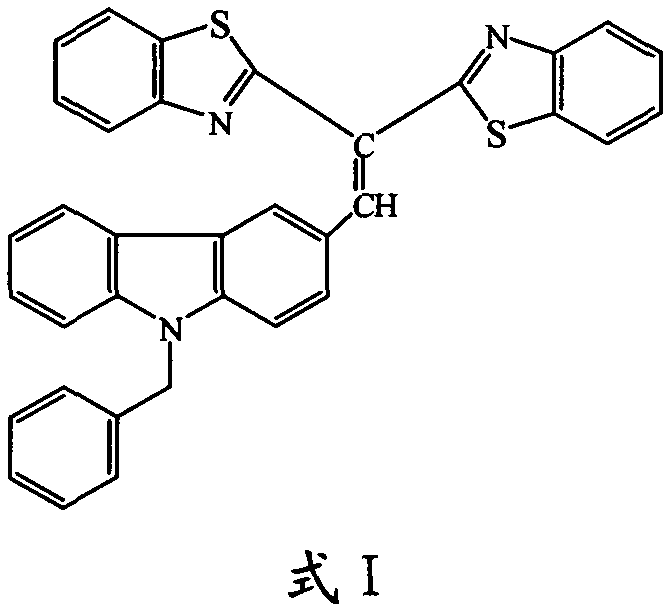

Steel corrosion inhibitor and preparation method thereof

A technology of corrosion inhibitor and steel, applied in the field of metal corrosion inhibition, can solve the problems of difficult to meet environmental protection, low toxicity and low cost, complex synthesis and preparation process, large environmental pollution load, etc., and achieves low cost, low dosage, Low environmental toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

