Electrolyte and preparation method as well as secondary lithium-sulfur battery using electrolyte

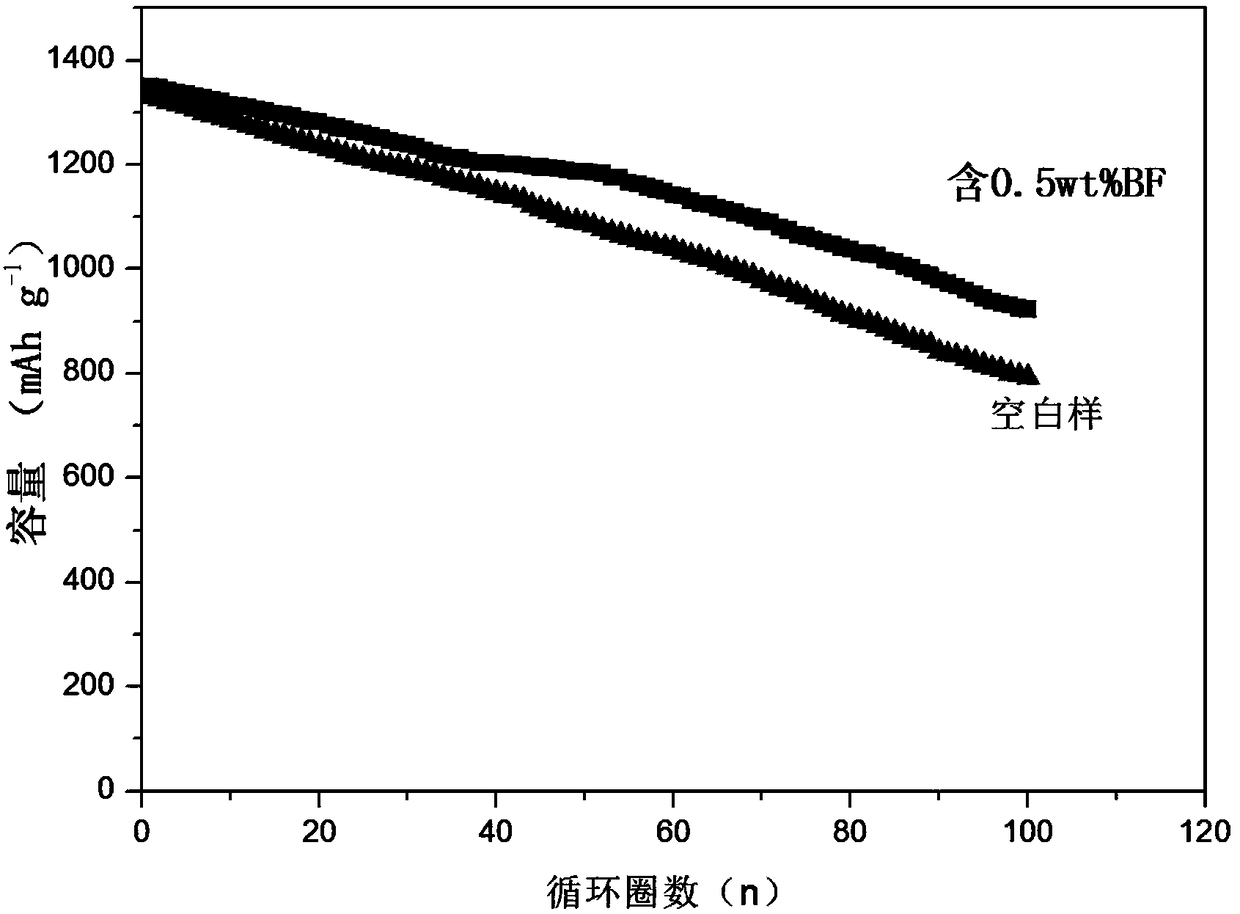

A lithium-sulfur battery and electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of less research and unsatisfactory effects, reduce corrosion, improve cycle stability and capacity retention, and inhibit The effect of capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

