N and S enriched dual-diameter mesoporous structural carbon carrier and preparation method and application thereof

A mesoporous structure and double-aperture technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems that the sulfur-loaded matrix cannot withstand the cycle and rate process, and the sulfur-loaded capacity is not high, and achieve fast ion and electron transfer channels , High areal sulfur loading and high areal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

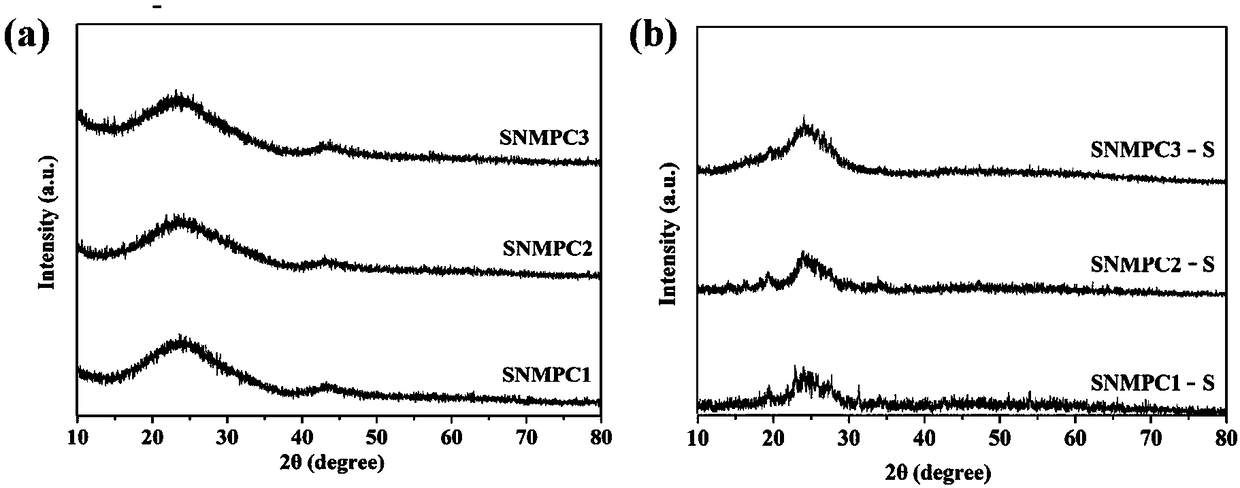

