Method for preparing supported palladium catalyst used for benzene catalytic oxidation

A technology of catalytic oxidation and supported palladium, which is applied in the field of preparation of supported palladium catalysts, can solve the problems of platinum catalyst limitations, high platinum loading, and expensive platinum, and achieve good catalytic activity, convenient source, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 2.0g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 50 mL of ethanol and stirred for 0.5 h;

[0034] (2) Add 1.0 g of SBA-15 and stir until the solvent is completely evaporated to obtain a white solid, which is roasted in a muffle furnace at 600°C for 6 hours;

[0035] (3) react the obtained product in 2mol / L NaOH solution at 75°C for 2h, centrifuge and dry to obtain the carrier CeO 2 ;

[0036] (4) Take 20 mL of 3.0 g / L Cinnamomum camphora extract, mix it with 135 μL of 75 mM palladium nitrate, stir at 90°C for 1 hour, and adjust the pH to 2;

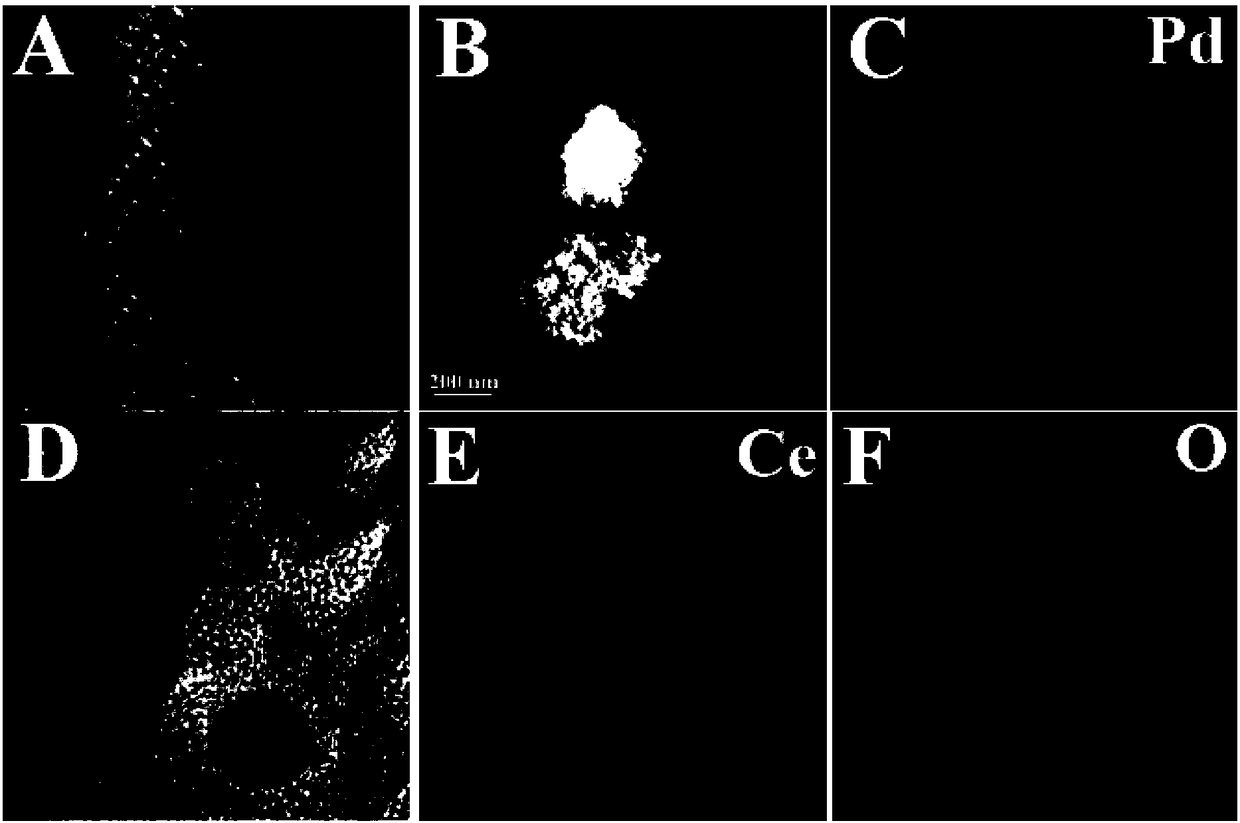

[0037] (5) Add 0.2g of CeO to the solution 2 Carrier, stirred for 1h, filtered and washed, dried at 50°C for 12h to obtain figure 1 Loadings shown are 0.5% Pd / CeO 2 Catalyst, recorded as 0.5Pd / CeO 2 catalyst.

Embodiment 2

[0039] (1) 2.0g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 50 mL of ethanol and stirred for 0.5 h;

[0040] (2) Add 1.0 g of SBA-15 and stir until the solvent is completely evaporated to obtain a white solid, which is roasted in a muffle furnace at 500°C for 6 hours;

[0041] (3) react the obtained product in 2mol / L NaOH solution at 75°C for 2h, centrifuge and dry to obtain the carrier CeO 2 ;

[0042] (4) Take 15 mL of 3.0 g / L Cinnamomum camphora extract, mix it with 270 μL of 75.1 mM palladium nitrate, stir at 90°C for 1 hour, and adjust the pH to 2;

[0043] (5) Add 0.2g of CeO to the solution 2 Carrier, stirred for 1h, filtered and washed, dried at 50°C for 12h to obtain Pd / CeO with a loading capacity of 1.0% 2 Catalyst, denoted as 1.0Pd / CeO 2 catalyst.

Embodiment 3

[0045] (1) 2.0g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 50 mL of ethanol and stirred for 0.5 h;

[0046] (2) Add 1.0 g of SBA-15 and stir until the solvent is completely evaporated to obtain a white solid, which is roasted at 400°C for 4 hours in a muffle furnace;

[0047] (3) react the obtained product in 2mol / L NaOH solution at 75°C for 2h, centrifuge and dry to obtain the carrier CeO 2 ;

[0048] (4) Take 30 mL of 3.0 g / L Cinnamomum camphora extract, mix it with 540 μL of 75.1 mM palladium nitrate, stir at 90°C for 1 hour, and adjust the pH to 2;

[0049] (5) Add 0.2g of CeO to the solution 2 Carrier, stirred for 1h, filtered and washed, dried at 50°C for 12h to obtain Pd / CeO with a loading capacity of 2.0% 2 Catalyst, denoted as 2.0Pd / CeO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com