Method for synthesizing niobate sheet-shaped formwork powder

A synthesis method and niobate technology are applied in the synthesis field of lead-free piezoelectric ceramic powder, which can solve the problems of cumbersome cleaning process, complicated mixing process, low efficiency, etc., and achieve uniform particle distribution, simple production process, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The synthesis method of the niobate flaky template powder of the present embodiment comprises the following steps:

[0039] (1) Prepare the niobate precursor solution, the specific operation includes the following sub-steps:

[0040] (1a) Preparation of raw materials; with KOH, NaOH, Nb 2 o 5 1. Surfactant—sodium dodecylbenzenesulfonate (SDBS) is prepared as a raw material, and the addition amount of each raw material is as follows:

[0041] The selected autoclave lining capacity is 50mL, OH - Concentration is 6mol / L, according to K / Na=0.5 (molar ratio), weigh analytically pure KOH=3.499g, NaOH=4.412g, Nb 2 o 5 = 1.25g, SDBS = 0.02g.

[0042] (1b) Preparation of precursor solution;

[0043] Pour the weighed KOH and NaOH into container A with 30mL of deionized water—the beaker, and stir for about 5 minutes. After stirring evenly, pour in Nb 2 o 5 The powder was continuously stirred for 15 minutes to obtain a raw material suspension.

[0044]Take another containe...

Embodiment 2

[0050] This implementation differs from Example 1 in that: in step (2), when the reaction kettle is placed in an oven for reaction, the reaction time is 16 hours and the temperature is 100°C.

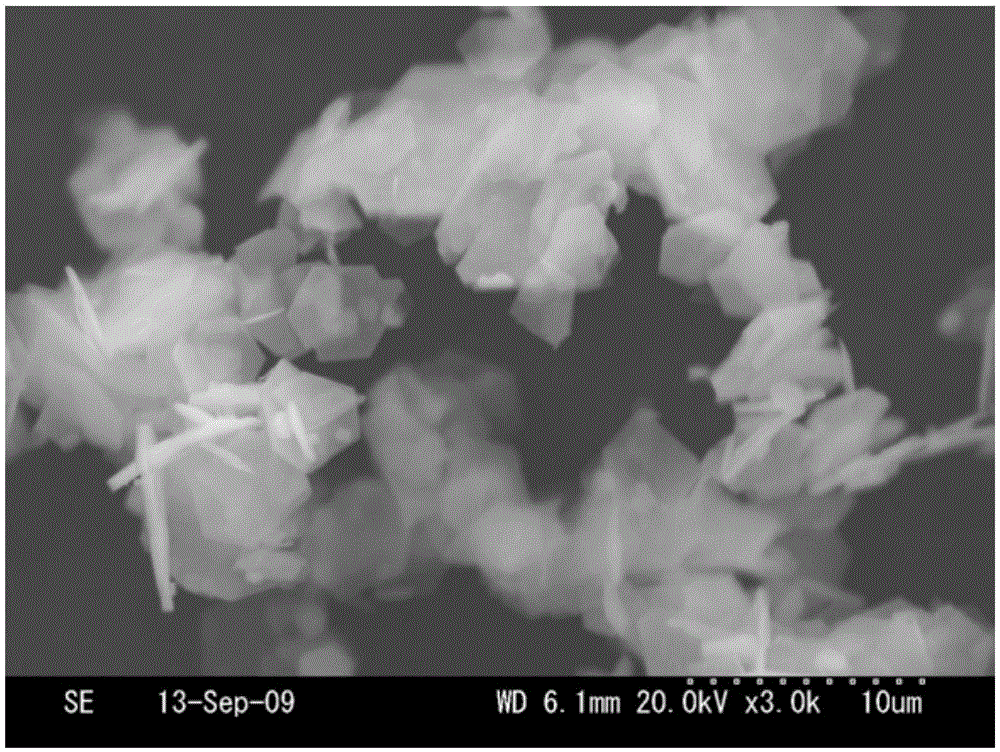

[0051] The synthesis conditions of this embodiment can also synthesize potassium sodium niobate crystalline hydrate, and its X-ray diffraction picture is as attached Figure 4 Shown, compared to K 4 Na 4 Nb 6 o 19 9H 2 O; by attaching Figure 5 The scanning electron microscope photos show that the hydrate has a clear hexagonal sheet shape.

Embodiment 3

[0053] This implementation differs from Example 1 in that: in step (2), when the reaction kettle is placed in an oven for reaction, the reaction time is 6 hours and the temperature is 180°C.

[0054] Other synthesis steps of the niobate flaky template powder in this example are the same as in Example 1.

