Welding method of super duplex stainless steel 2507

A duplex stainless steel and welding method technology, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of occupational health injuries of welders, low effective utilization of materials, and large environmental pollution, and achieve obvious energy saving effects and reduce Generation of harmful fumes and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in combination with specific embodiments.

[0034] A welding method of super duplex stainless steel 2507, said method comprising:

[0035] (1) Using melting pole semi-automatic gas shielded welding GMAW;

[0036] (2) The welding material used for welding is solid welding wire;

[0037] (3) The wire feeding speed of the welding wire is 6-8m / min.

[0038] (4) The flow rate of the protective gas is 15-20L / min

[0039] (5) The shielding gas used for welding is a mixture of 75% argon and 25% helium;

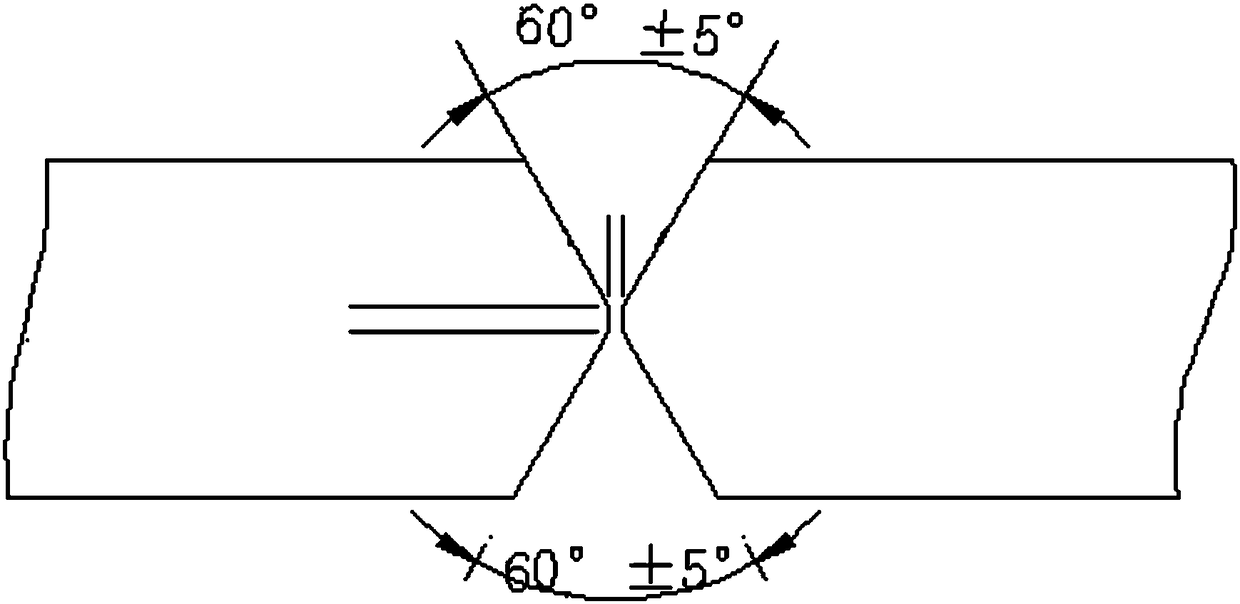

[0040] (6) if figure 1 As shown, the welding groove is ground into a double-sided "V" shape;

[0041] (7) Clean up the greasy dirt and moisture in the groove inside and both sides of the groove in method (6) within the range of 25mm;

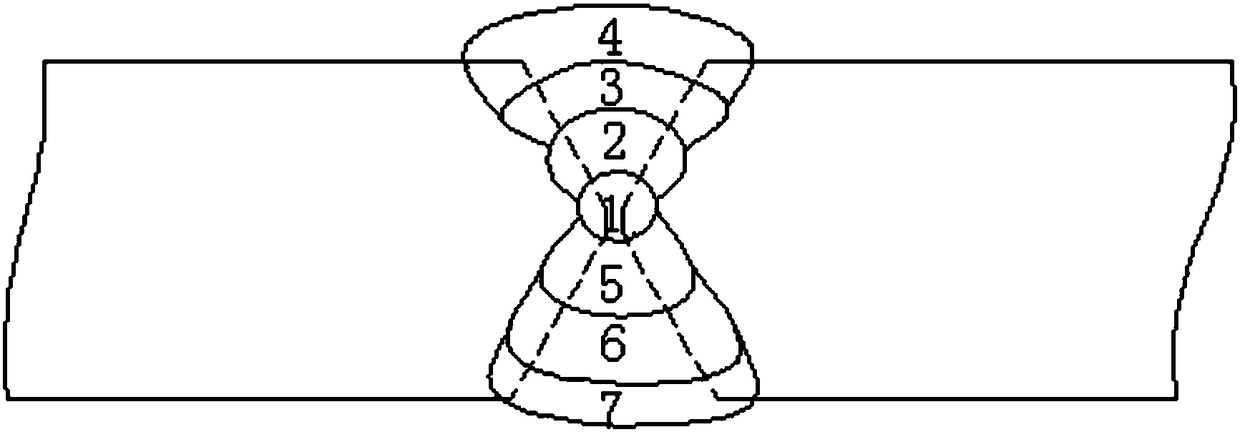

[0042] (8) if figure 2 As shown, the number of welding layers of the welding groove is from top to bottom 4, 3, 2, 1, 5, 6, 7 layers, and through such as Figure 5 The weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com