Method for preparing recyclable epoxy resin by utilizing ontology click chemistry reaction

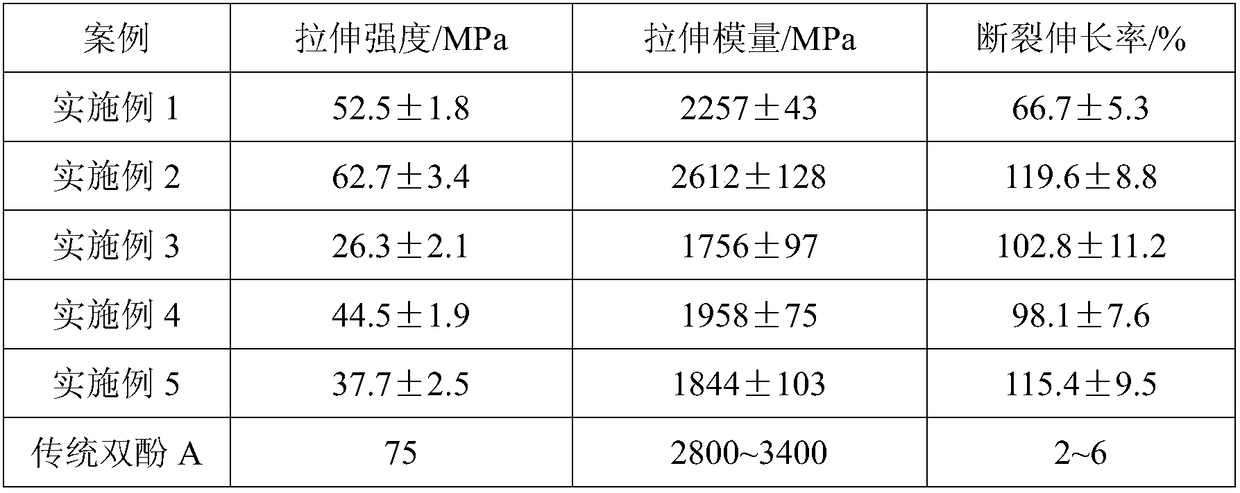

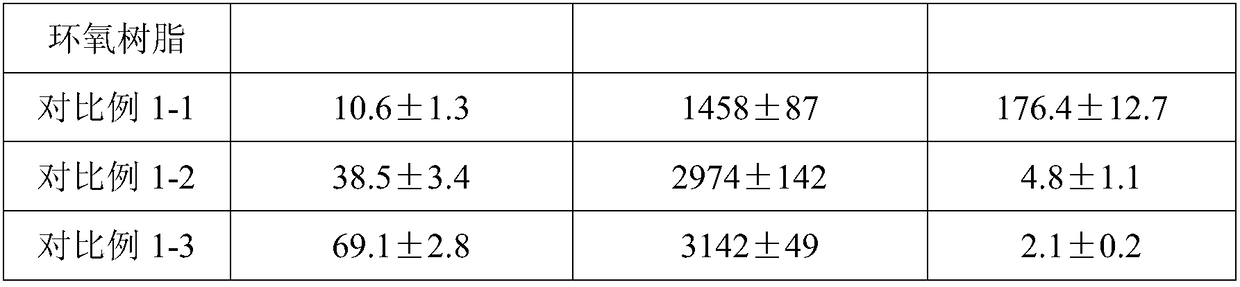

A click chemical reaction and epoxy resin technology, applied in the field of thermoplastic epoxy resin and its preparation, can solve the problems of slow reaction rate of amine and epoxy, reaction conversion rate cannot reach 100%, harsh reaction conditions, etc., and the method is simple and convenient. , Superior mechanical properties, toughness enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of preparation method of reusable epoxy resin, polyfunctional epoxy resin selects novolac epoxy resin, tertiary amine catalyst selects N,N-dimethylbenzylamine, and carries out the following steps successively:

[0030] 1) In a constant temperature oil bath at 20°C, add 40g of novolac epoxy resin and 16g of furfuryl mercaptan into a 100ml three-neck round bottom flask, and mix well by mechanical stirring; then add 1g of N,N-dimethylbenzyl The amine was placed in a nitrogen protective atmosphere and reacted for 3 hours to obtain an intermediate whose terminal group was a furan functional group, and the grafting rate reached 99.9%.

[0031] 2) Under the protection of nitrogen, the intermediate obtained by the reaction and 45g of N-N'-(4,4-methylenediphenyl)bismaleimide were stirred evenly in a constant temperature oil bath at 160°C, Fully react for 0.1 hour, pour into a polytetrafluoroethylene mold placed in an oven, and carry out crosslinking reaction...

Embodiment 2

[0032] Embodiment 2, a kind of preparation method of reusable epoxy resin, polyfunctional epoxy resin selects triglycidyl p-aminophenol, three (4-hydroxyphenyl) methane triglycidyl ether and 2,2 ', 2",2"'-[1,2-bis-dimethylene tetrakis(4,1-phenylene methylene oxide)]tetraoxirane mixture, bis(2-dimethyl Aminoethyl) ether, the steps are as follows:

[0033] 1) In a constant temperature oil bath at 100°C, add 22g of triglycidyl p-aminophenol, 10g of tris(4-hydroxyphenyl)methane triglycidyl ether and 38g of 2,2',2",2"' Add -[1,2-bidimethylene tetrakis(4,1-phenylene methylene oxide)]tetraoxirane and 33g furfuryl mercaptan into a 150ml three-neck round bottom flask, and mix well by mechanical stirring . Then 2.1 g of bis(2-dimethylaminoethyl) ether was added, placed in a nitrogen atmosphere, and reacted for 0.1 hour to obtain an intermediate whose terminal group was a furan functional group, and the grafting rate reached 99.7%.

[0034] 2) Under the protection of nitrogen, the int...

Embodiment 3

[0035] Embodiment 3, a kind of preparation method of reusable epoxy resin, multifunctional epoxy resin selects 1,1,1-three (4-hydroxyphenyl) ethyl triglycidyl ether and 4,4'-diamino The mixture of diphenylmethane epoxy resin, tertiary amine catalyst selects triethylamine for use, and step is as follows:

[0036] 1), in a constant temperature oil bath at 40°C, mix 22g of 1,1,1-tris(4-hydroxyphenyl)ethyl triglycidyl ether and 23g of 4,4'-diaminodiphenylmethane epoxy resin with 40g Furfuryl mercaptan was added into a 150ml three-necked round-bottomed flask, and mixed evenly by mechanical stirring. Then 2 g of triethylamine was added, placed in a nitrogen atmosphere, and reacted for 2 hours to obtain an intermediate whose terminal group was a furan functional group, and the grafting rate reached 99.8%.

[0037] 2), under the protection of nitrogen, the intermediate obtained by the reaction and 42g of N-N-(4-methyl-1,3-phenylene)bismaleimide were stirred evenly in a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com