Method for synthesizing large-size lead telluride monocrystalline thermovoltaic material

A synthesis method and technology of lead telluride, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc. Micron, nanometer level and other issues, to achieve the effect of low loss, high conversion efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the high-temperature solid-phase reaction method uses the same process to prepare lead telluride polycrystalline positive and negative thermal volt materials.

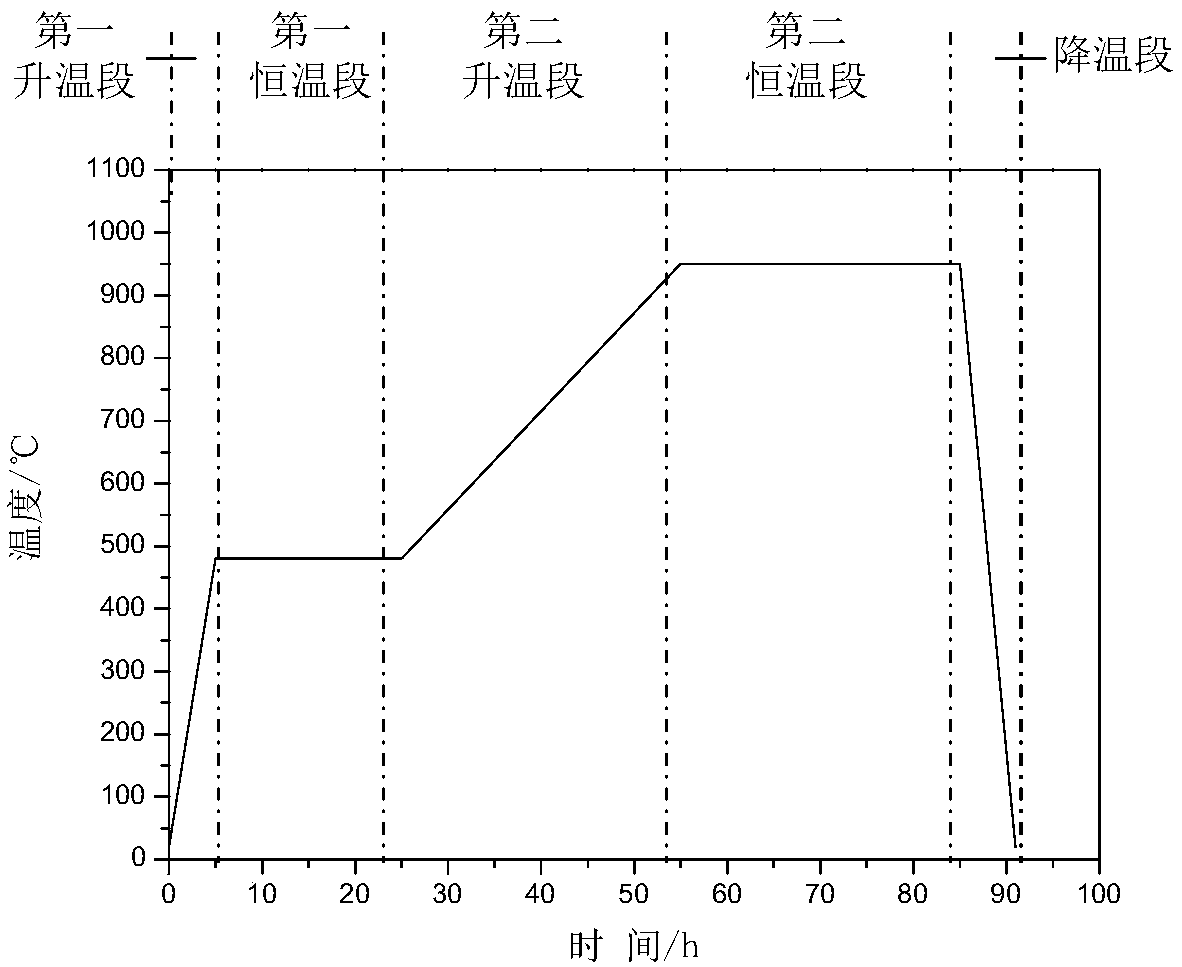

[0046] Attached figure 2 The best process for preparing lead telluride polycrystalline positive and negative thermovoltaic materials by high-temperature solid-phase reaction method is given: the first heating section starts from room temperature, and after 8 hours, the temperature is increased to 500°C, and then enters the first constant temperature. After keeping it for 24 hours, it enters the second heating section, which takes 24 hours to raise the temperature to 1000°C, and then enters the second constant temperature section. The polycrystalline lead telluride positive electrode and negative electrode thermal volt materials were obtained respectively.

