Multi-effect sludge drying chamber

A sludge and drying technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low energy utilization rate, achieve good technical effects, improve utilization rate, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

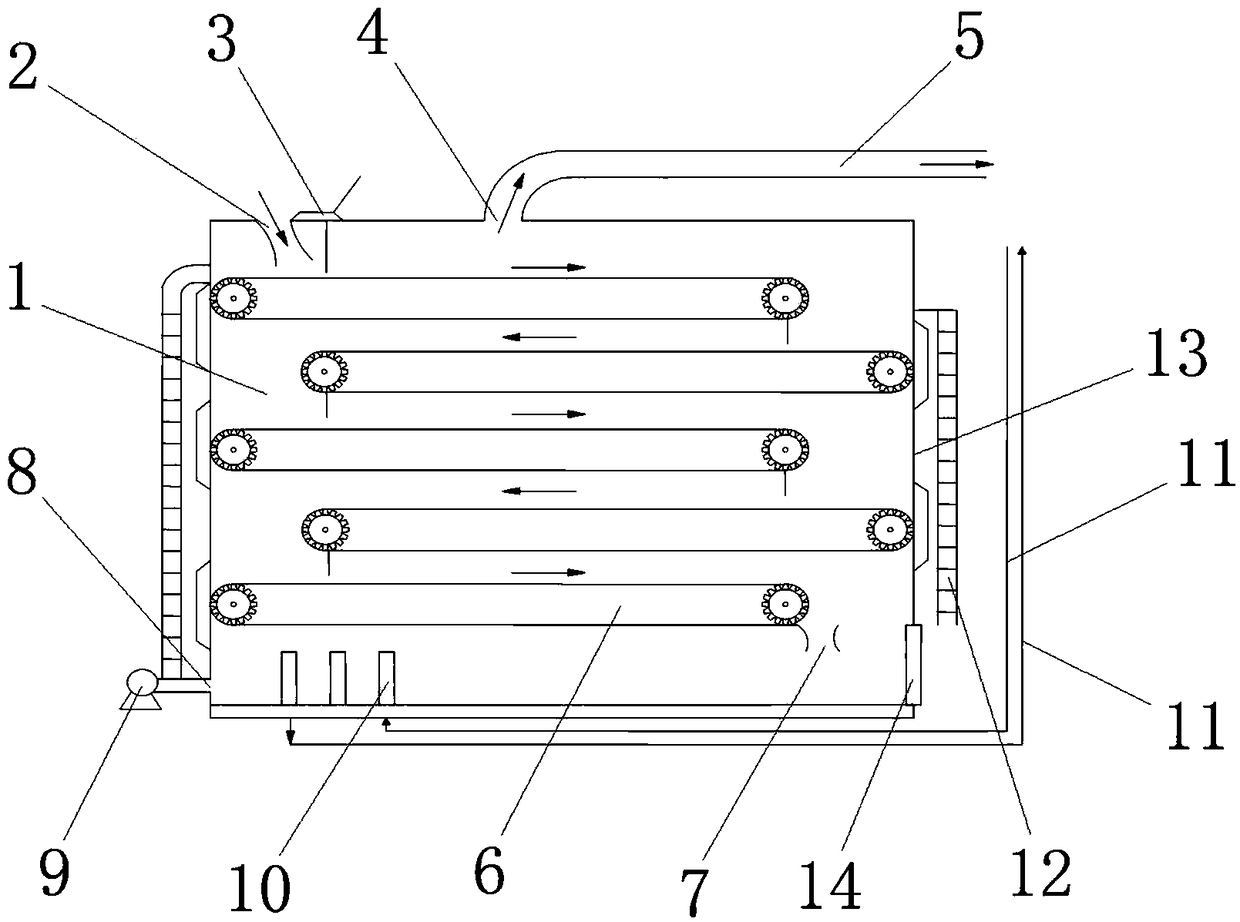

[0023] Multi-effect drying room for sludge, such as figure 1 As shown, it includes bin body 1, feeding port 2, cover plate 3, exhaust port 4, exhaust gas pipeline 5, conveyor belt 6, discharge port 7, air inlet 8, fan 9, heat exchanger 10, condensate pipeline 11 , Observation ladder 12, inspection port 13, bin door 14, wherein the feeding port 2 is located at the top of the bin body 1, the feeding port 2 is connected with a cover 3, and the top of the bin body 1 is also provided with an exhaust port 4 An exhaust gas pipeline 5 is connected to the exhaust port 4, a number of conveyor belts 6 staggered from top to bottom are arranged inside the bin body 1, and the discharge port 7 is located at the edge of the lowermost conveyor belt 6; One side of the lower end of the body 1 has an air inlet 8, and the other side of the lower end of the warehouse body 1 is connected with a warehouse door 14. The air inlet 8 is provided with a fan 9 which is located outside the warehouse body 1. ...

Embodiment 2

[0027] Multi-effect sludge drying room, including bin body 1, feeding port 2, cover plate 3, exhaust port 4, exhaust gas pipeline 5, conveyor belt 6, discharge port 7, air inlet 8, fan 9, heat exchanger 10 , Condensate pipeline 11, observation ladder 12, inspection port 13, warehouse door 14, wherein the feeding port 2 is located at the top of the silo body 1, the feeding port 2 is connected with a cover 3, and the top of the silo body 1 is also provided There is an exhaust port 4, and an exhaust gas pipeline 5 is connected to the exhaust port 4. A number of conveyor belts 6 arranged alternately are arranged from top to bottom inside the bin body 1, and the discharge port 7 is located at the lowermost conveyor belt 6 One side of the lower end of the warehouse body 1 has an air inlet 8, the other side of the lower end of the warehouse body 1 is connected to a warehouse door 14, the air inlet 8 is provided with a fan 9, the fan 9 is located outside the warehouse body 1 , The blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com