Preparation method of high-activity hollow composite photocatalyst Ag/Au/AgCl

A technology of composite light and catalyst, applied in the field of catalysis, to achieve the effect of improved photocatalytic performance, easy operation and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

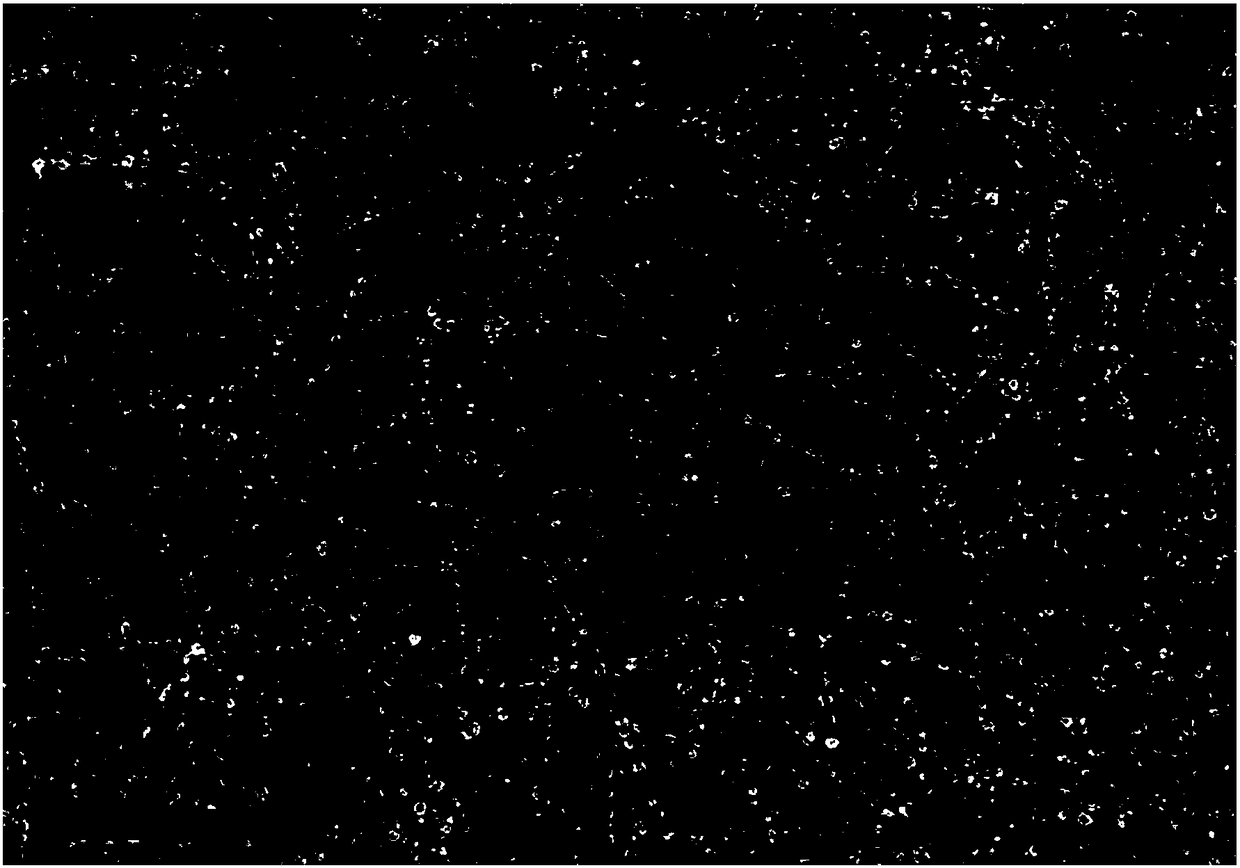

[0041] Step 1, preparation of Ag nanowires: weigh 0.1699gAgNO 3 Add the powder into 10mL of ethylene glycol, ultrasonically disperse and stir in a water bath at 30°C, then dissolve 0.1669g of polyvinylpyrrolidone (PVP, M W =10000, molar mass M=111g / mol) and 0.0019gCuCl 2 2H 2 O (PVP concentration is 0.15mol / L, CuCl 2 Concentration is 1mmol / L), after fully dissolved, mix AgNO 3 Solution and PVP solution, and put the mixed solution into a 50mL polytetrafluoroethylene liner reactor to react at 140°C for 3 hours; then centrifuge the completed solution to collect it, and wash it three times alternately with ethanol and water above, and then place it in a vacuum oven at 50°C for 10 hours to dry.