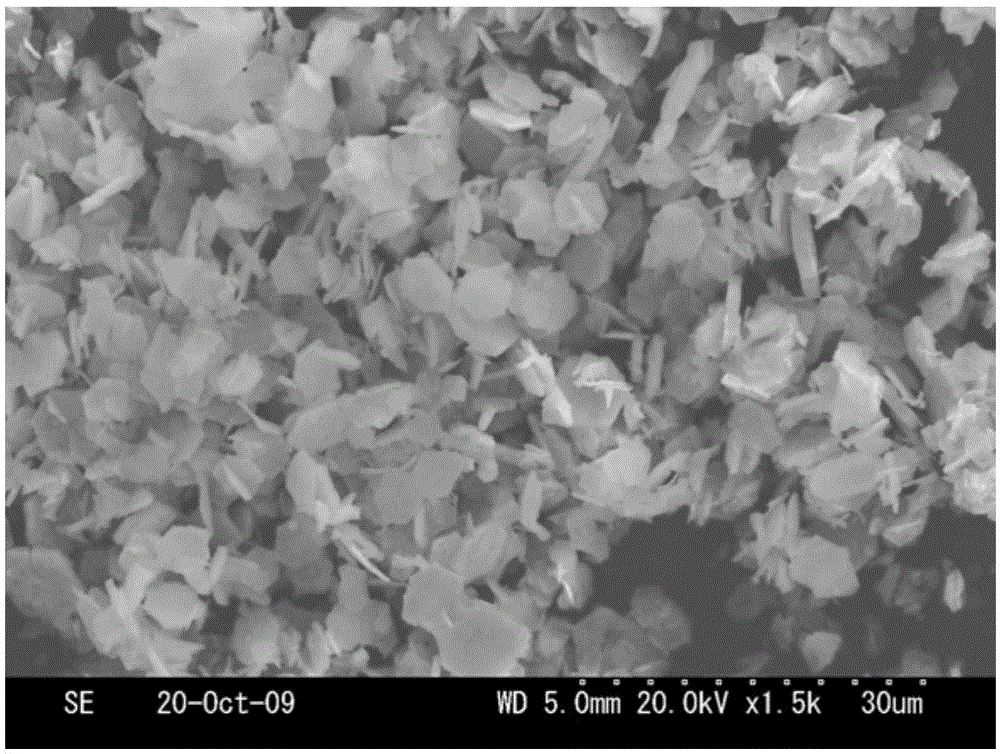

[0055] The synthesis conditions of this embodiment can also synthesize potassium sodium niobate crystalline hydrate, and its X-ray diffraction picture is as attached Image 6 Shown, compared to K 4 Na 4 Nb 6 o 19 9H 2 O; by attaching Figure 7 The scanning electron microscope photos show that the hydrate has a clear hexagonal sheet shape.

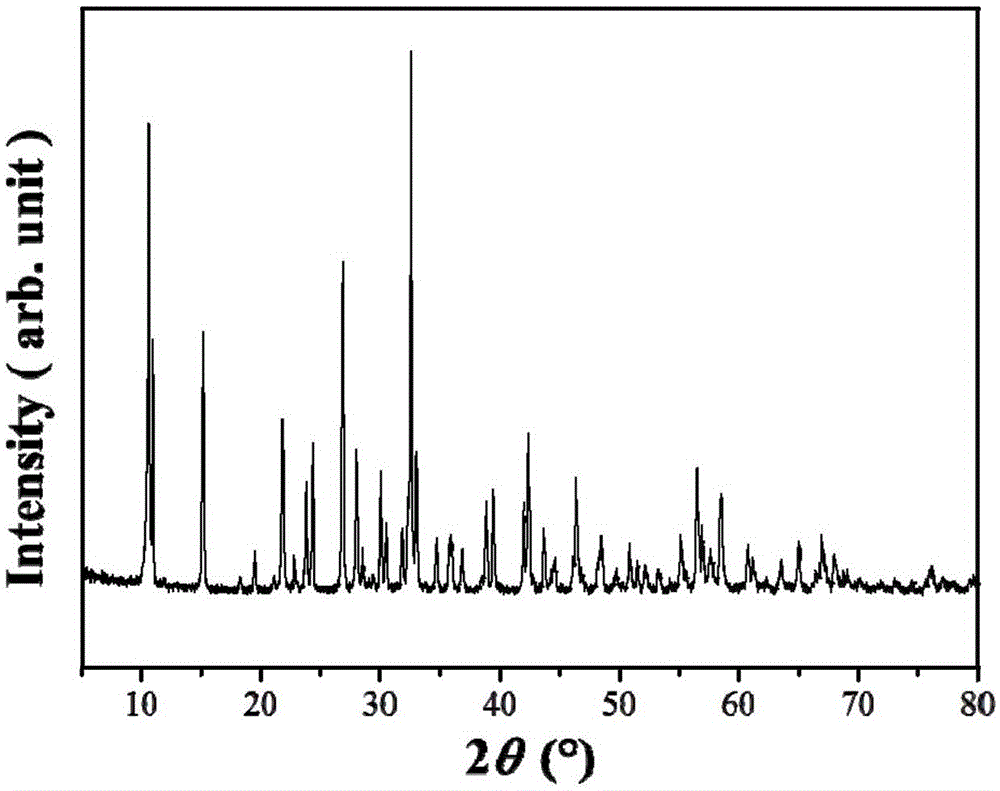

[0056] figure 1 , Figure 4 with Image 6 The X-ray diffraction patterns of the potassium sodium niobate crystalline hydrate prepared in Examples 1, 2 and 3 respectively. By comparison, the peak shapes of these three X-ray diffraction patterns are completely consistent, which shows that the crystal phases of potassium sodium niob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com