Production method of edible phospholipid and edible phospholipid obtained through production

A production method and phospholipid technology, applied in the field of oil processing, can solve the problems of increased phospholipid peroxide value, limited product application range, difficult mass production, etc., and achieves low peroxide value, short heating time, and reduced thermal decomposition. the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

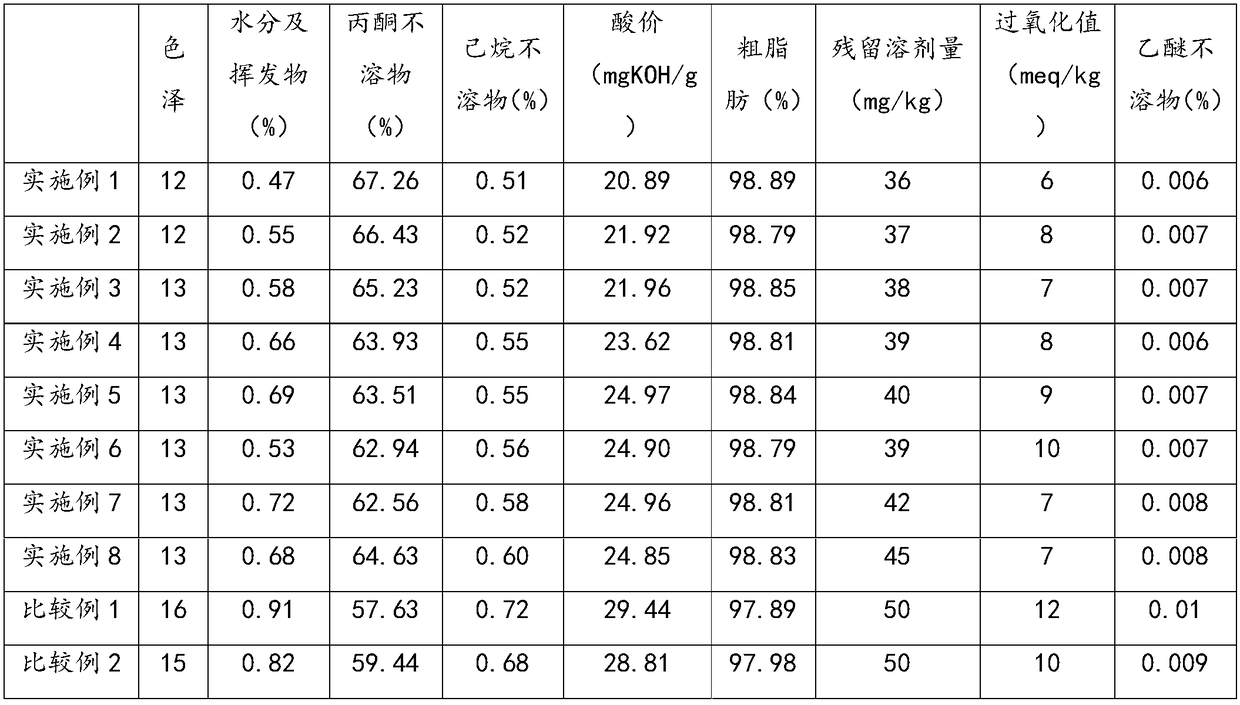

Examples

Embodiment 1

[0037] The production method of edible phospholipid described in the present embodiment comprises the steps:

[0038] (A) Feed-grade soybean lecithin and n-hexane are mixed in a mixing tank at a mass ratio of 1:3 to form a uniform mixture, and the mixture is filtered through a 60-mesh filter to remove solid impurities, and then enters the membrane filtration system. After being filtered by a 0.1μm membrane, the phospholipid molecules enter the filtrate through the membrane, while the macromolecular substances such as proteins, polysaccharides, bacteria and the remaining very small amount of solid impurities in the solution are intercepted by the membrane, and the filtrate is purified; with the filtration The solution is concentrated, the concentration is increased, and n-hexane is added regularly to dilute to ensure the normal progress of the filtration; the above-mentioned filtration steps are carried out in a cycle, and after 8-10 hours of circulating filtration, most of the ...

Embodiment 2

[0043] The production method of edible phospholipid described in the present embodiment comprises the steps:

[0044] (A) Feed-grade phospholipids and n-hexane are mixed in a mixing tank at a mass ratio of 1:2 to form a uniform mixture, and the mixture is filtered through a 60-mesh filter to remove solid impurities, and then enters the membrane filtration system. After 0.1μm membrane filtration, phospholipid molecules enter the filtrate through the membrane, while the protein, polysaccharide, bacteria and other macromolecular substances in the solution and the remaining very small amount of solid impurities are intercepted by the membrane, and the filtrate is purified; , the solution is concentrated, the concentration is increased, regular addition of n-hexane to dilute to ensure the normal progress of the filtration; the above-mentioned filtration steps are carried out in a cycle, and after 8-10 hours of circulating filtration, most of the phospholipid molecules enter the filt...

Embodiment 3

[0049] This embodiment refers to the production method described in Example 1, the main difference is that in the step (A), the mass ratio of feed grade phospholipid to n-hexane is 1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com