Embodiment 2

[0048] In this embodiment, the high-temperature solid-phase reaction method uses the same process to prepare lead telluride polycrystalline positive and negative thermal volt materials.

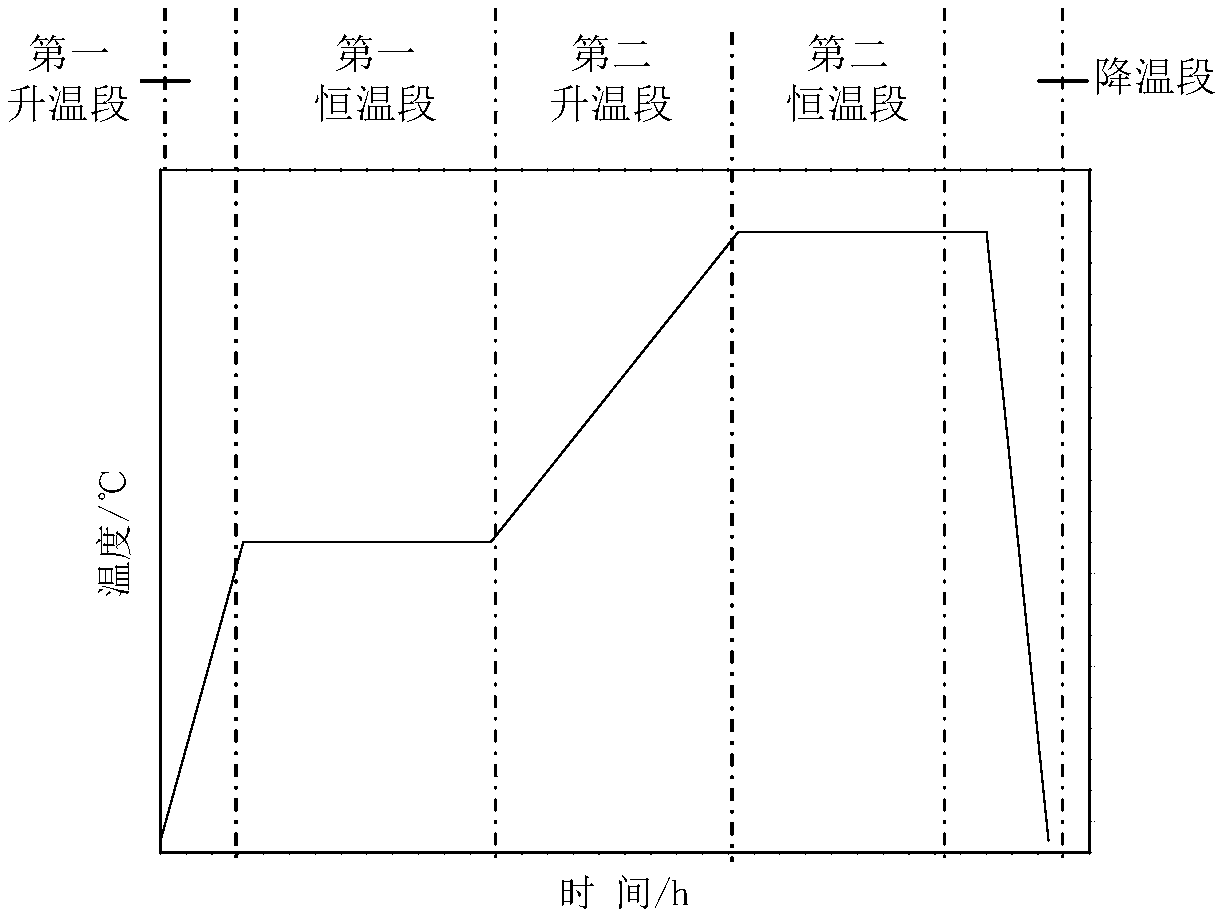

[0049] Attached image 3 Gives another best synthesis process for preparing lead telluride polycrystalline positive and negative thermovoltaic materials by high-temperature solid-phase reaction: the first heating stage starts from room temperature, and after 5 hours, the temperature is raised to 480°C, and then enters The first constant temperature section is kept for 20 hours, and then it enters the second temperature rise section, which takes 30 hours to heat up to 950°C, and then enters the second constant temperature section when the temperature is reached. After 30 hours of heat preservation, it enters the temperature drop section and cools to 150°C / hour. At room temperature, the polycrystalline lead telluride positive electrode and negative electrode thermal volt materials were obtained res...