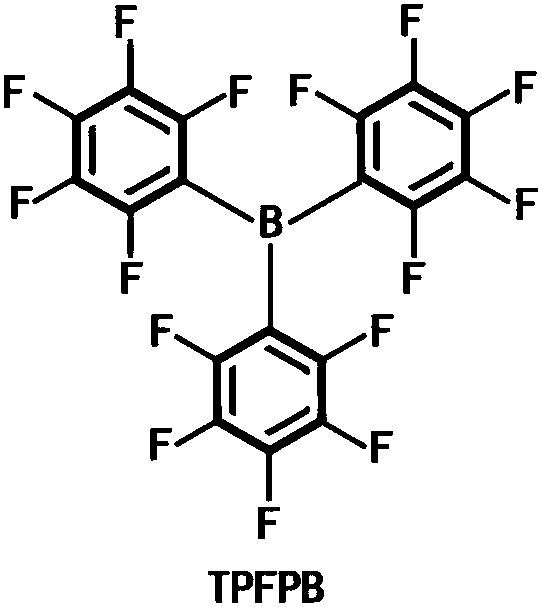

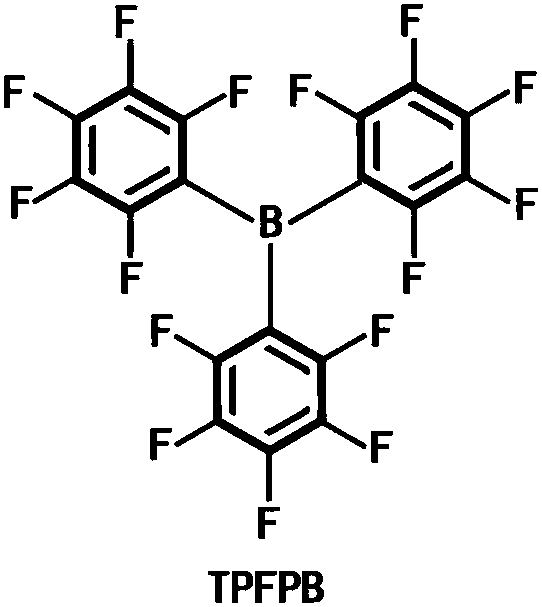

[0020] In the glove box, mix 1,3-dioxolane and ethylene glycol dimethyl ether uniformly at a volume ratio of 1:1, add lithium bistrifluoromethanesulfonimide to the mixed solvent, stir well, and prepare the concentration For 1mol / L electrolyte, add 1wt% lithium nitrate. Add the functional additive trifluoropentaphenylborane to the electrolyte to obtain a functional electrolyte, and the functional additives account for 0.1%, 0.5%, 1%, 2%, and 3% by mass of the total weight of the electrolyte, respectively. %.

Embodiment 2

[0022] Fluoroethylene carbonate, propylene carbonate and ethylene glycol diethyl ether were evenly mixed in a glove box at a volume ratio of 1:1:1, and LiN(FSO 2 ) 2 and LiN(CF 3 SO 2 ) 2 , and stir evenly to make an electrolyte solution with a concentration of 0.5mol / L. Add the functional additive trifluoropentaphenylborane to the electrolyte to obtain a functional electrolyte, and the functional additives account for 0.1%, 0.5%, 1%, 2%, and 3% by mass of the total weight of the electrolyte, respectively. %.

Embodiment 3

[0024] Mix ethylene carbonate and ethyl methyl carbonate uniformly at a volume ratio of 1:1 in the glove box, and add LiBC to the mixed solvent 2 o 4 f 2 , and stir evenly to make an electrolyte solution with a concentration of 5mol / L. Add the functional additive trifluoropentaphenylborane to the electrolyte to obtain a functional electrolyte, and the functional additives account for 0.1%, 0.5%, 1%, 2%, and 3% by mass of the total weight of the electrolyte, respectively. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com