Preparation and application of a graphene/silicon composite thermal grease

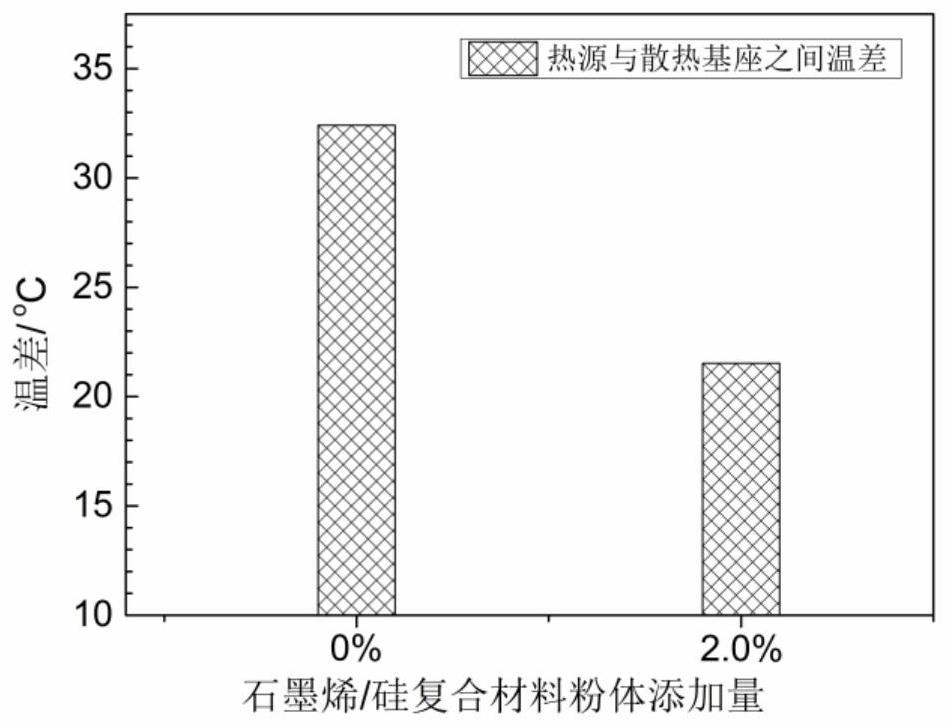

A technology of thermally conductive silicone grease and graphene, which is applied in the preparation of graphene/silicon composite thermally conductive silicone grease and the field of graphene/silicon composite thermally conductive silicone grease, and can solve problems such as thermally conductive resins that do not use silicon-based graphene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the present invention provides a kind of preparation method of modified graphene heat conduction silicone grease, comprises the following steps:

[0032] (1) Add 1 g of graphene powder into a mixed system of 500 mL of water and ethanol, and ultrasonically disperse it into a suspension.