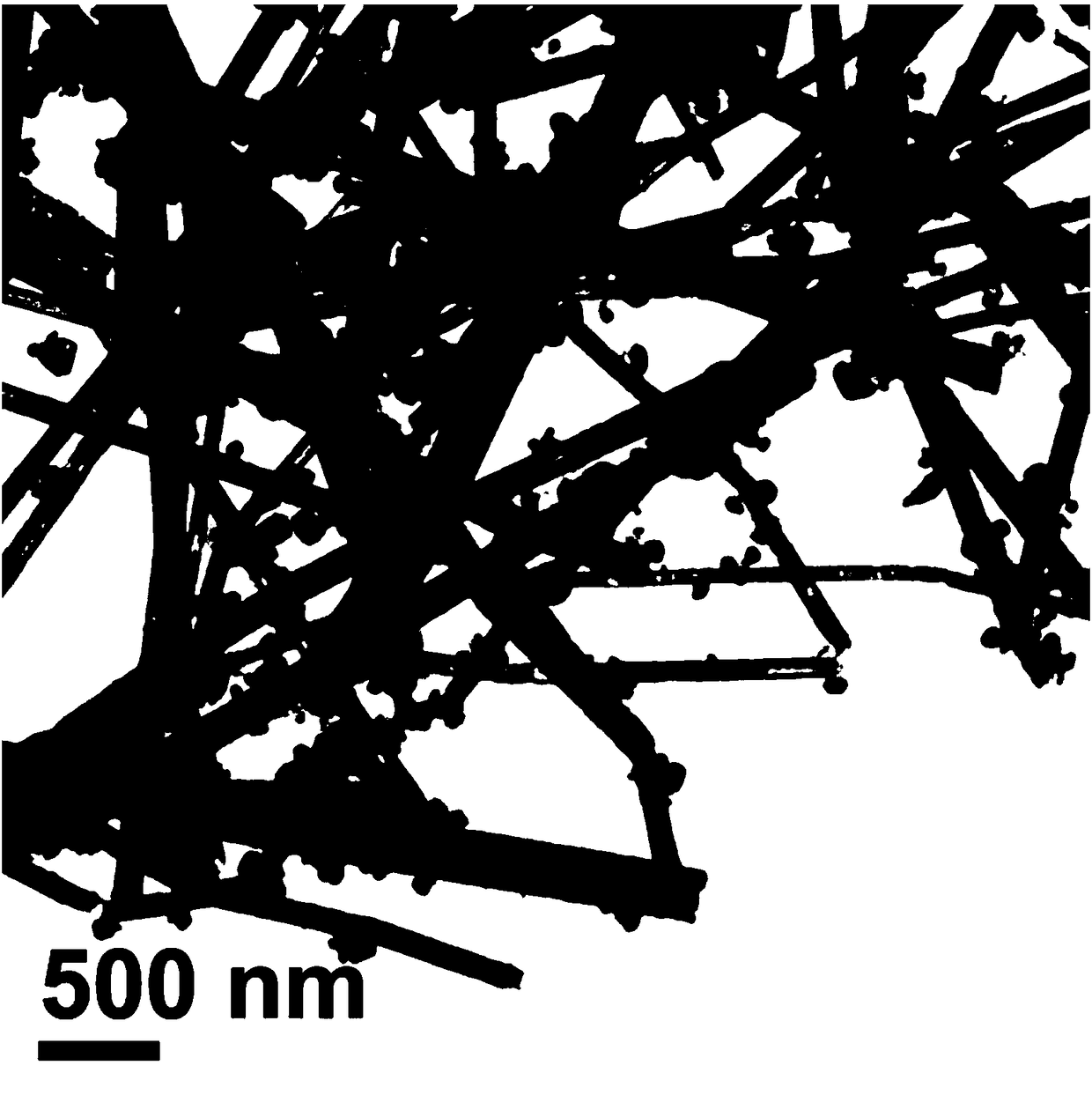

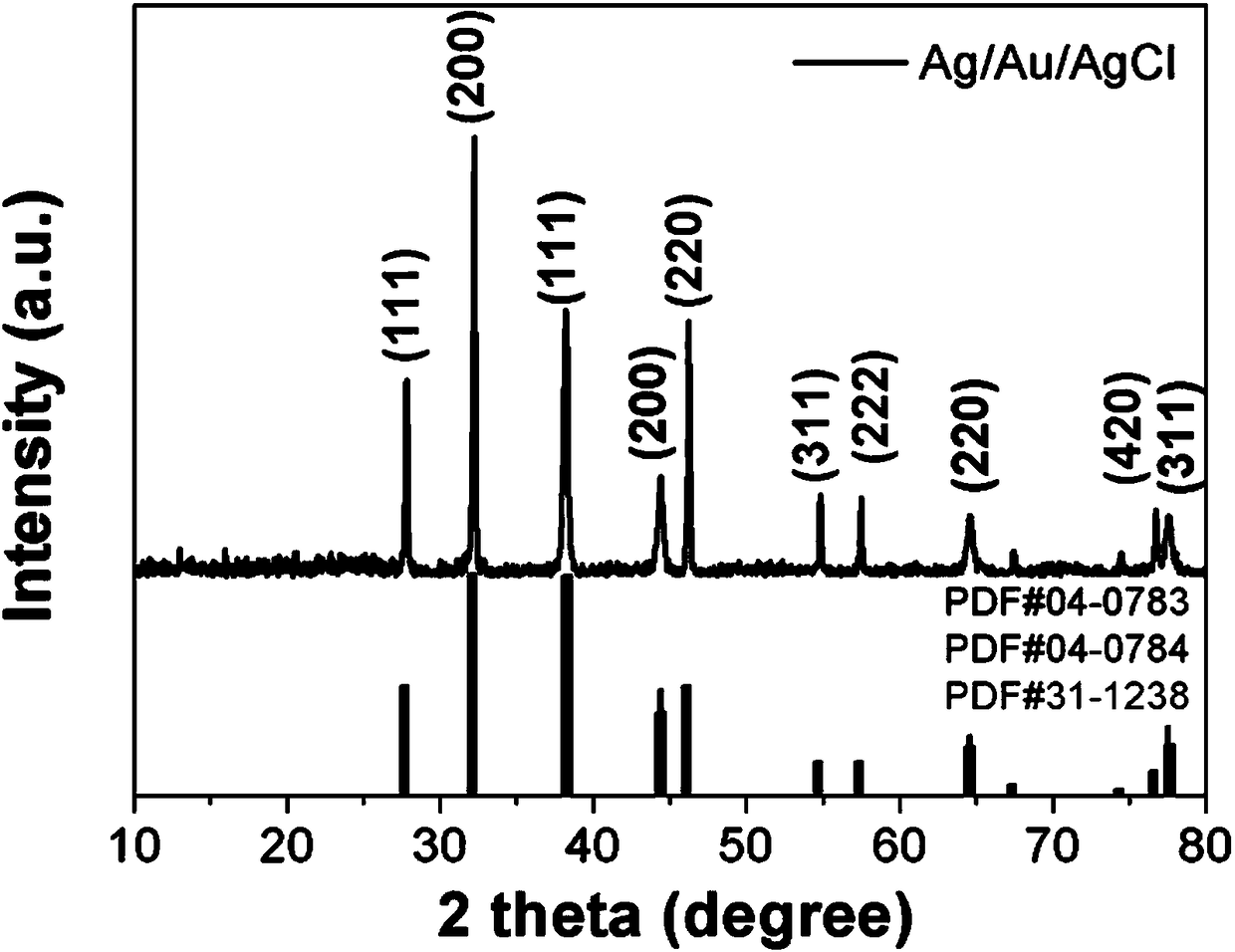

[0042] Step 2, the preparation of Ag / Au / AgCl series hollow composite catalyst: take 15mg by weighing the Ag nanowire that step 1 makes and add in 10mL dehydrated alcohol, then add 20mgPVP (M W =58000) powder, after stirring at 30°C to fully dissolve, add 0.5mL HAuCl dropwise 4 soluti...

Embodiment 2

[0049] Step 1, the preparation of Ag nanowires, the preparation method is the same as in Example 1;

[0050] Step 2, preparation of Ag / Au / AgCl string-shaped hollow composite photocatalyst: Weigh 15 mg of Ag nanowires prepared in step 1 and add them to 10 mL of absolute ethanol, then add 20 mg of PVP (Mw=58000) powder, at 30 ° C After stirring fully to dissolve, add 1.0mL HAuCl dropwise 4 solution (0.2mM), the solution continued to react at 30°C for 10 hours; the completed solution was centrifuged, washed alternately with ethanol and water for more than 3 times, and then the obtained precipitate was dried in a vacuum oven at 50°C for 10 hours, Obtain Ag / Au / AgCl series hollow composite photocatalyst. In the obtained product, the molar ratio of Ag, Au and AgCl is 8:2:6.

[0051] Under the same photocatalytic conditions as in the photocatalytic experiment of Example 1, the photocatalyst prepared in Example 2 can degrade 93.6% of AO7 within 3 minutes.

Embodiment 3

[0053] Step 1, the preparation of Ag nanowires, the preparation method is the same as in Example 1;

[0054] Step 2, the preparation of Ag / Au / AgCl string hollow composite photocatalyst: take 15mg by weighing the Ag nano wire that makes by step 1 and add in 10mL dehydrated alcohol, then add 20mgPVP (M W =58000) powder, after stirring at 30°C to fully dissolve, add 1.5mL HAuCl dropwise 4 solution (0.2mM), the solution continued to react at 30°C for 10 hours; the completed solution was centrifuged, washed alternately with ethanol and water for more than 3 times, and then the obtained precipitate was dried in a vacuum oven at 50°C for 10 hours, Obtain Ag / Au / AgCl series hollow composite photocatalyst. In the obtained product, the molar ratio of Ag, Au and AgCl is 5:3:9.

[0055] Under the same photocatalytic conditions as in the photocatalytic experiment of Example 1, the photocatalyst prepared in Example 3 can degrade 92.9% of AO7 within 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com