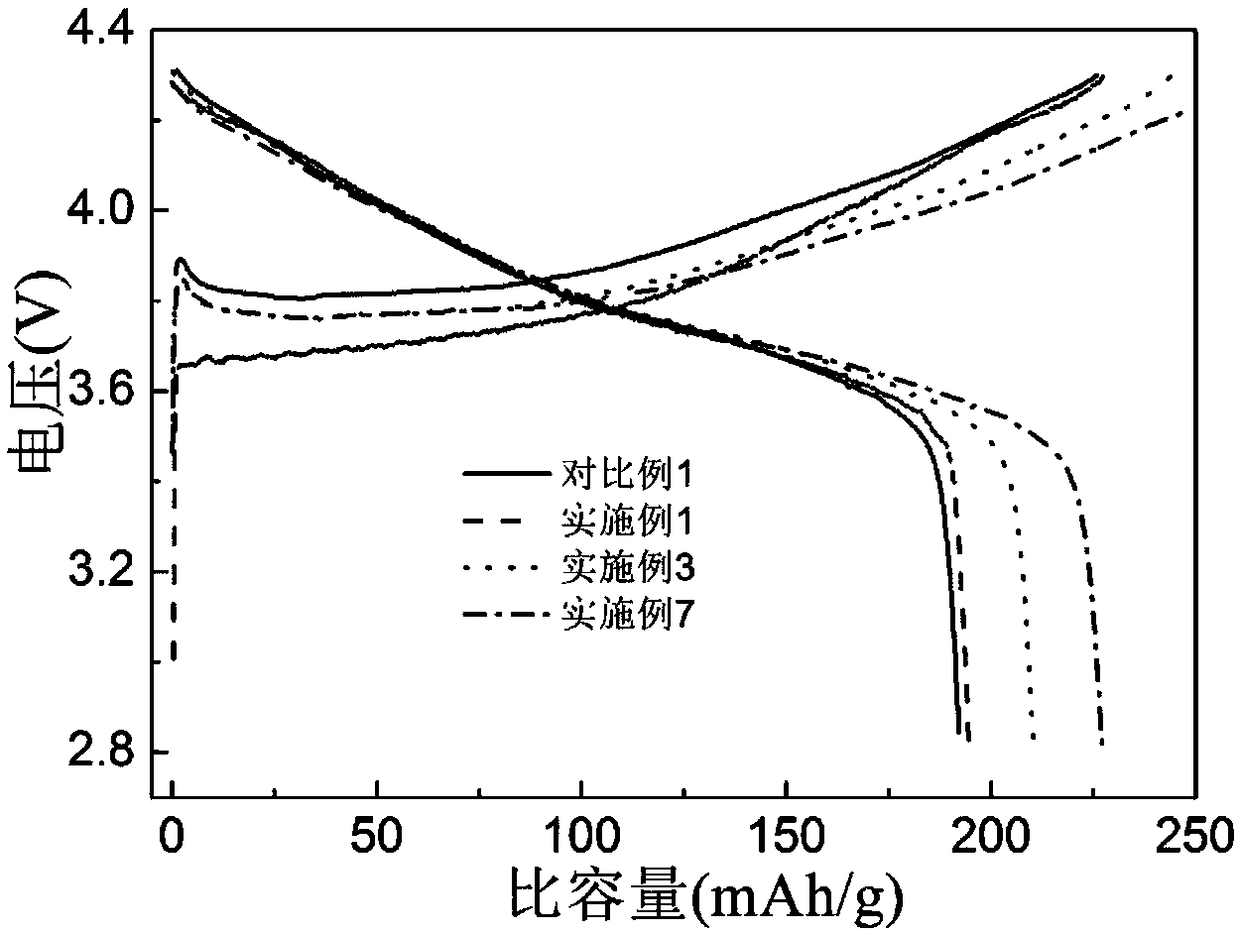

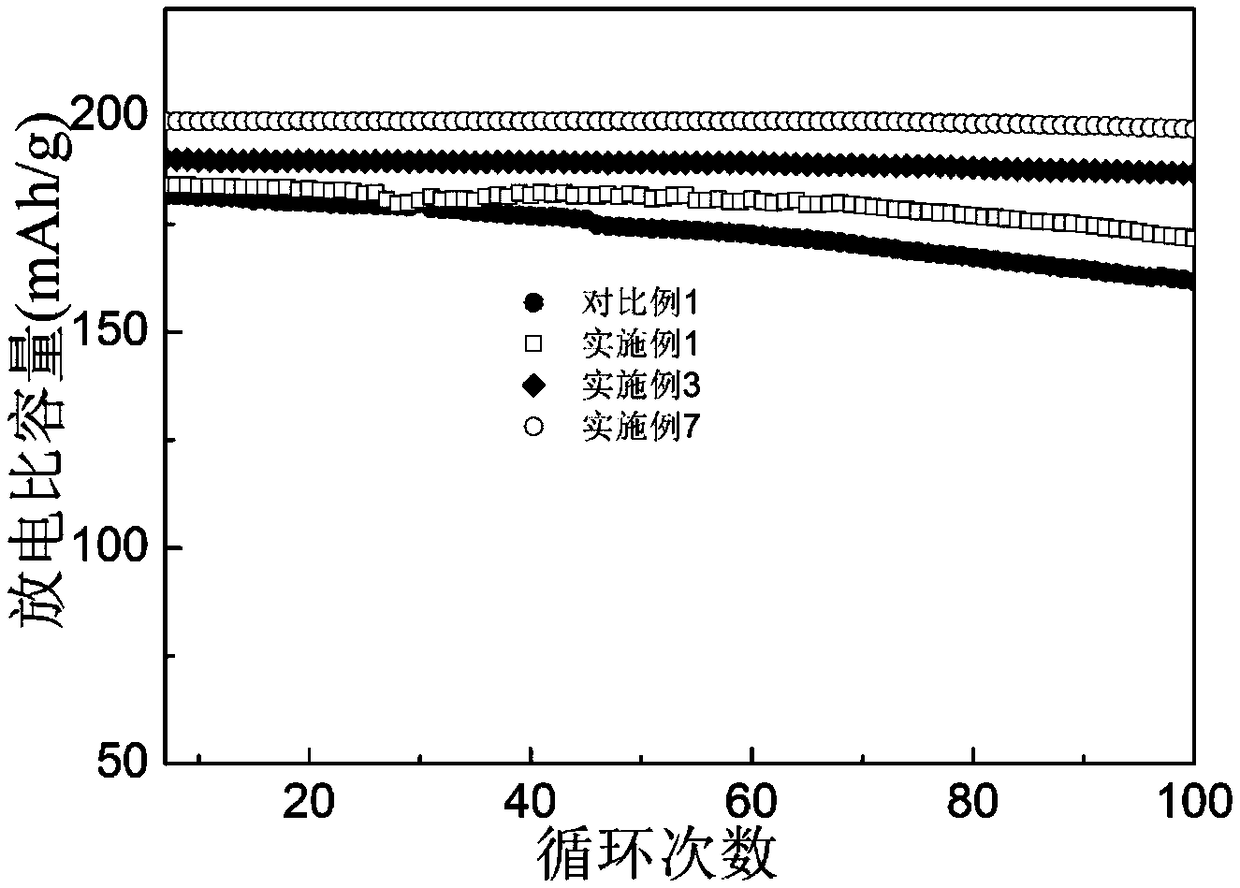

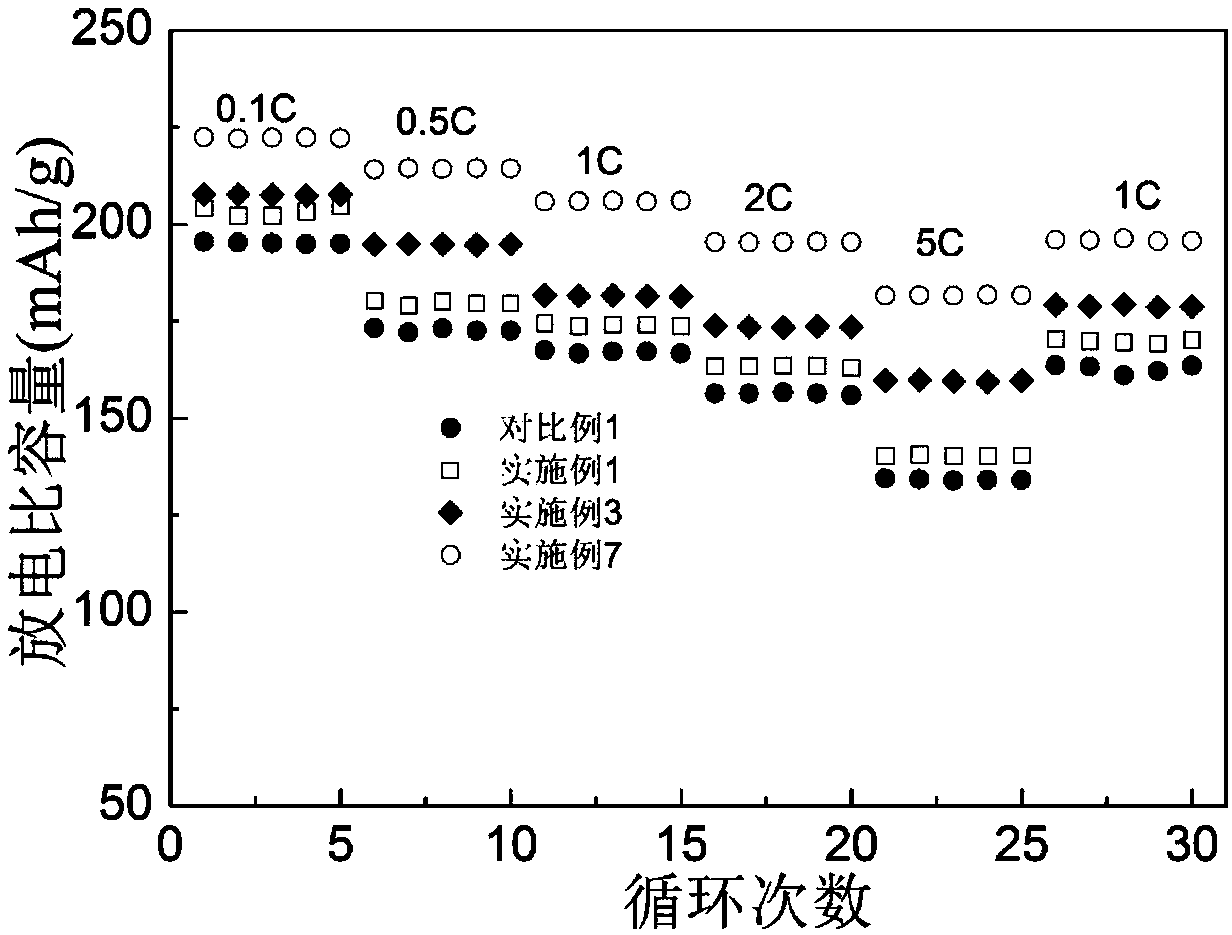

[0032] Use the above positive electrode, metal lithium as negative electrode, 1mol / L lithium hexaf...

Embodiment 1

[0039] Embodiment 1: the preparation of the positive electrode piece that contains the positive electrode material of weak acid additive

[0040] Weigh 9.97g LiNi 0.8 co 0.1 mn 0.1 o 2 and 0.03 g of diethyl malonate were ground and mixed to obtain additive-containing positive electrode material T1.

[0041] Weigh 8.5g of positive electrode material T1, 1g of Super-p conductive agent, 0.5g of polyvinylidene fluoride (PVdF) and disperse it with nitrogen methylpyrrolidone (NMP), stir for 6h, coat the slurry on aluminum foil, and heat it in an oven at 60°C Dry for 4 hours, and then dry in a vacuum oven at 120° C. for 12 hours to obtain positive electrode sheet 2#.

Embodiment 2

[0042] Embodiment 2: Preparation of the positive electrode sheet of the positive electrode material containing weak acid additive

[0043] Weigh 9.9g LiNi 0.8 co 0.1 mn 0.1 o 2 and 0.1 g of acetic acid were ground and mixed to obtain the additive-containing positive electrode material T2.

[0044] Weigh 8.5g of positive electrode material T2, 1g of Super-p conductive agent, 0.5g of polyvinylidene fluoride (PVdF) and disperse it with nitrogen methylpyrrolidone (NMP), stir for 6h, coat the slurry on aluminum foil, and heat it in an oven at 60°C Dry for 4 hours, and then dry in a vacuum oven at 120° C. for 12 hours to obtain positive electrode sheet 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com