Diamond window sealing device and fabrication method thereof

A technology of diamond and diamond film, which is applied in the manufacture of semiconductor devices, electrical components, and final products, etc., can solve the problems of difficult rework of the welding process, difficulty in sealing or encapsulating the main equipment, cracking of the sealing material, etc. The effect of reducing the difficulty of application, easy repair or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Spin-coat PMMA on the clean diamond surface, expose the PMMA on the edge of the diamond with an electron beam, and obtain a photoresist pattern after development, and the diamond at the edge is exposed.

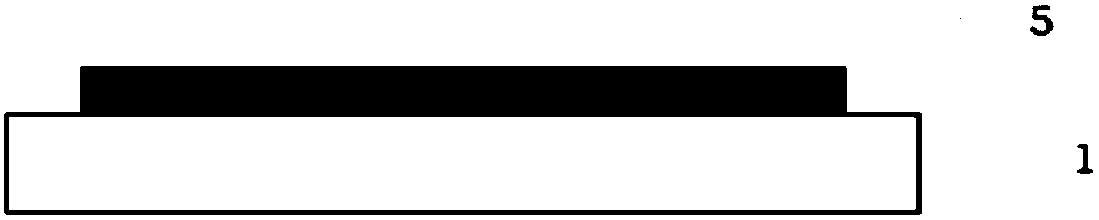

[0038] 2. Using electron beam evaporation method in figure 1 A layer of titanium metal was vapor-deposited on the upper surface of the sample shown, with a thickness of about 50 nm. The sample was soaked in acetone solution for 30 minutes, and the PMMA layer was removed to obtain a diamond window sample coated with metal titanium around the periphery.

[0039] Then bake at 500°C for 30 minutes in a vacuum or inert environment, so that the metal and diamond form a firm C-metal compound.

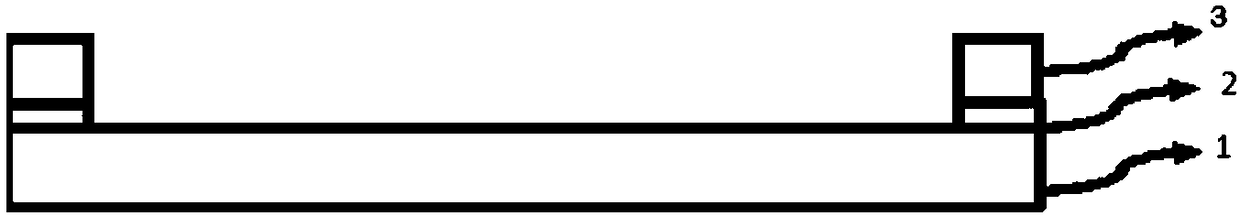

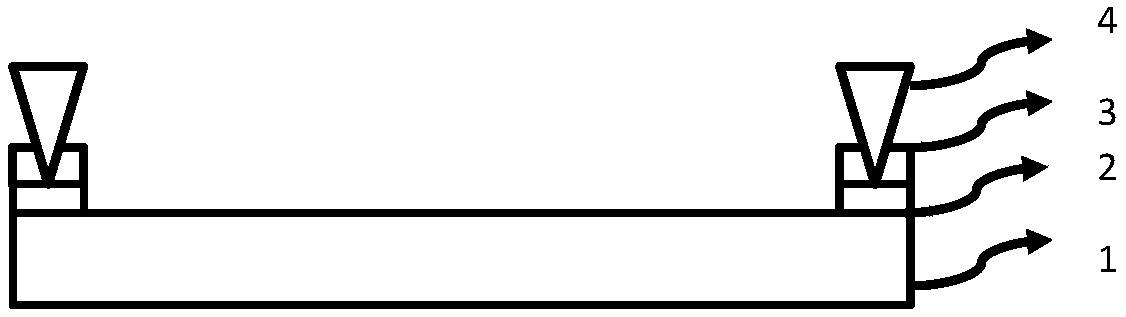

[0040] Then adopt the electroplating method to electroplate a layer of 2.5mm thick copper layer on the metal titanium layer, and polish the copper layer to obtain a diamond window sealing device with a copper layer thickness of about 2mm and a smooth and flat surface (such as figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com