Low-pressure diffusion process applied to polycrystalline black silicon solar cells

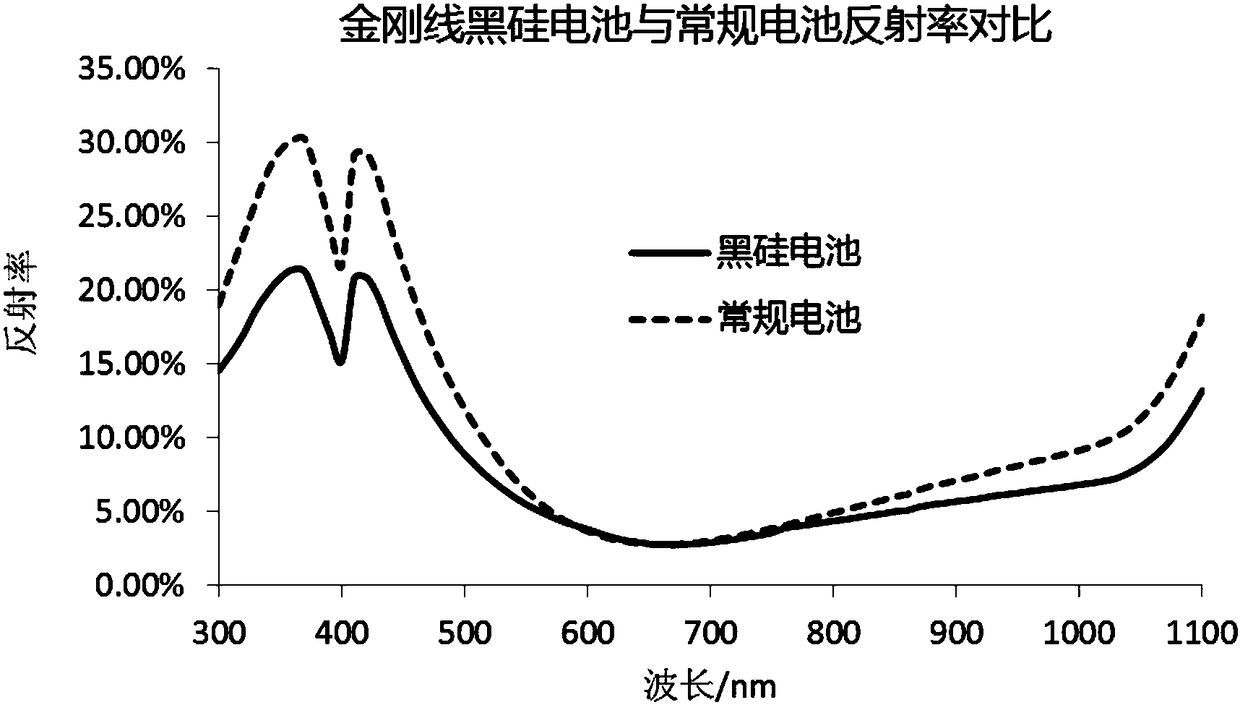

A solar cell and diffusion process technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor sheet resistance uniformity, and achieve the effects of increasing filling factor, increasing surface doping concentration, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

