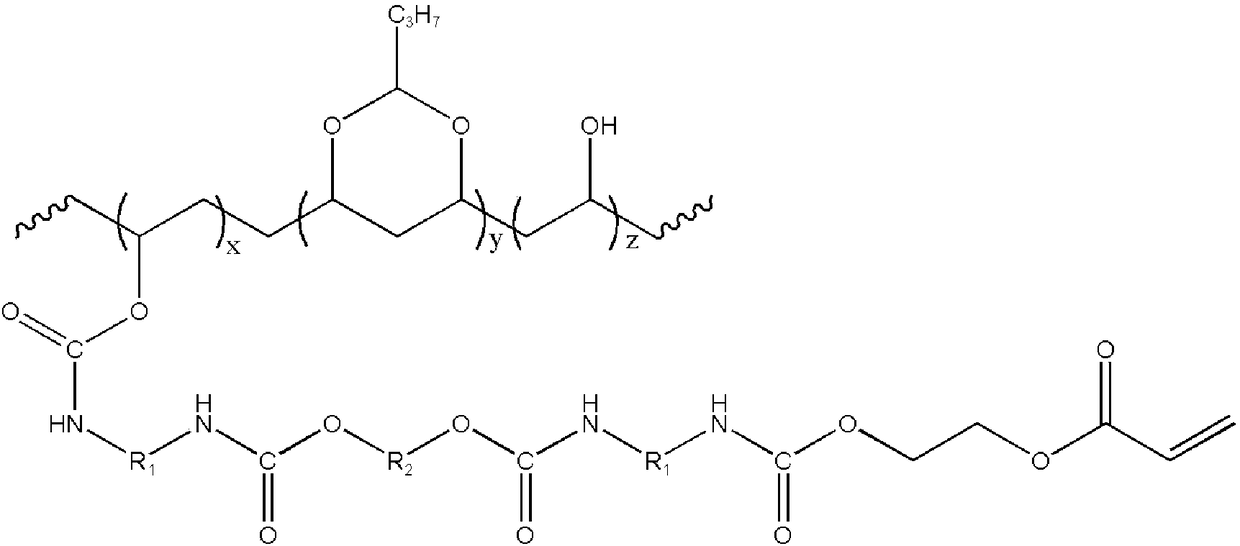

Polyvinyl butyral polyurethane acrylate, synthesis method and application thereof

A technology of urethane acrylate and polyvinyl butyral, which is applied in the field of polyvinyl butyral urethane acrylate and its synthesis, can solve problems such as limiting the application of acrylic resin, and achieve excellent mechanical properties, excellent bonding properties, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