Embodiment 3

[0054] See attached Figure 5 .

[0055] In this embodiment, the same process is used to make large-size lead telluride single crystal positive and negative thermal volt materials.

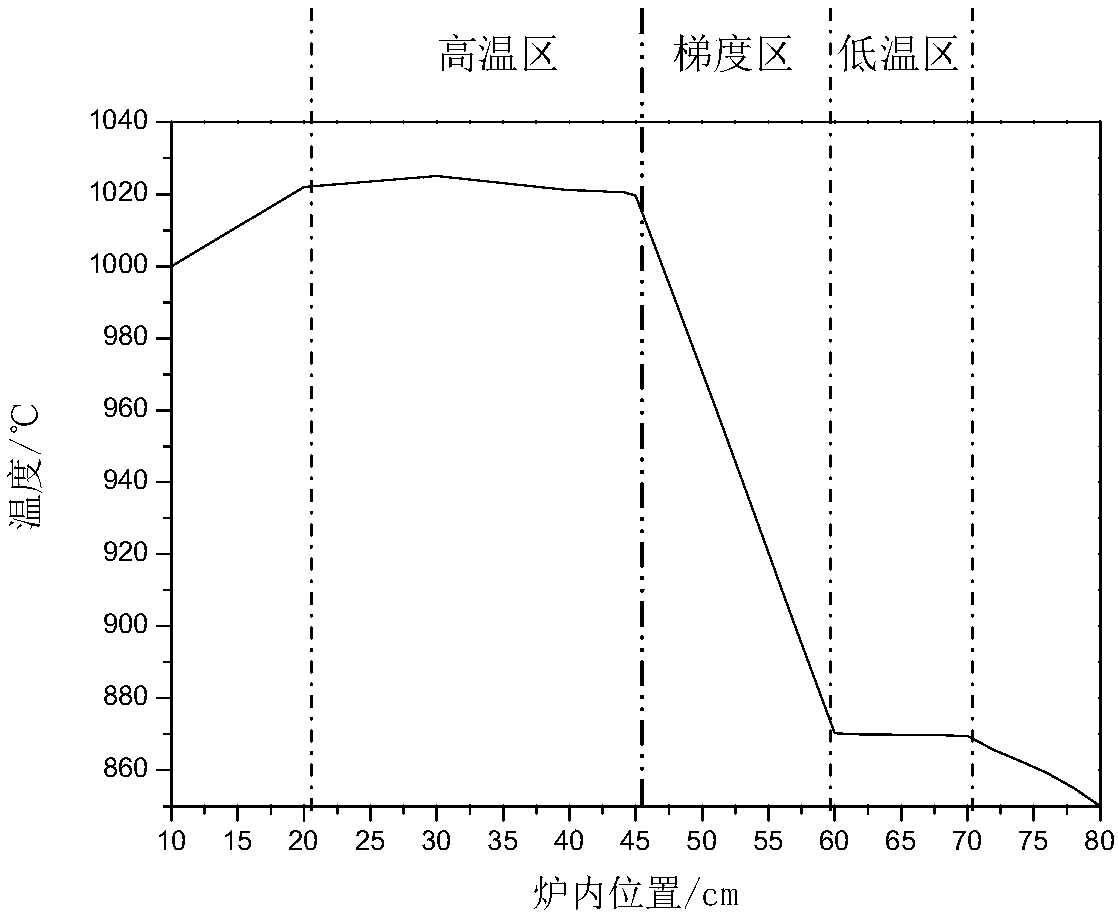

[0056] The polycrystalline positive electrode and negative electrode thermal source materials prepared in Example 1 were respectively packed into large-size quartz growth ampoules with an inner diameter of 50 mm and a length of 350 mm. After the temperature rises, the high temperature zone is around 1010°C, and the gradient zone drops from 1010°C to around 830°C, and then maintains around 830°C. During operation, first place the bottom end of the growth ampoule at 45cm in the furnace. After 50 hours of rest, slowly lower the growth ampoule at a rate of 0.5mm / hour. When the bottom end of the quartz ampoule reaches 75cm, stop the drop and take out the growth ampoule by cooling down. , To obtain large-size lead telluride single crystal positive and negative thermal volt materials. The lead telluride sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com