Infrared-absorbing coating liquid, infrared-absorbing glass, and manufacturing method thereof

A manufacturing method, infrared technology, applied in radiation-absorbing coatings, coatings, etc., can solve the problems of poor aging resistance and wear resistance, low hardness, reduced hardness and friction resistance, and achieve high temperature resistance and excellent durability , high hardness, the effect of improving high temperature resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

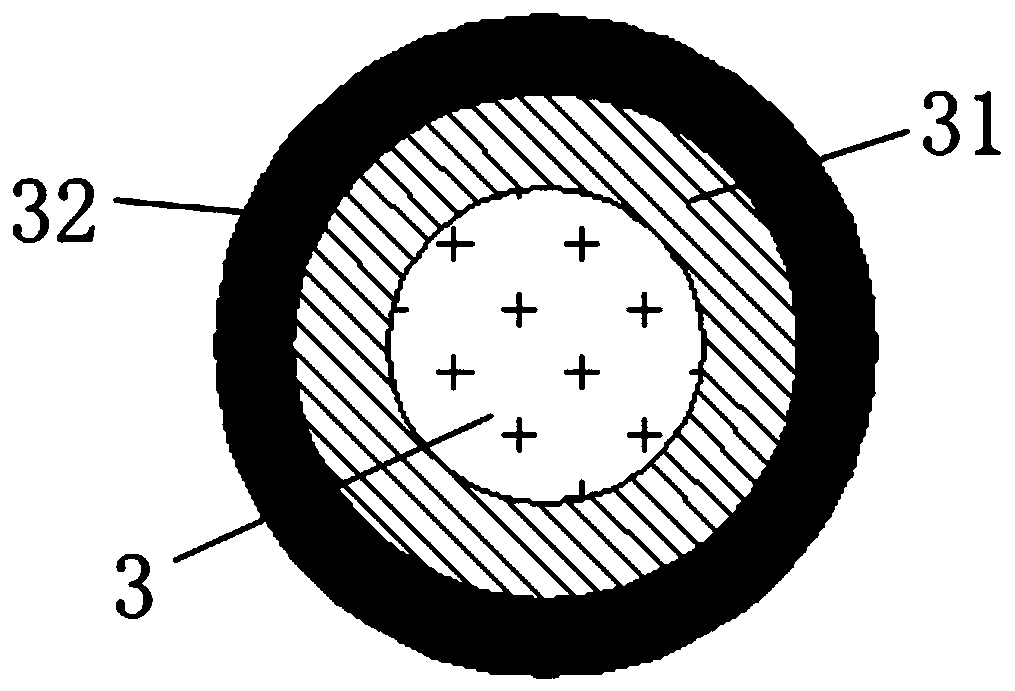

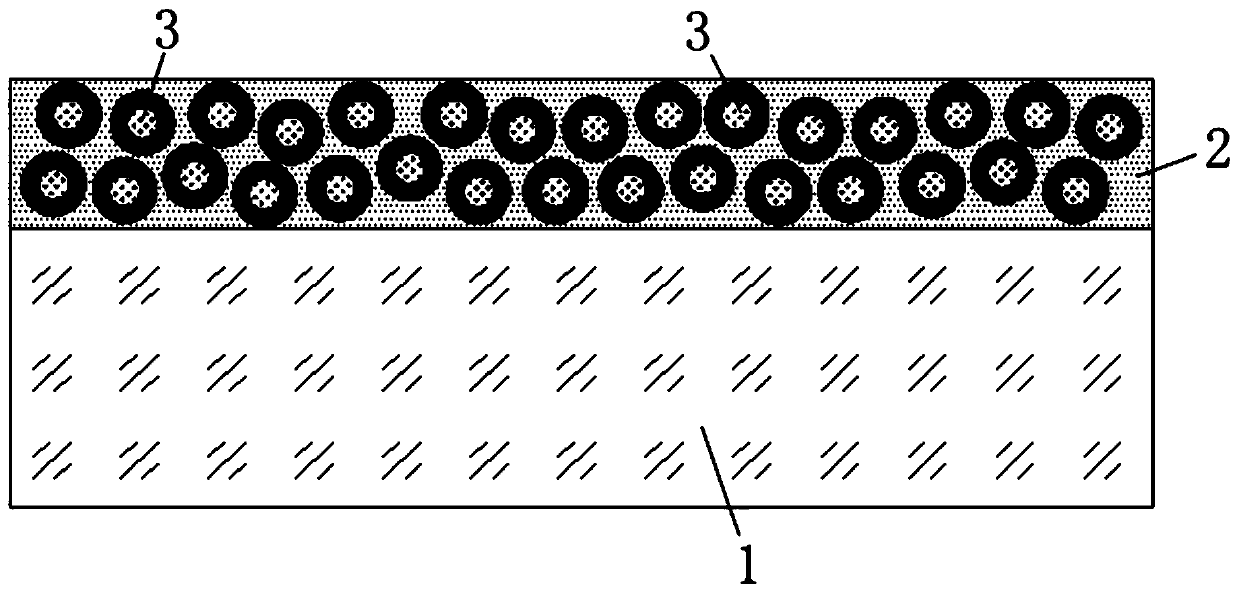

[0083] Weigh 50g of Cs0.33WO3 aqueous dispersion with a solid content of 30% and 10g of KH560, add ethanol and isopropanol, and make it uniformly mixed by ultrasonic dispersion and stirring to obtain mixed solution A1; weigh 60g of ethyl orthosilicate and 20g KH560, and obtain mixed solution B1 by ultrasonic dispersion and stirring; weigh 25g mixed solution A1 and 6g mixed solution B1, and obtain mixed solution C1 by ultrasonic dispersion and stirring; add deionized water and catalyst to mixed solution C1, and pass Ultrasonic dispersion and stirring, while hydrolysis and condensation reactions were carried out, CsxWO3 (cesium tungsten bronze) nanoparticles were initially wrapped in situ to obtain mixed solution D1; 14g mixed solution B1 and deionized water were added to mixed solution D1 and catalyst, continue to wrap the nanoparticles in the mixed solution D1 in situ to obtain the mixed solution E1; add 1 g of trimethyl borate to the mixed solution E1, and mix it evenly by sti...

Embodiment 2

[0086] A thickness of 3.2mm is prepared, and the float glass (FUYAO 3.2C) whose size is 150mm×150mm is used as a glass substrate. The visible light transmittance of the glass substrate is 89.84%, and the infrared transmittance is 81.84%; Coating solution F1 is evenly coated on the surface of the substrate, and dried at 200°C for 1 hour after surface drying, so as to obtain an infrared-absorbing glass with an infrared-absorbing coating; the hardness measured by the pencil hardness test method is 9H, The adhesion force measured by using a hundred grid knife is 0 grade, and the optical properties are listed in Table 1.

Embodiment 3

[0088] A thickness of 3.5mm is prepared, and a float green glass (FUYAO 3.5G) with a size of 150mm×150mm is used as a glass substrate. The visible light transmittance of the glass substrate is 81.46%, and the infrared transmittance is 43.46%; Coating solution F1 is evenly coated on the surface of the substrate, and dried at 200°C for 1 hour after surface drying, so as to obtain an infrared-absorbing glass with an infrared-absorbing coating; the hardness measured by the pencil hardness test method is 9H, The adhesion force measured by using a hundred grid knife is 0 grade, and the optical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com