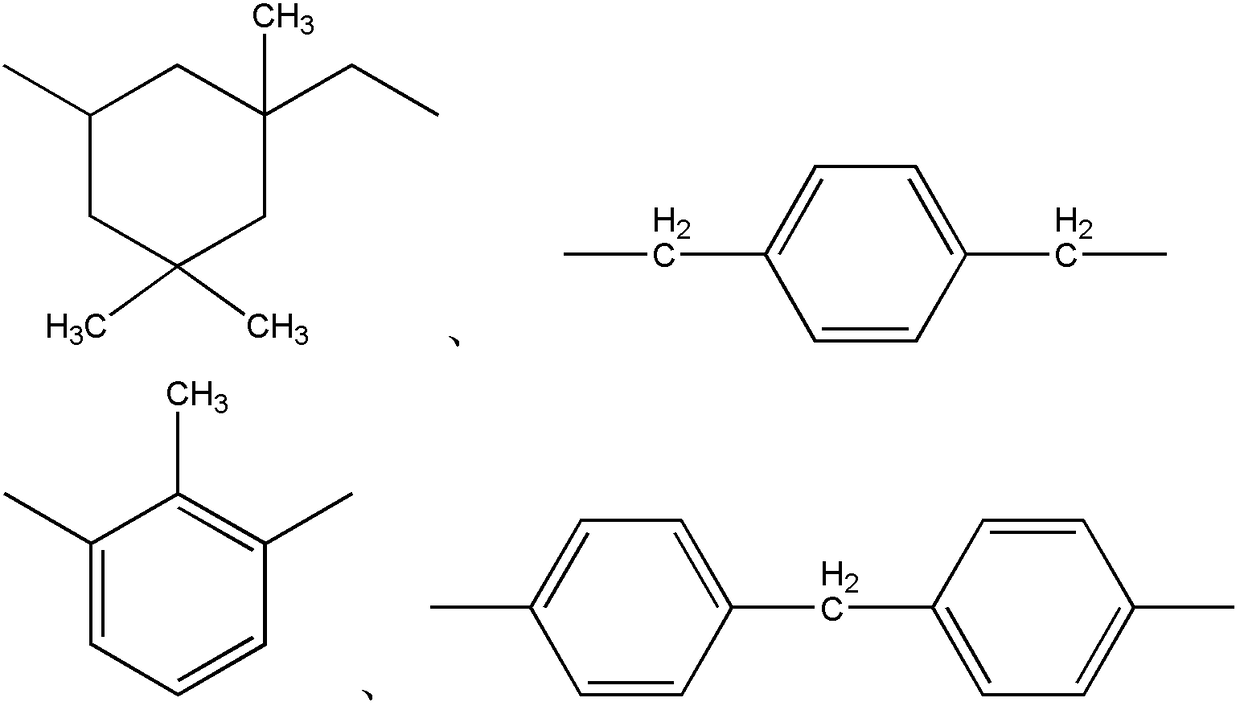

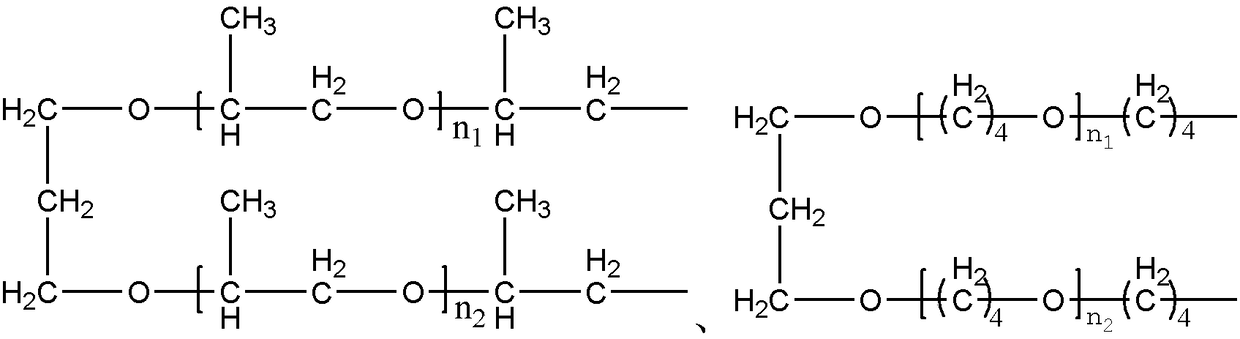

[0047]Dissolve 44.40g of isophorone diisocyanate in chloroform, add 0.45g of catalyst dibutyltin dilaurate, stir evenly, and then add dropwise to the mixed solution of isophorone diisocyanate and catalyst at 40°C 40.00g of dihydroxy polyoxypropylene ether (204, hydroxyl value 280±20mgKOH / g), heated to 50°C for 2h to form polyurethane prepolymer; add 0.03g of polymerization inhibitor to 28.06g of hydroxyethyl acrylate (HEA) Mix p-hydroxyanisole evenly, then drop the mixed solution of HEA and polymerization inhibitor into the above polyurethane prepolymer at 40°C, raise the temperature to 50°C and react for 3h to form polyurethane acrylate prepolymer; mix 8.80 1g of polyvinyl butyral (PVB) was dissolved in chloroform, and 0.09g of catalyst dibutyltin dilaurate was added, stirred evenly, and then 0.44g of the above polyurethane was added dropwise to the mixed solution of PVB and catalyst at 40°C The acrylate prepolymer is heated to 50°C for 3 hours to react to form polyvinyl buty...

Embodiment 2

[0049] Dissolve 44.40g of isophorone diisocyanate in 1,4-dioxane, add 1.11g of catalyst dibutyltin dilaurate, stir evenly, and then add isophorone diisocyanate and catalyst at 50°C Add 112.36g of dihydroxy polyoxypropylene ether (210, hydroxyl value 100±10mgKOH / g) dropwise to the mixed solution, raise the temperature to 60°C for 3 hours to form a polyurethane prepolymer; add to 28.06g of hydroxyethyl acrylate (HEA) 0.03g polymerization inhibitor p-hydroxyanisole, mix well, then add the mixed solution of HEA and polymerization inhibitor dropwise to the above polyurethane prepolymer at 50°C, raise the temperature to 60°C and react for 4h to form polyurethane acrylate prepolymer Polymer; Dissolve 8.80g polyvinyl butyral (PVB) in chloroform, add 0.44g catalyst dibutyltin dilaurate, stir evenly, then drop into the mixed solution of PVB and catalyst at 50°C Add 1.76g of the above urethane acrylate prepolymer, heat up to 60°C and react for 4 hours to form polyvinyl butyral urethane a...

Embodiment 3

[0051] Dissolve 69.66g of toluene diisocyanate in N,N-dimethylformamide, add 3.48g of catalyst dibutyltin dilaurate, stir well, then add dropwise to the mixed solution of toluene diisocyanate and catalyst at 45°C 200.36g of dihydroxypolytetrahydrofuran oxypropyl ether (220, hydroxyl value 56±4mgKOH / g), heated to 55°C for 4 hours to form a polyurethane prepolymer; add 0.28g of inhibitor to 28.06g of hydroxyethyl acrylate (HEA) agent p-hydroxyanisole, mix evenly, then drop the mixed solution of HEA and polymerization inhibitor into the above polyurethane prepolymer at 45°C, raise the temperature to 50°C and react for 4h to form polyurethane acrylate prepolymer; Dissolve 8.80g of polyvinyl butyral (PVB) in chloroform, add 0.22g of catalyst dibutyltin dilaurate, stir evenly, then add dropwise 3.52g of the above-mentioned The urethane acrylate prepolymer is heated to 70°C for 6 hours to form polyvinyl butyral urethane acrylate, that is, photopolymerizable urethane acrylate containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com