New water-based environmental-protection material for replacing PET matt membrane and preparation method thereof

A new material, water-based technology, applied in the field of printing ink, can solve the problems of poor matte effect, poor environmental performance, influence, etc., and achieve the effects of easy large-scale promotion, excellent advection, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

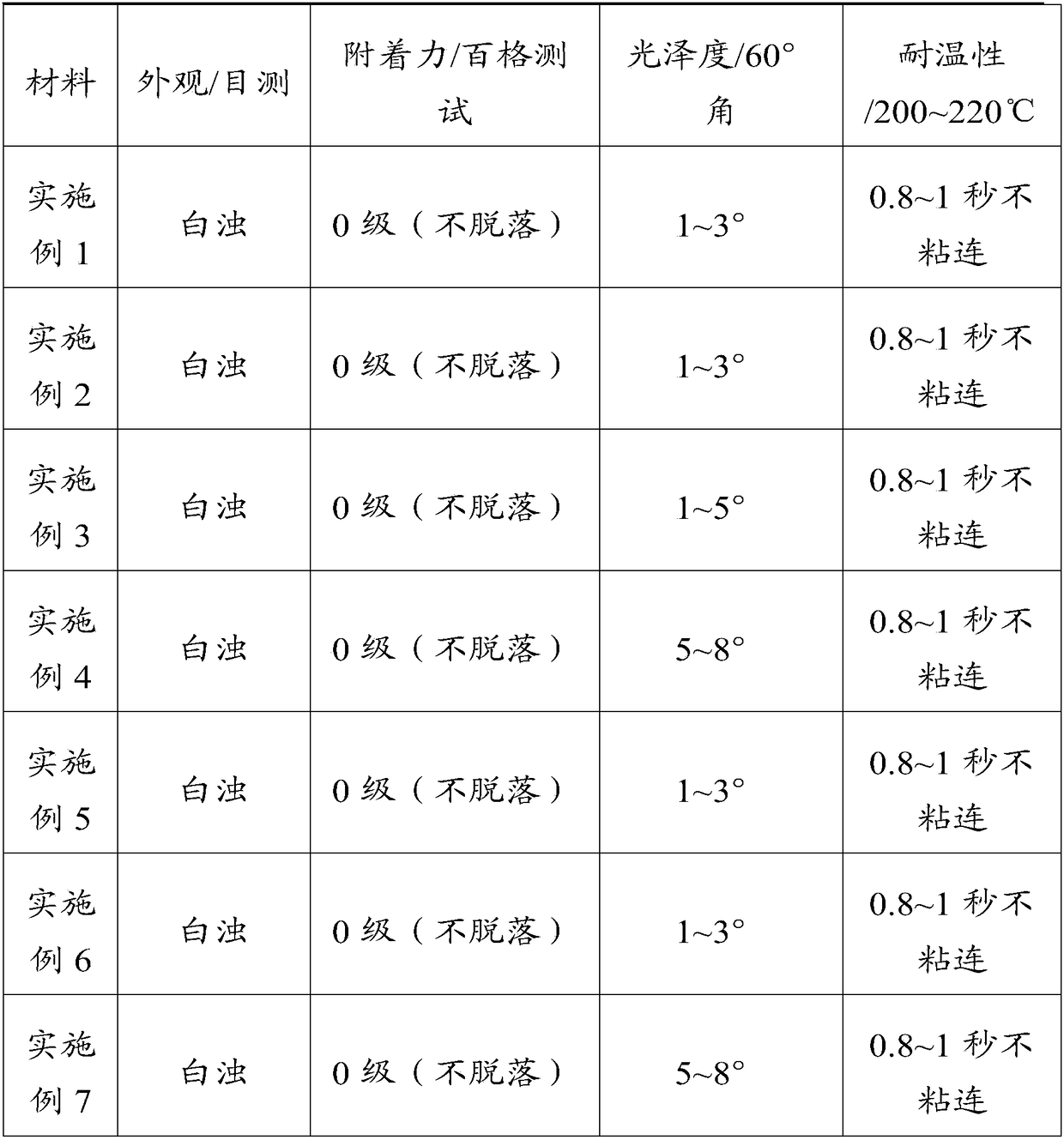

Examples

Embodiment 1

[0030] A kind of water-based environment-friendly new material used to replace PET dumb film and preparation method thereof

[0031] Composition of raw materials used to replace PET dumb film water-based environmentally friendly new materials: (unit: kg)

[0032] The parts by weight of each component in raw material A consist of: water-based matte varnish 77, pure water 13, polyurethane wear-resistant microspheres 3, nano silicon dioxide 6, organic matting agent 5 and leveling agent 2;

[0033] Composition in parts by weight of raw material B component: purified water 2;

[0034] The parts by weight of the components in the raw material C are: carbodiimide 0.5, polyethylenimide 1.5.

[0035] Prepared by:

[0036] Step S01, preparation of water-based matte varnish: prepare water-based polyurethane resin, ethanol, and film-forming aids in parts by weight, first add water-based polyurethane resin, ethanol, add film-forming aids while stirring, and quickly disperse for 20 minute...

Embodiment 2

[0045]A kind of water-based environment-friendly new material used to replace PET dumb film and preparation method thereof

[0046] Composition of raw materials used to replace PET dumb film water-based environmentally friendly new materials: (unit: kg)

[0047] The parts by weight of each component in raw material A are: water-based matte varnish 66, purified water 10, polyurethane wear-resistant microspheres 5, nano silicon dioxide 8, organic matting agent 1 and leveling agent 2;

[0048] Composition in parts by weight of raw material B component: purified water 2;

[0049] The parts by weight of the components in the raw material C are: carbodiimide 0.2, polyethylenimine 1.8.

[0050] Prepared by:

[0051] Step S01, preparation of water-based matte varnish: prepare water-based polyurethane resin, ethanol, and film-forming aids in parts by weight, first add water-based polyurethane resin, ethanol, add film-forming aids while stirring, and quickly disperse for 20 minutes to...

Embodiment 3

[0060] A kind of water-based environment-friendly new material used to replace PET dumb film and preparation method thereof

[0061] Composition of raw materials used to replace PET dumb film water-based environmentally friendly new materials: (unit: kg)

[0062] The parts by weight of each component in raw material A are: water-based matte varnish 76, pure water 12, polyurethane wear-resistant microspheres 2, nano silicon dioxide 3 and leveling agent 1;

[0063] Composition of raw material B in parts by weight: purified water 4;

[0064] The parts by weight of each component in the raw material C are: carbodiimide 0.4, polyethylenimide 1.6.

[0065] Prepared by:

[0066] Step S01, preparation of water-based matte varnish: prepare water-based polyurethane resin, ethanol, and film-forming aids in parts by weight, first add water-based polyurethane resin, ethanol, add film-forming aids while stirring, and quickly disperse for 20 minutes to prepare Get water-based matte varnis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com