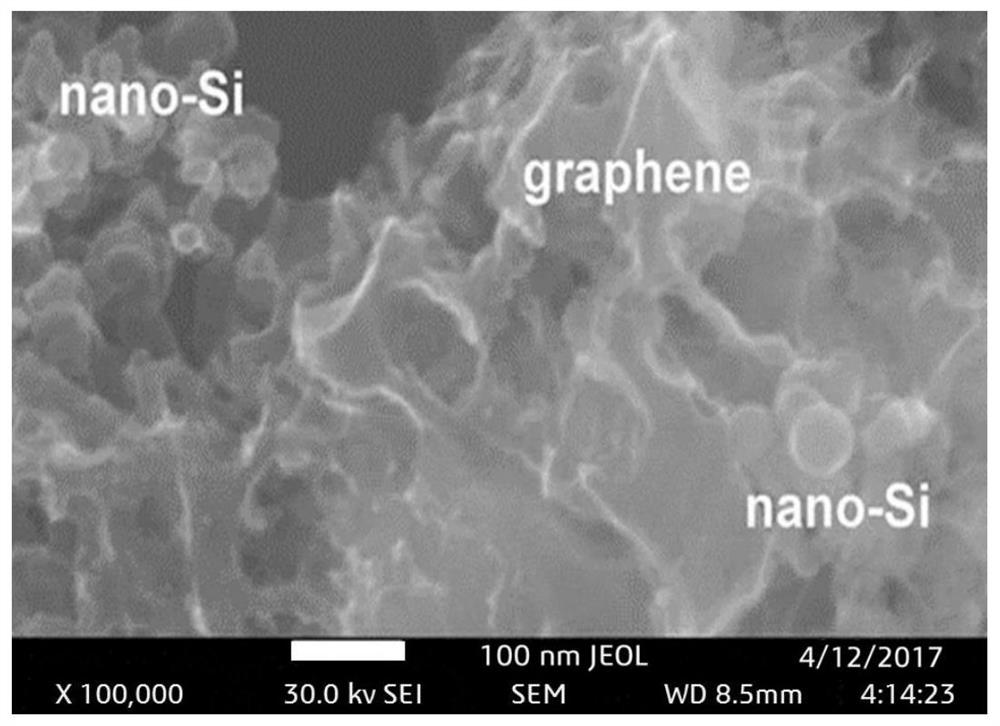

[0033] (2) Add 5g of nano-silicon particles after cleaning in the dispersion, after ultrasonic dispersion, mechanically stir for 12h at 55°C to obtain a graphene / silicon composite material dispersion, wherein graphene and nano-silicon particles are physically adsorbed way combined.

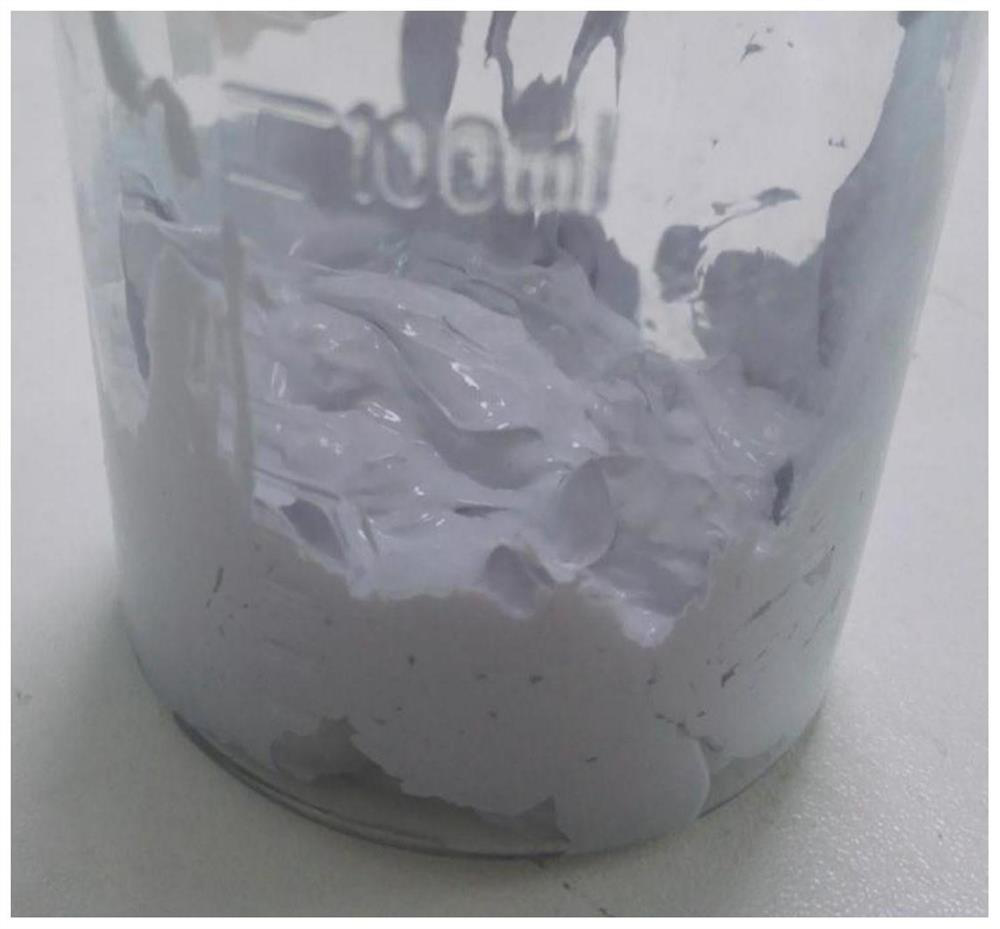

[0034] (3) Dry the prepared graphene / silicon composite material dispersion by spray drying to obtain graphene / silicon composite material powder.

[0035] (4) Place the graphene / silicon composite powder in a vacuum oven at 65°C and dry it in vacuum for 1 hour to remove residual moisture in the graphene / silicon composite powder and to remove the residual moisture from the graphene / silicon compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com