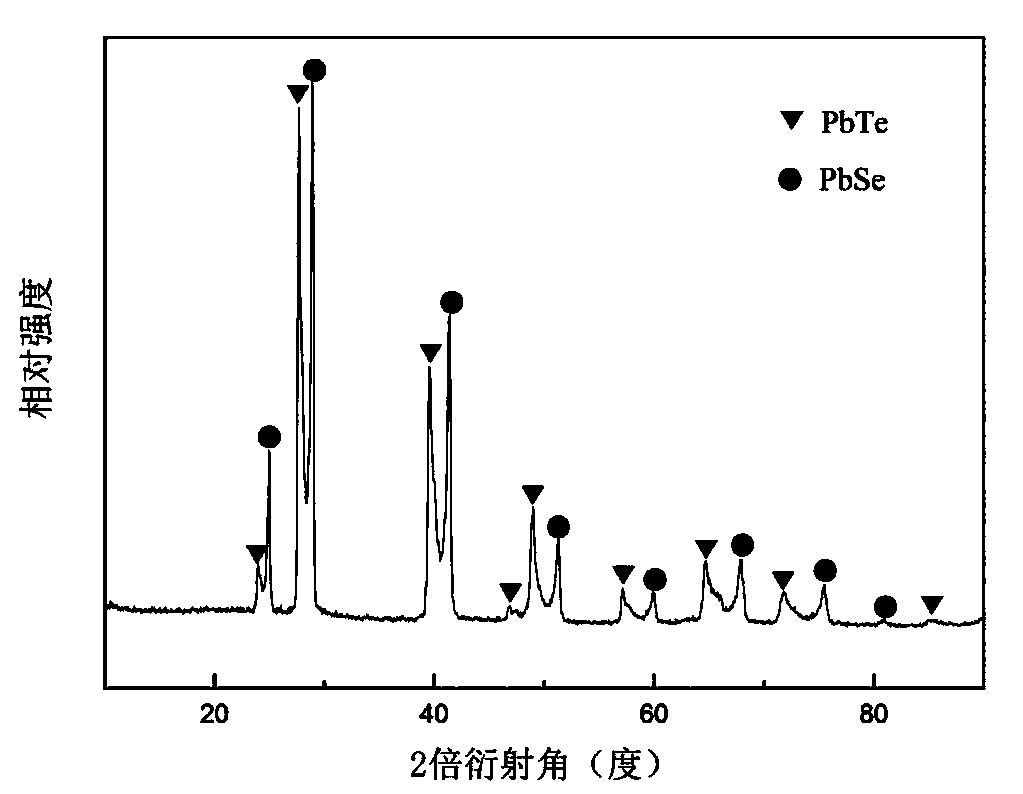

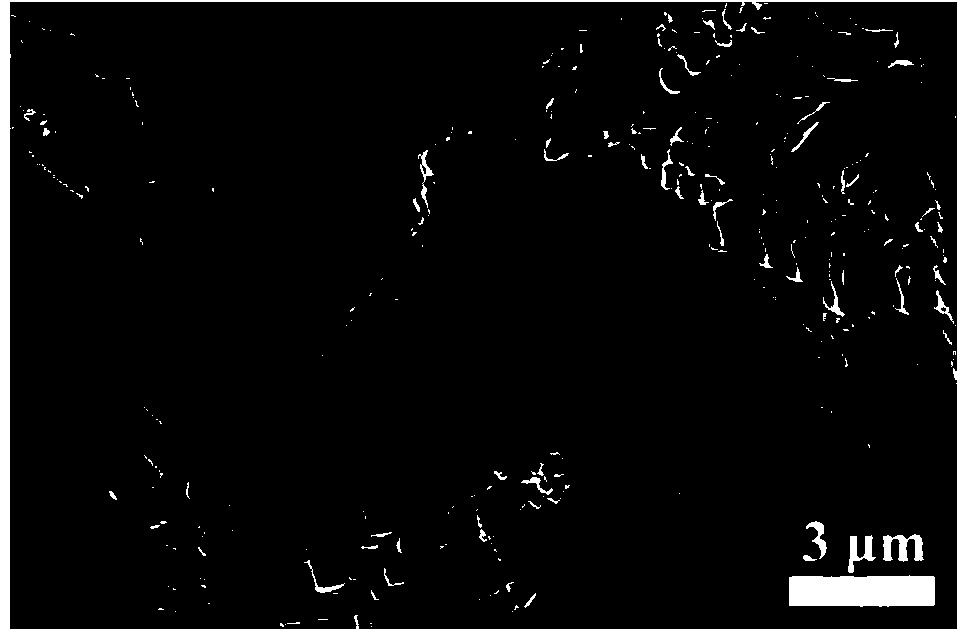

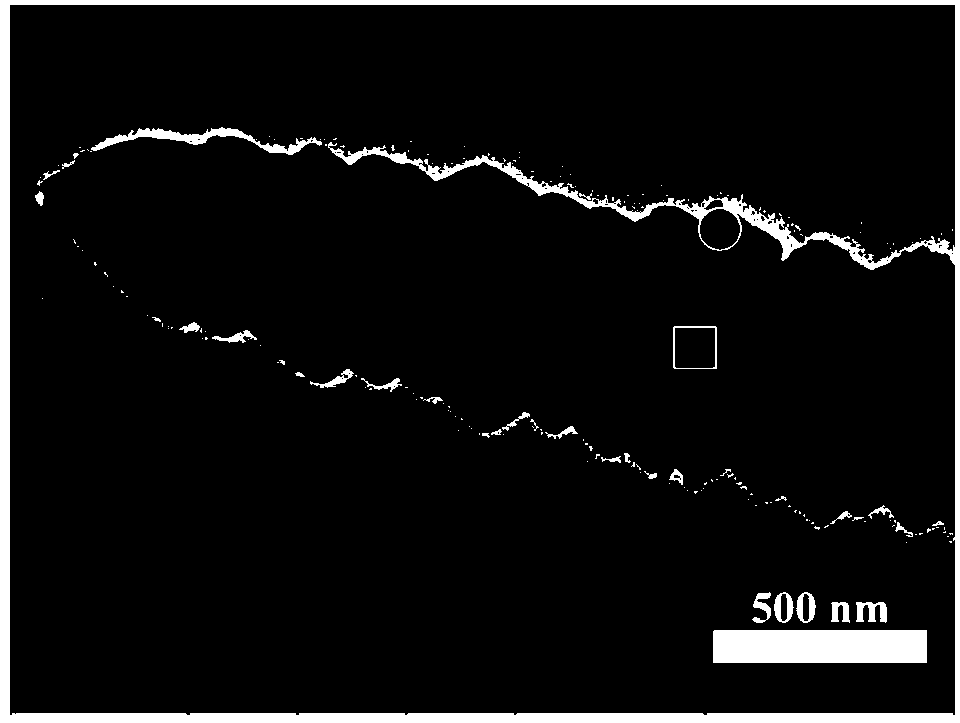

Lead selenide coated lead telluride dendritic crystal composite and preparation method thereof

A composite material, lead telluride technology, applied in binary selenium/tellurium compounds, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of low temperature, high product purity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) The raw material Pb(CH 3 COO) 2 ·3H 2 O,TeO 2 and SeO 2 Dissolved in 30mL aqueous sodium hydroxide solution, Pb(CH 3 COO) 2 .3H 2 O,TeO 2 and SeO 2 The molar masses are 3mmol, 1.5mmol, 1.5mmol respectively, and 0.3g NaBH is added at the same time 4 as a reducing agent;

[0023] 2) Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for hydrothermal reaction;

[0024] 3) Transfer the precursor solution obtained in step 2) into a polytetrafluoroethylene-lined reaction kettle, then put the reaction kettle into an oven, and stop the reaction after keeping the temperature at 180°C for 20 hours;

[0025] 4) After the reaction temperature drops to room temperature, take out the reaction kettle, separate the precipitate, wash it with deionized water and absolute ethanol until neutral, and dry it at a constant temperature at 60°C to obtain pure lead selenide-coated telluride Lead composite powder.

[...

Embodiment 2

[0028] 1) The raw material Pb(CH 3 COO) 2 ·3H 2 O,TeO 2 and SeO 2 Dissolved in 30mL aqueous sodium hydroxide solution, Pb(CH 3 COO) 2 .3H 2 O,TeO 2 and SeO 2 The molar masses are 3mmol, 1.5mmol, 1.5mmol respectively, and 0.3g NaBH is added at the same time 4 as a reducing agent;

