A kind of high-strength flame-retardant magnesium alloy and its preparation method

A magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve problems such as inability to meet industrial applications and only tensile strength, and achieve the effects of improved performance, increased tensile strength, and increased ignition point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

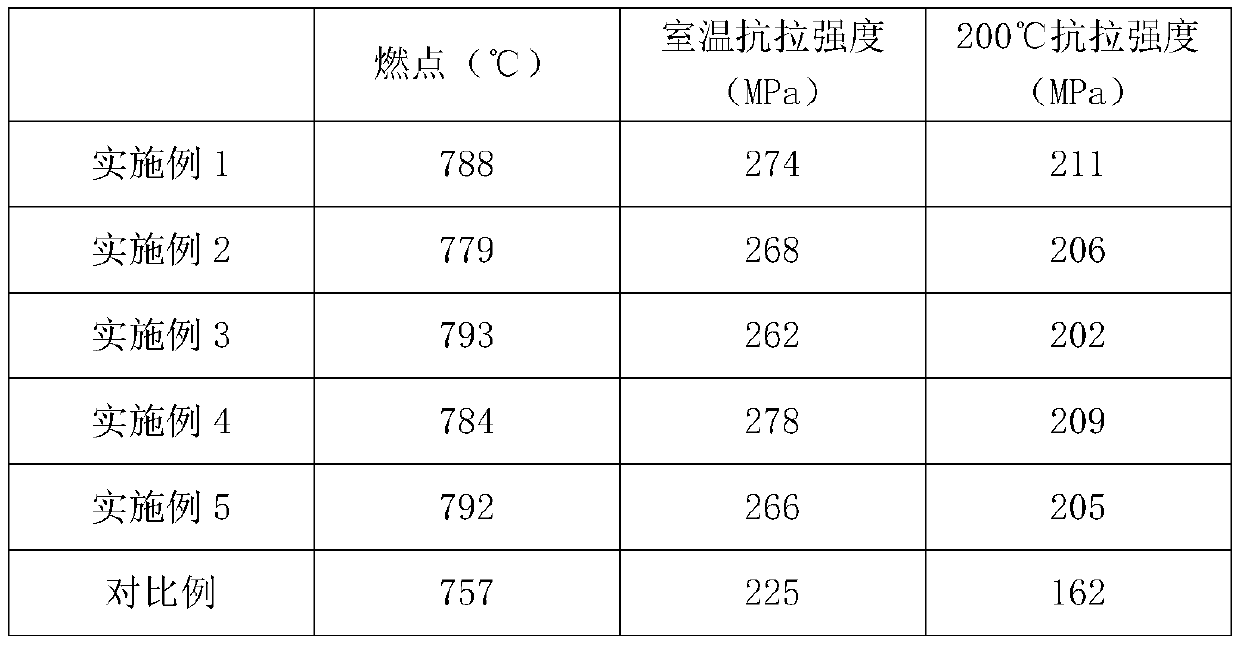

Examples

Embodiment 1

[0033] The high-strength flame-retardant magnesium alloy of this embodiment is composed of the following elements by weight: 3.5% Nd, 1.5% Sm, 2.5% Sn, 1.7% Bi, 0.3% Ca, 0.5% Nb, 0.3% The total amount of Sb impurity elements Fe, Cu and Ni is less than 0.2%, and the balance is Mg.

[0034] The preparation method of the high-strength flame-retardant magnesium alloy of the present embodiment comprises the following steps:

[0035] 1) Preheat the raw materials of pure magnesium, pure tin, pure bismuth, pure antimony, magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy and magnesium niobium master alloy at 200°C, so that the temperature of the raw materials reaches 200°C ;

[0036] 2) Put the preheated pure magnesium, pure tin, pure bismuth, and pure antimony into a corundum crucible, put it into an intermediate frequency induction furnace, and 2 +SF 6 Heating under the protection of mixed gas to melt all the raw materials to obtain ...

Embodiment 2

[0041] The high-strength flame-retardant magnesium alloy of this embodiment is composed of the following elements by weight: 3.5% Nd, 1.5% Sm, 2.4% Sn, 1.5% Bi, 0.4% Ca, 0.5% Nb, 0.4% The total amount of Sb impurity elements Fe, Cu and Ni is less than 0.2%, and the balance is Mg.

[0042] The preparation method of the high-strength flame-retardant magnesium alloy of the present embodiment comprises the following steps:

[0043] 1) Preheat the raw materials of pure magnesium, pure tin, pure bismuth, pure antimony, magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy and magnesium niobium master alloy at 200°C, so that the temperature of the raw materials reaches 200°C ;

[0044] 2) Put the preheated pure magnesium, pure tin, pure bismuth, and pure antimony into a corundum crucible, put it into an intermediate frequency induction furnace, and 2 +SF 6 Heating under the protection of mixed gas to melt all the raw materials to obtain ...

Embodiment 3

[0049] The high-strength flame-retardant magnesium alloy of this embodiment is composed of the following elements by weight: 3.5% Nd, 1.5% Sm, 2.4% Sn, 1.5% Bi, 0.6% Ca, 0.5% Nb, 0.45% The total amount of Sb impurity elements Fe, Cu and Ni is less than 0.2%, and the balance is Mg.

[0050] The preparation method of the high-strength flame-retardant magnesium alloy of the present embodiment comprises the following steps:

[0051] 1) Preheat the raw materials of pure magnesium, pure tin, pure bismuth, pure antimony, magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy and magnesium niobium master alloy at 200°C, so that the temperature of the raw materials reaches 200°C ;

[0052] 2) Put the preheated pure magnesium, pure tin, pure bismuth, and pure antimony into a corundum crucible, put it into an intermediate frequency induction furnace, and 2 +SF 6 Heating under the protection of mixed gas to melt all the raw materials to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com