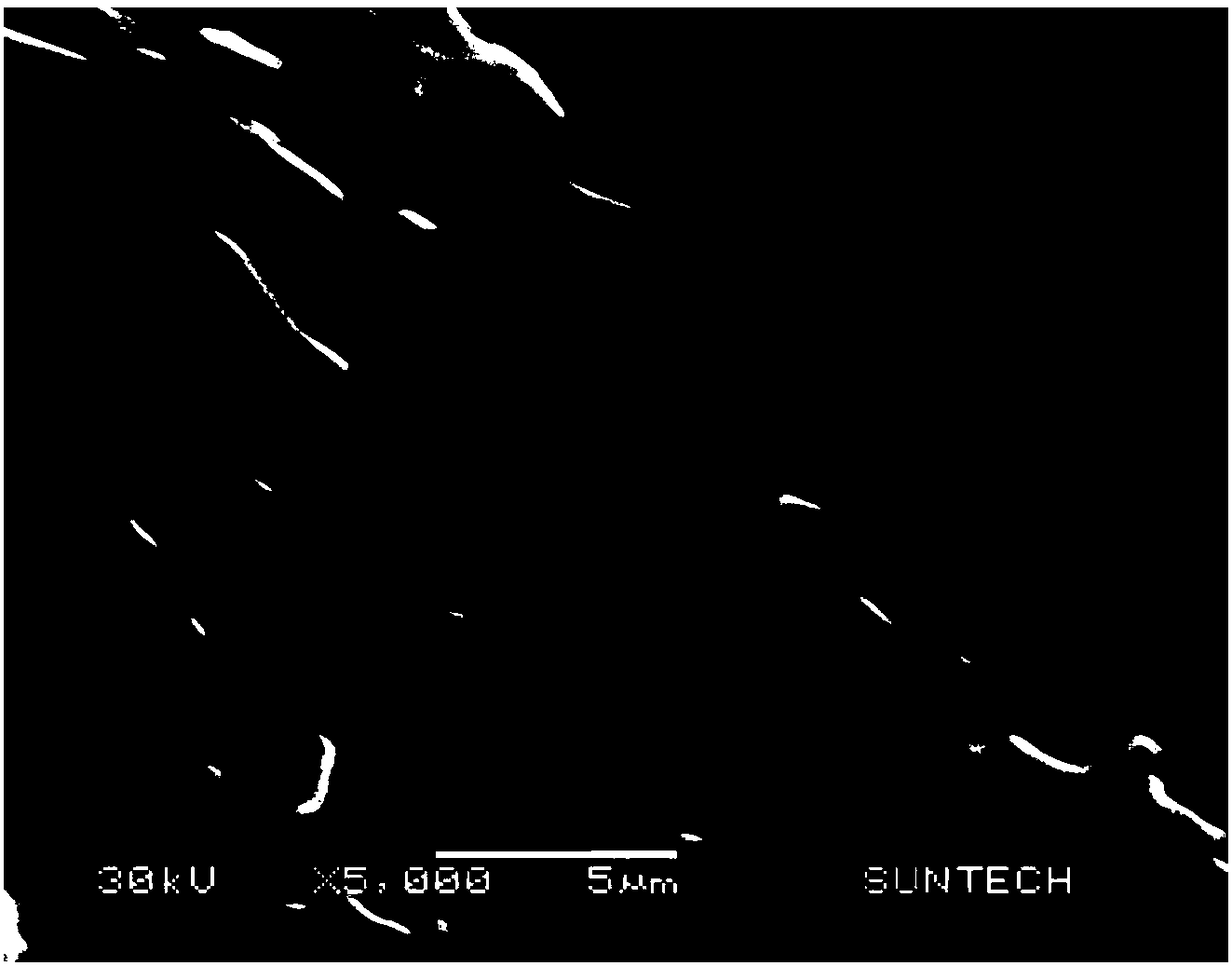

[0029] Choose 156.75mm*156.75mm P-type diamond wire-cut polysilicon wafer as the base material, with a resistivity of 3Ω·cm, after alkali polishing, pickling, immersion silver, digging, desilvering, hole expansion, alkali cleaning, pickling, water washing 1. drying to prepare the textured surface, the thinning amount of the textured surface is 0.38g, the aperture of the nano-textured surface is 500nm, and the surface reflectance of the silicon wafer after the textured process is 19.5%. Load the textured black silicon wafer into the diffusion quartz boat to prepare for diffusion.

[0030] The diffusion process is shown in Table 1:

[0031] Table 1

[0032]

[0033] The sheet resistance value after diffusion according to the process parameters of Example 1. Take 2 slices from the furnace mouth, the middle of the furnace, and the end of the furnace respectively, test the square resistance value of 9 points on each slice, and calculate the average value of the square resistan...