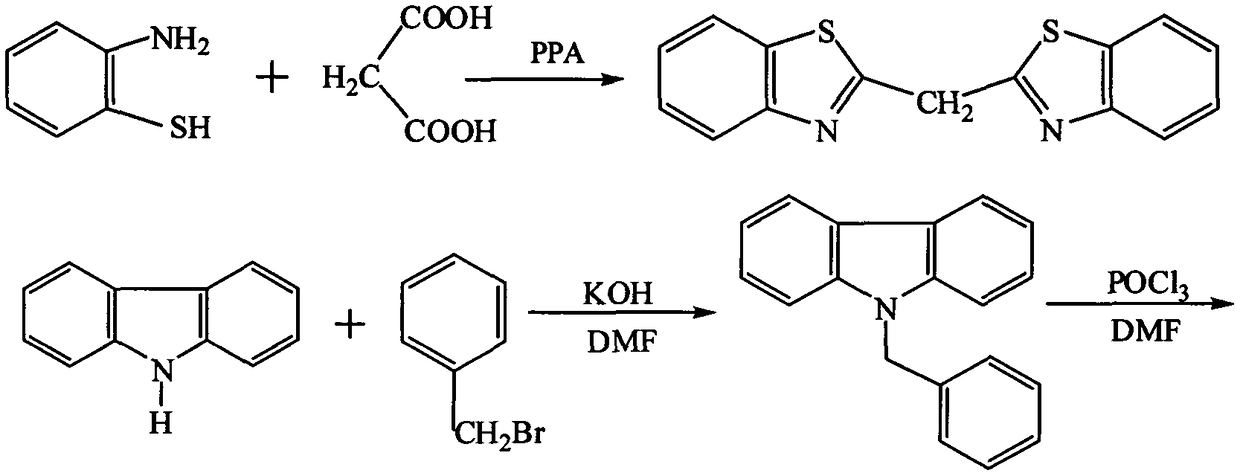

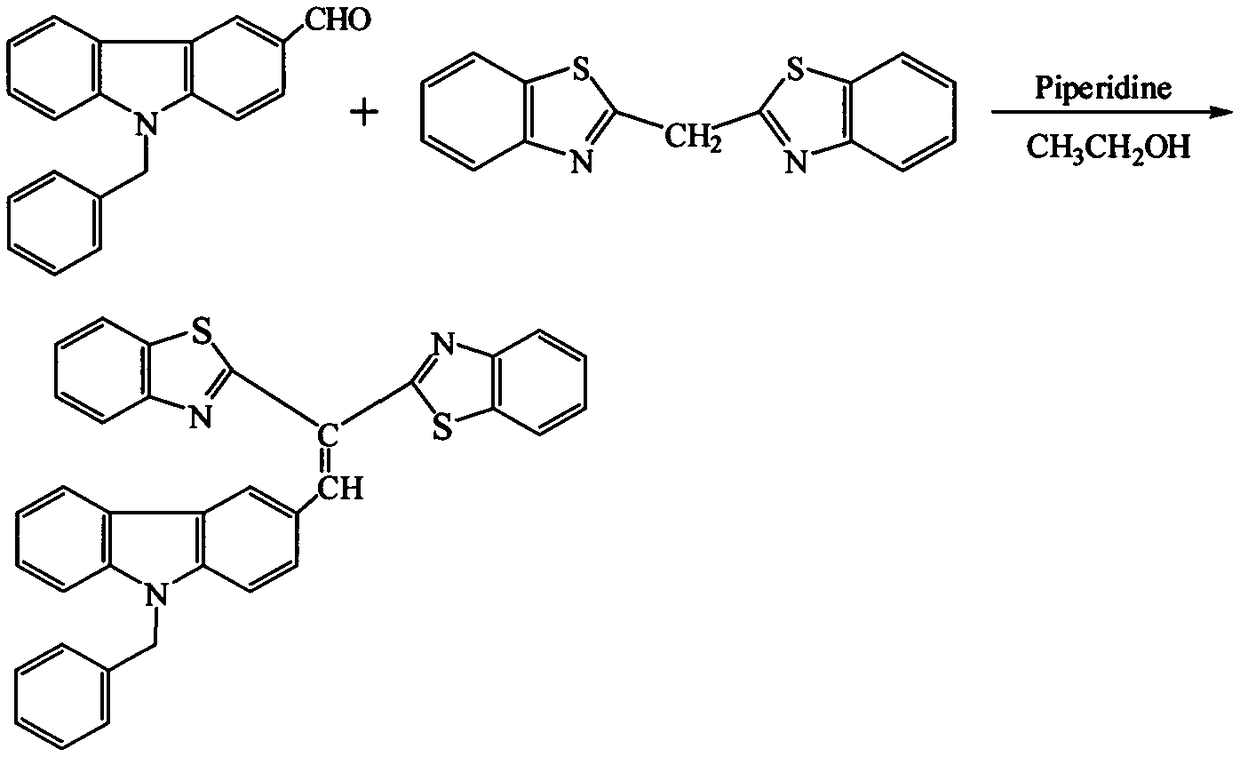

Method used

Image

Examples

Embodiment 1

[0032] A steel corrosion inhibitor with 1,1-bis(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene as the core corrosion inhibitor component, according to the following weight percentage (w %) species composition: 1,1-bis(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene 2.0%, ethanol 5.0%, fatty alcohol polyoxyethylene ether sulfuric acid Sodium (AES) 0.5%, dispersant PEG 4001.5%, balance water 91.0%.

[0033] The preparation method of the corrosion inhibitor is as follows: at room temperature, take 50g of ethanol according to the above ratio and add it to a mixing tank, stirring tank or tank, then add 100g of water, and then weigh 1,1-bis(benzothiazol-2-yl) -20g of 2-(N-benzylcarbazol-3-yl)ethylene was added to the aqueous ethanol solution, then 5g of AES, 15g of PEG400 and 810g of the remaining water were added, and the corrosion inhibitor was obtained by stirring evenly.

[0034] This formula corrosion inhibitor is used for the corrosion inhibition test of steel: two...

Embodiment 2

[0036] A steel corrosion inhibitor with 1,1-bis(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene as the core corrosion inhibitor component, according to the following weight percentage (w %) species composition: 1,1-di(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene 4.0%, acetic acid 3.0%, sodium lauryl sulfate ( K12) 1.0%, dispersant PEG 200 2.0%, balance water 90.0%.

[0037] The preparation method of the corrosion inhibitor is as follows: at room temperature, weigh 30g of acetic acid according to the above ratio and add it to a mixing tank, stirring tank or tank, add 100g of water, stir and mix, then weigh 1,1-bis(benzothiazole-2 - Base)-2-(N-benzylcarbazol-3-yl)ethylene 40g was added to the above-mentioned aqueous solution of acetic acid, and then 10g of sodium lauryl sulfate (K12), 20g of dispersant PEG200 and 800g of remaining water were added , Stir evenly to get the corrosion inhibitor.

[0038] The corrosion inhibitor of this formula is used for the corrosi...

Embodiment 3

[0040] A steel corrosion inhibitor with 1,1-bis(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene as the core corrosion inhibitor component, according to the following weight percentage (w %) species composition: 1,1-bis(benzothiazol-2-yl)-2-(N-benzylcarbazol-3-yl)ethylene 2.5%, DMF 6.0%, fatty alcohol polyoxyethylene ether sulfuric acid Sodium (AES) 0.5%, PEG400 2.0%, balance water 89.0%.

[0041] The preparation method of the corrosion inhibitor is as follows: at room temperature, weigh 60g of DMF according to the above ratio and add it to a mixing tank, stirring tank or tank, add 150g of water, stir to make it completely dissolve, then weigh 1,1-bis(benzothiazole Add 25g of -2-yl)-2-(N-benzylcarbazol-3-yl)ethylene to the above DMF aqueous solution, then add 5g of AES, 20g of PEG400 and 740g of the remaining water, and stir well to obtain the corrosion inhibitor agent.

[0042] This formula corrosion inhibitor is used for the corrosion inhibition test of steel materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com