[0029] 2) Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for hydrothermal reaction;

[0030] 3) Transfer the precursor solution obtained in step 2) into a polytetrafluoroethylene-lined reaction kettle, then put the reaction kettle into an oven, and stop the reaction after keeping the temperature at 180°C for 18 hours;

[0031] 4) After the reaction temperature drops to room temperature, take out the reaction kettle, separate the precipitate, wash it with deionized water and absolute ethanol until neutral, and dry it at a constant temperature at 60°C to obtain pure lead selenide-coated telluride Lead composite powder.

Embodiment 3

[0033] 1) The raw material Pb(CH 3 COO) 2 ·3H 2 O,TeO 2 and SeO 2 Dissolved in 30mL aqueous sodium hydroxide solution, Pb(CH 3 COO) 2 .3H 2 O,TeO 2 and SeO 2 The molar masses are 3mmol, 1.5mmol, 1.5mmol respectively, and 0.3g NaBH is added at the same time 4 as a reducing agent;

[0034] 2) Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for hydrothermal reaction;

[0035] 3) Transfer the precursor solution obtained in step 2) into a polytetrafluoroethylene-lined reaction kettle, then put the reaction kettle into an oven, and stop the reaction after keeping the temperature at 180°C for 22 hours;

[0036] 4) After the reaction temperature drops to room temperature, take out the reaction kettle, separate the precipitate, wash it with deionized water and absolute ethanol until neutral, and dry it at a constant temperature at 60°C to obtain pure lead selenide-coated telluride Lead composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com