Embodiment 2

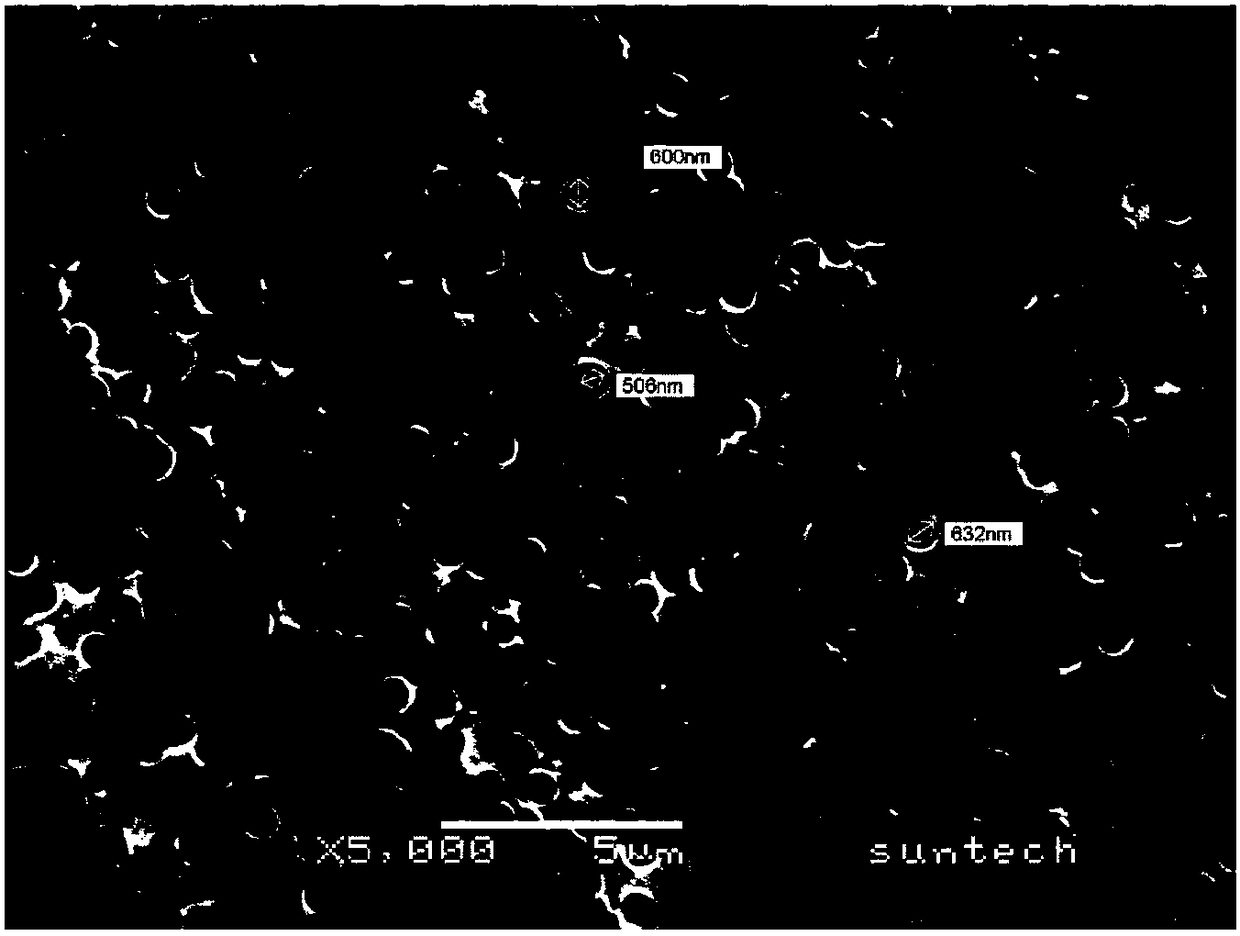

[0043] Choose 156.75mm*156.75mm P-type diamond wire-cut polycrystalline silicon wafer as the base material, with a resistivity of 2Ω·cm, after alkali polishing, pickling, immersion silver, digging, desilvering, hole expansion, alkali cleaning, pickling, water washing 1. drying to prepare the textured surface, the thinning amount of the textured surface is 0.45g, the aperture of the nano-textured surface is 700nm, and the surface reflectance of the silicon wafer after the textured process is 21.0%. The textured black silicon wafers are loaded into the diffusion quartz boat for diffusion.

[0044] The diffusion process is shown in Table 4.

[0045] Table 4

[0046]

[0047]

[0048] Sheet resistance value after diffusion according to the process parameters of Example 2. Take 2 slices from the furnace mouth, the middle of the furnace, and the end of the furnace respectively, test the square resistance value of 9 points on each slice, and calculate the average value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com