A kind of treatment method of epoxy resin production wastewater

A technology for epoxy resin and waste water production, which is applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of shortening the service life of the evaporator, reducing the evaporation efficiency, and complex salt components, etc., and achieves enhanced fen The effect of the treatment effect, the removal load is high, and the treatment effect is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

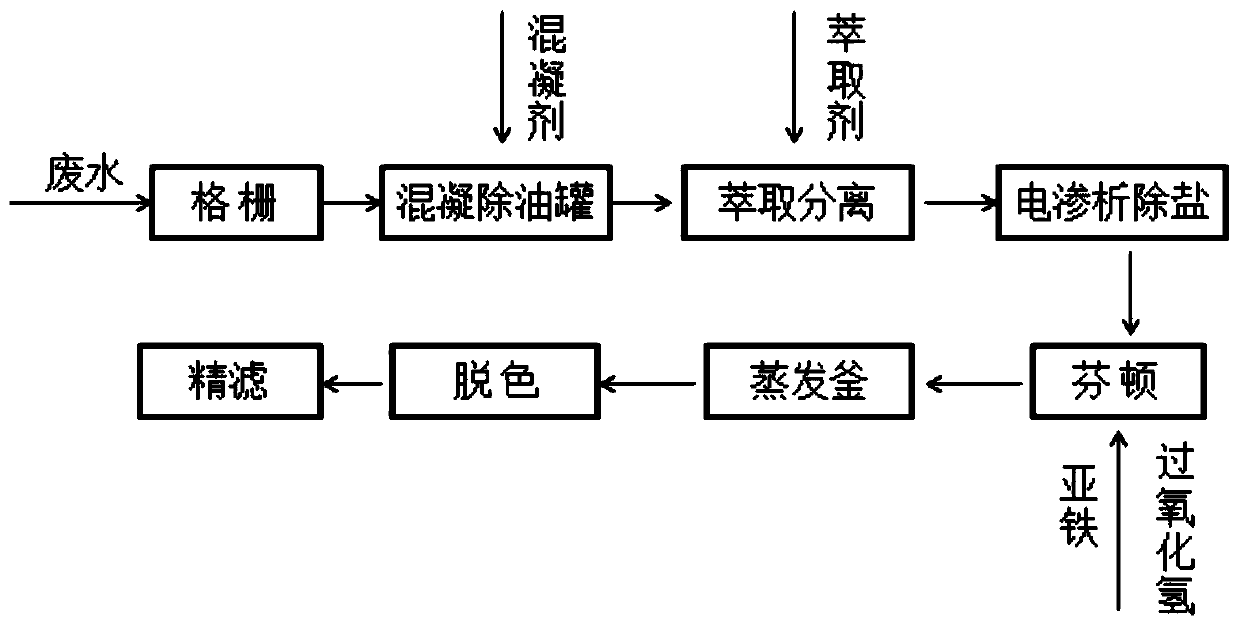

Image

Examples

Embodiment 1

[0024] The COD in the epoxy resin production wastewater to be treated is 3200mg / L, and the TOC is 2200mg / L.

[0025] The epoxy resin wastewater to be treated is removed by the grid to remove the large suspended impurities; the treated wastewater enters the coagulation degreasing tank for degreasing treatment, and ferrous chloride 5ml / L is added during the treatment process, and mixed in the pipeline. Then enter the oil removal tank through the water inlet pipe in a tangential direction to react, the reaction time is 5 minutes, and the residence time is 2 hours; after treatment, xylene extractant is added to the waste water, and the organic phase of the upper layer is extracted and separated and returned to the resin production process for recycling; After the treatment, the wastewater enters the electrodialysis desalination system for desalination treatment. The electrodialysis uses a 0.5mm separator; after the treatment, the wastewater is firstly added with hydrochloric acid t...

Embodiment 2

[0027] The COD in the epoxy resin production wastewater to be treated is 2500mg / L, and the TOC is 1800mg / L.

[0028] The epoxy resin wastewater to be treated is removed through the grid to remove the large suspended impurities; the treated wastewater enters the coagulation degreasing tank for degreasing treatment. During the treatment process, ferrous sulfate 5ml / L is added, mixed in the pipeline, and then Enter the oil removal tank in a tangential direction through the water inlet pipe for reaction, the reaction time is 7 minutes, and the residence time is 3 hours; after treatment, xylene extractant is added to the waste water, and the organic phase of the upper layer is extracted and separated and returned to the resin production process for recycling; treatment After the wastewater enters the electrodialysis desalination system for desalination treatment, the electrodialysis uses a 0.5mm separator; after the treatment, the wastewater is firstly added with hydrochloric acid t...

Embodiment 3

[0030] The COD in the epoxy resin production wastewater to be treated is 1000mg / L, and the TOC is 500mg / L.

[0031] The epoxy resin wastewater to be treated is removed through the grid to remove the large suspended impurities; the treated wastewater enters the coagulation degreasing tank for degreasing treatment. During the treatment process, ferrous sulfate 5ml / L is added, mixed in the pipeline, and then Enter the oil removal tank through the water inlet pipe in a tangential direction for reaction, the reaction time is 5 minutes, and the residence time is 2 hours; after treatment, xylene extractant is added to the waste water, and the organic phase of the upper layer is extracted and separated and returned to the resin production process for recycling; treatment After the wastewater enters the electrodialysis desalination system for desalination treatment, the electrodialysis uses a 0.5mm separator; after the treatment, the wastewater is firstly added with hydrochloric acid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com