Wave plate design and error correction method in contrast ratio adjustable point diffraction interference system

A point diffraction interference and error correction technology, applied in the optical field, can solve the problems of reducing detection efficiency, large wavefront distortion aberration and polarization aberration, and increasing the complexity of installation and adjustment, so as to achieve simple system adjustment and reduce wavefront distortion. The effect of aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

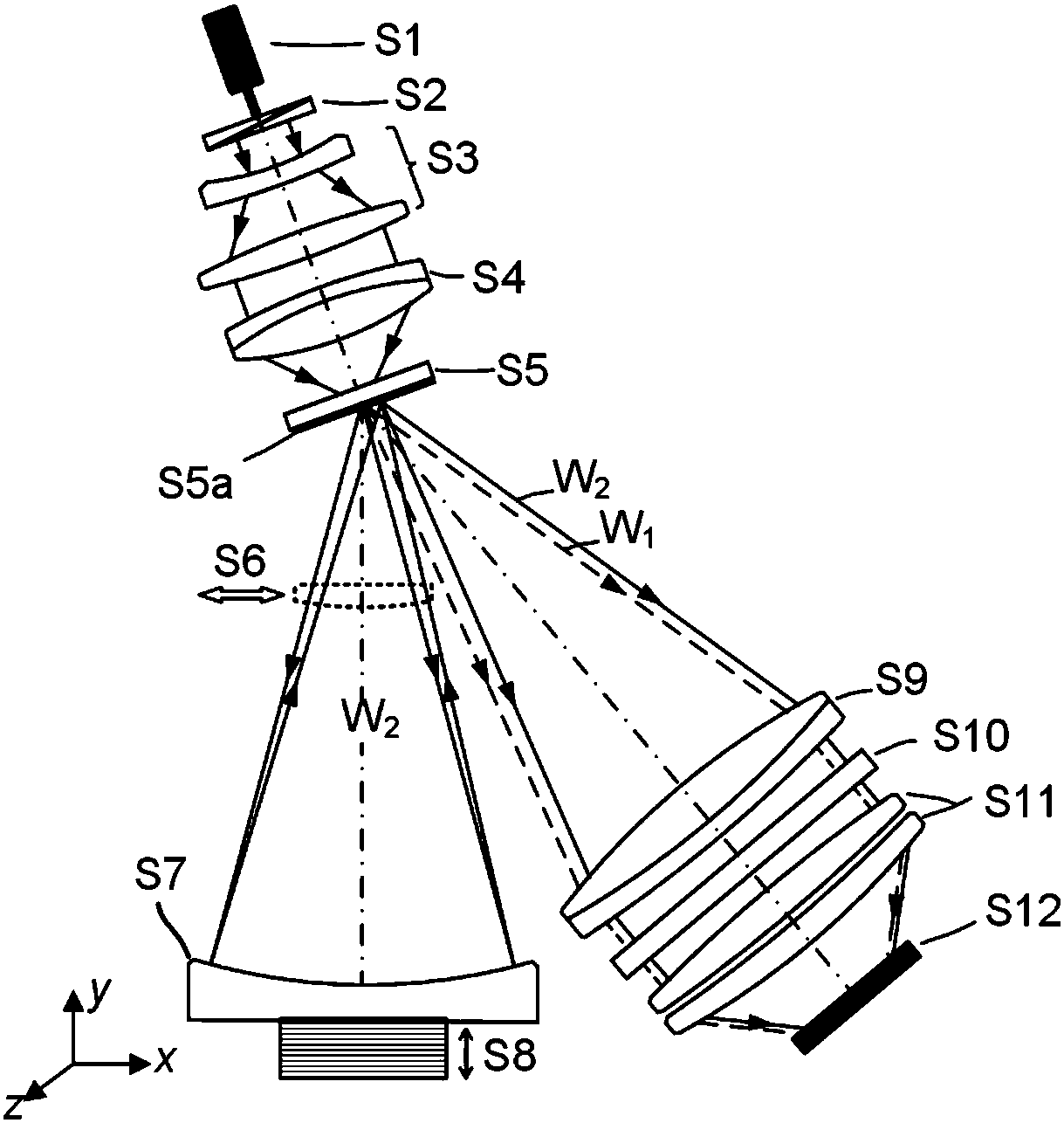

[0065] The present invention is applied to the design of an even-order aspheric quarter-wave plate in a contrast-adjustable point diffraction interference system and an example of an error correction method is described as follows.

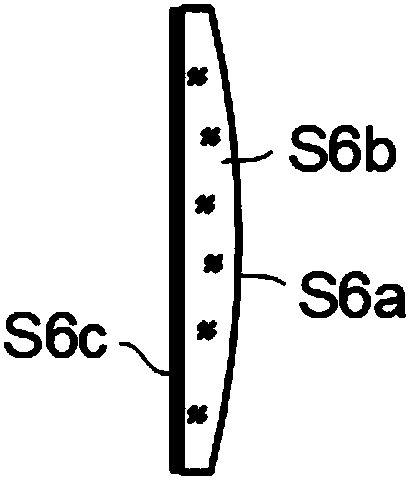

[0066] The wave plate is an even-order aspheric quarter-wave plate, and the even-order aspheric quarter-wave plate includes a plano-convex lens base whose convex surface is an even-order aspheric surface and a silicon dioxide polarizing film layer coated on the plane. The material of the plano-convex lens is K9 glass (refractive index n=1.51630), the center thickness is 1 mm, and the radius of curvature of the aspheric vertex is 500 mm.

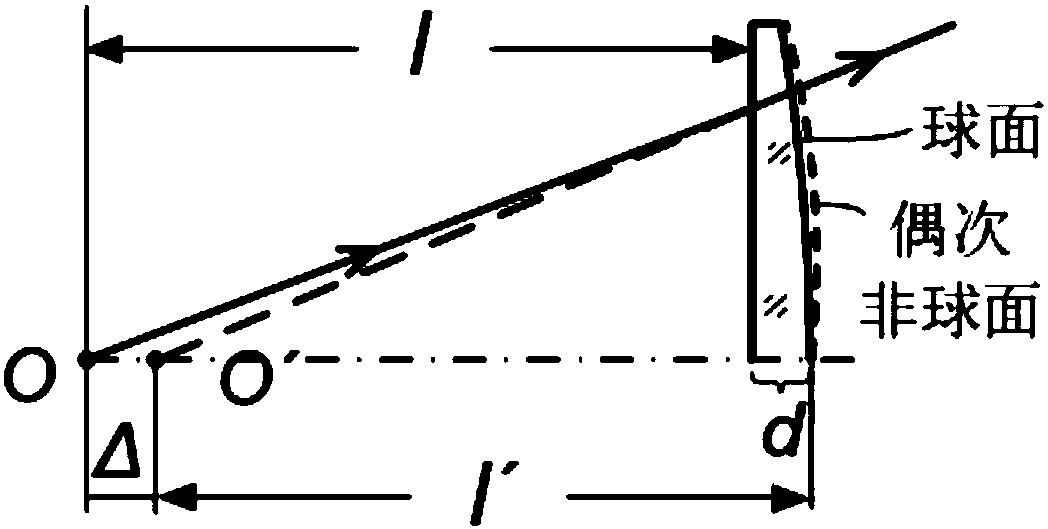

[0067] A ray tracing model was established to solve the structural parameters of the plano-convex lens substrate. First, the position of the image point after the paraxial light emitted by the pinhole passes through the base of the plano-convex lens is calculated by Gaussian formula. Since the pinhole diffractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com