Ceramic solar heating heat-storing system for greenhouse

A greenhouse and heat storage system technology, applied in solar heating systems, solar heat storage, solar thermal energy, etc., can solve problems such as short service life, high price, and low bonding energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

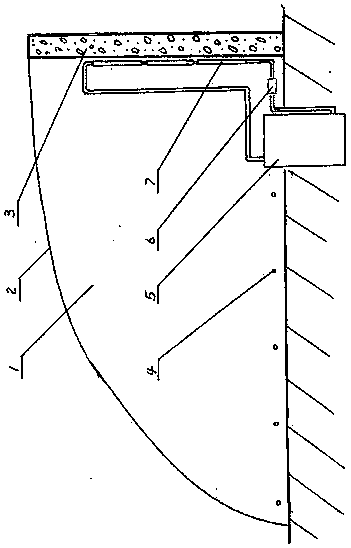

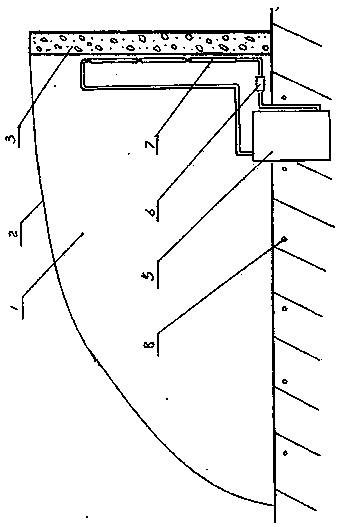

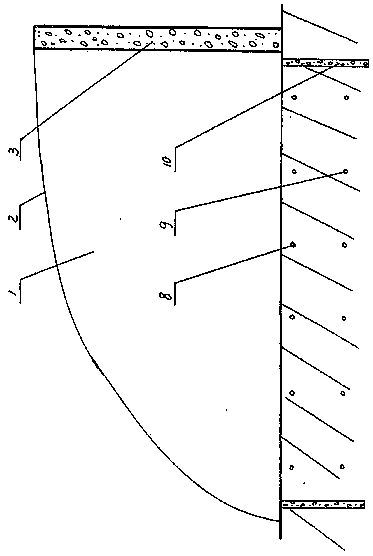

Embodiment Construction

[0044] 1. Groove along the surrounding edges on the ground in the greenhouse, the groove width is 300 mm, and the depth is 3000 mm. The groove is filled with polystyrene foam boards to reduce the heat loss of the soil in the greenhouse; grooves are made on the ground in the greenhouse , the groove width is 300 mm, the depth is 2000 mm, and the groove distance is 3000 mm. Deep soil heating heat storage pipes are embedded in the grooves. The depth of deep soil heating heat storage pipes is 2000 mm. The buried depth of the soil heating pipe is 500 mm; in the greenhouse planting area, a new building with an anchor pile structure and a side-slope ceramic solar roof is used. A slope ceramic solar roof heating system is composed of ceramic solar panels, thermal insulation water tanks, small water pumps, controllers, etc.; The way is to heat the deep soil through the deep soil heating pipeline to increase the soil temperature, and form inter-seasonal heat storage in the deep soil. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com