Low-energy consumption and high-calorific value formed fuel processing device and method thereof

A technology for forming fuel and processing device, which is applied to fuels, solid fuels, biofuels, etc., can solve the problems of high volatile matter and ash content, and low calorific value, and achieves a reduction in the proportion of volatile matter, high calorific value, and low calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

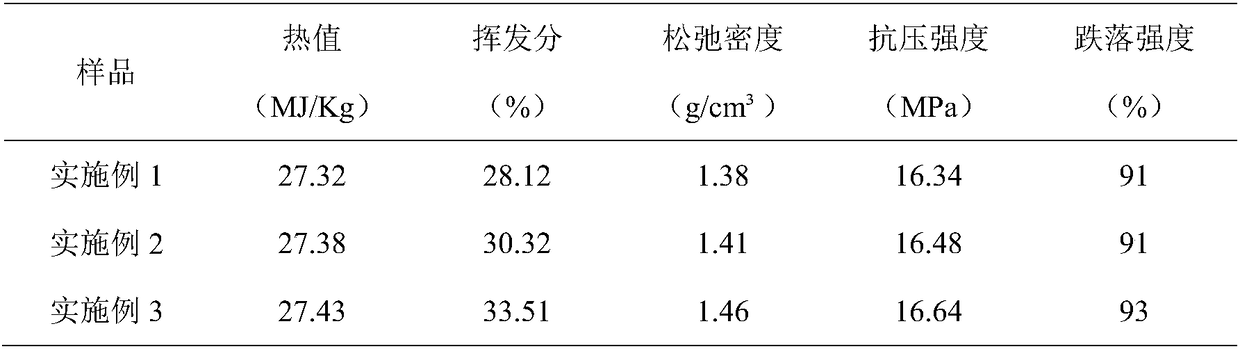

Embodiment 1

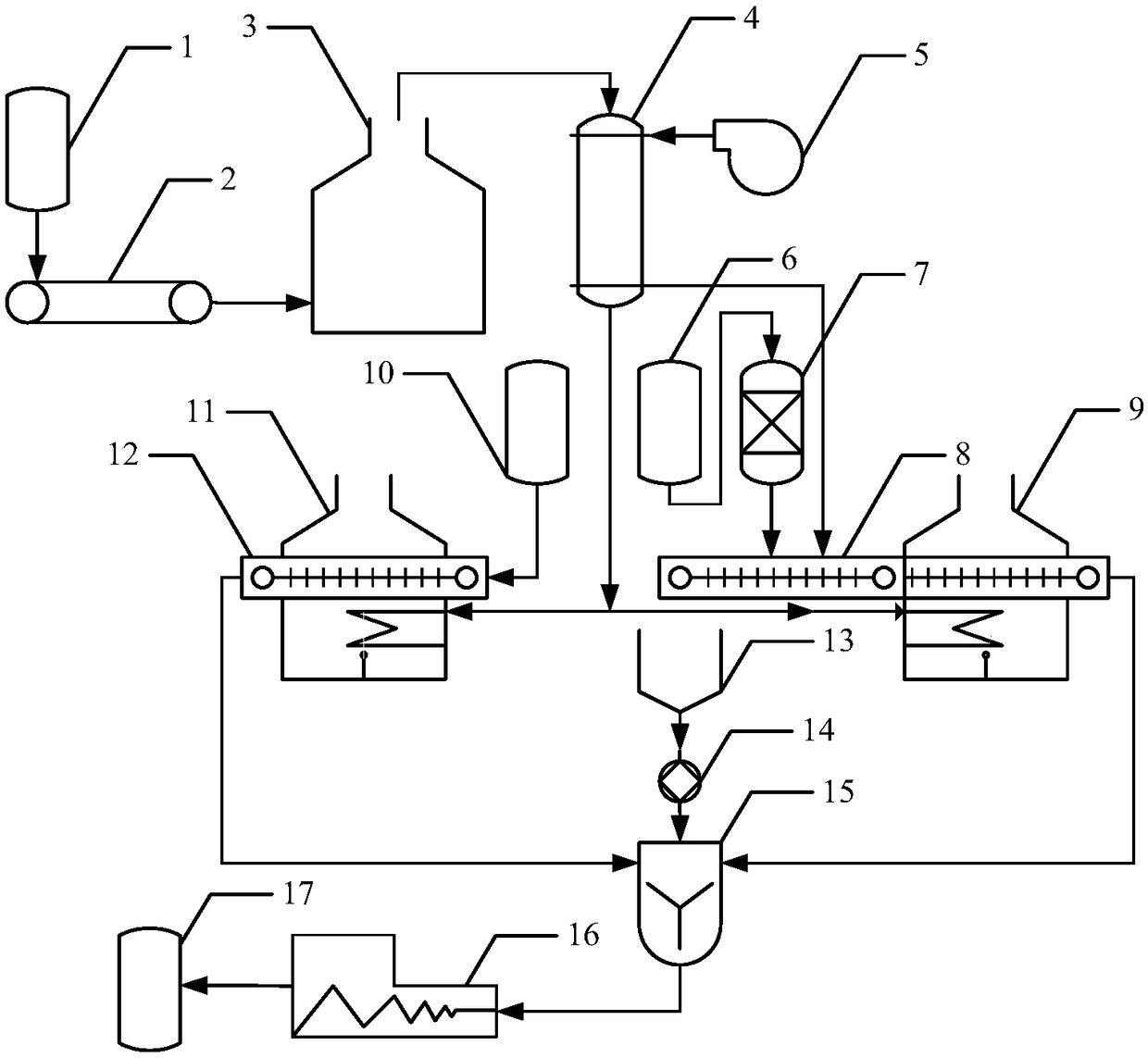

[0058] A method for processing biomass solid briquette fuel, the specific operation steps are as follows:

[0059] (1) Combustible gas preparation of wheat straw raw materials: process wheat straw raw materials into wheat straw powder with a particle size of 1-2mm, and fill them into the first-level straw storage bin and the second-level straw storage bin; store the first-level straw The wheat straw powder with a particle size of 1-2 mm in the warehouse is transported to the first biomass gasifier through the scraper conveyor, and the wheat straw powder is gasified by the first-stage straw storage warehouse to obtain combustible gas, and the combustible gas undergoes heat exchange through tubes The temperature of the device is lowered and sent to the first gas heating furnace and the second gas heating furnace;

[0060] Among them, the working conditions of the biomass gasifier are: the feed rate of straw powder is 1t / h, the gasification temperature core is 1000°C, the reactio...

Embodiment 2

[0071] A method for processing biomass solid briquette fuel, the specific operation steps are as follows:

[0072] (1) Combustible gas preparation of wheat straw raw materials: process wheat straw raw materials into wheat straw powder with a particle size of 1-2mm, and fill them into the first-level straw storage bin and the second-level straw storage bin; store the first-level straw The wheat straw powder with a particle size of 1-2 mm in the warehouse is transported to the first biomass gasifier through the scraper conveyor, and the wheat straw powder is gasified by the first-stage straw storage warehouse to obtain combustible gas, and the combustible gas undergoes heat exchange through tubes The temperature of the device is lowered and sent to the first gas heating furnace and the second gas heating furnace;

[0073] Among them, the working conditions of the biomass gasifier are: the feed rate of straw powder is 1t / h, the gasification temperature core is 1000°C, the reactio...

Embodiment 3

[0084] A method for processing biomass solid briquette fuel, the specific operation steps are as follows:

[0085] (1) Combustible gas preparation of wheat straw raw materials: process wheat straw raw materials into wheat straw powder with a particle size of 1-2mm, and fill them into the first-level straw storage bin and the second-level straw storage bin; store the first-level straw The wheat straw powder with a particle size of 1-2 mm in the warehouse is transported to the first biomass gasifier through the scraper conveyor, and the wheat straw powder is gasified by the first-stage straw storage warehouse to obtain combustible gas, and the combustible gas undergoes heat exchange through tubes The temperature of the device is lowered and sent to the first gas heating furnace and the second gas heating furnace;

[0086] Among them, the working conditions of the biomass gasifier are: the feed rate of straw powder is 1t / h, the gasification temperature core is 1000°C, the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com