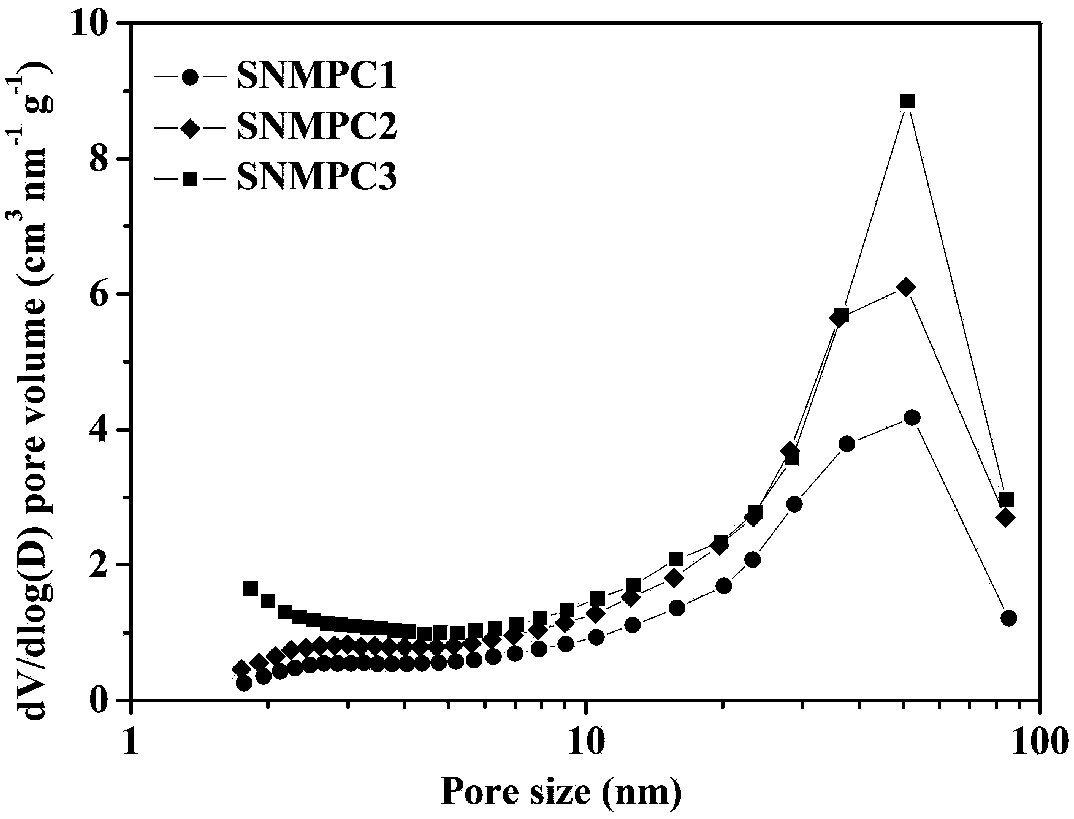

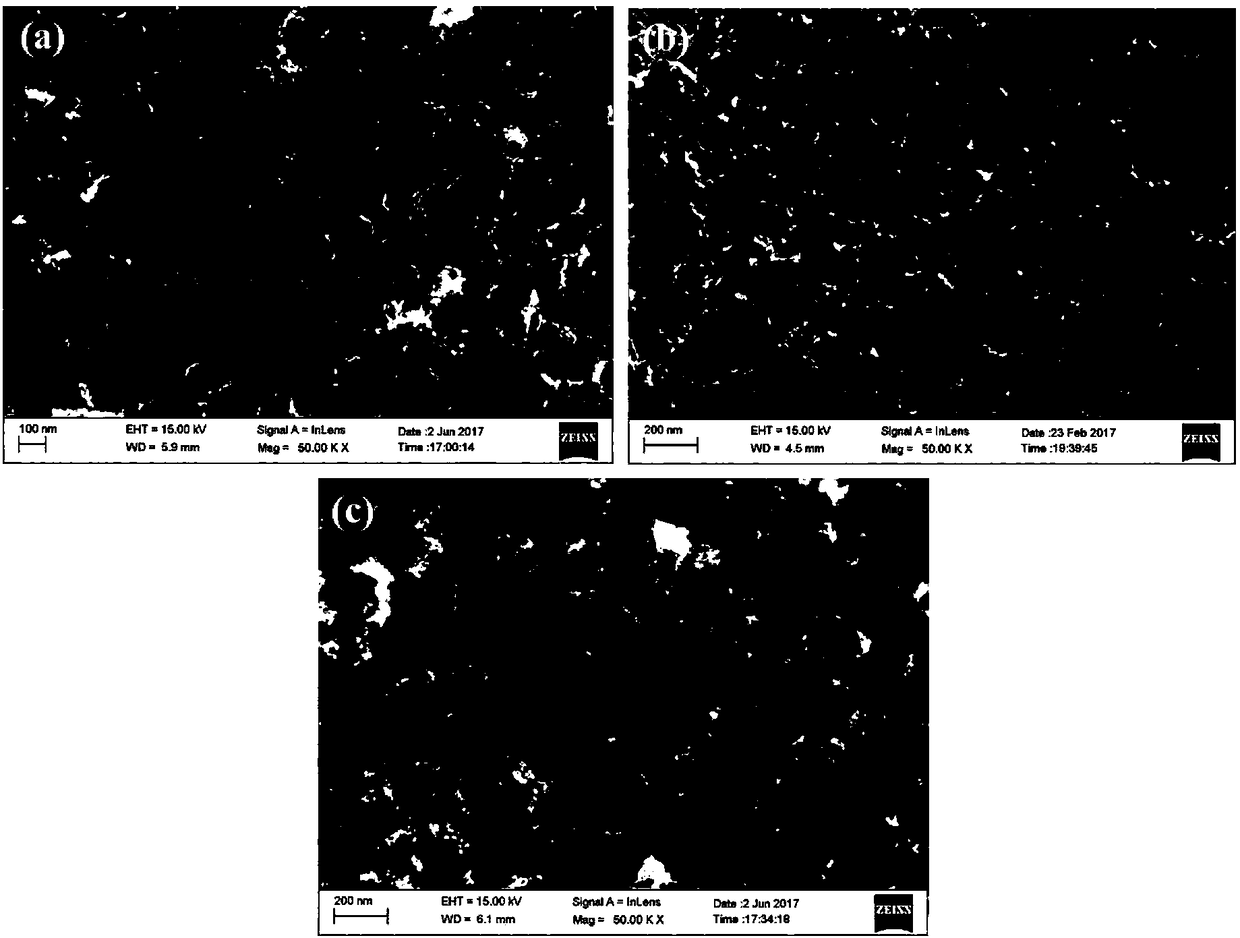

Embodiment 1

[0034] A carbon carrier with rich N and S dual-aperture mesoporous structure, with large pore volume and hierarchical mesoporous pores, the mesopore diameter is 30-60nm, the micropore diameter is 1.5-3nm, and the pore volume is 3.2cm 3 / g, the specific surface area is 791m 2 / g, wherein: the content of N and S elements is 4.18at% (atomic percentage content), the atomic ratio of C and S is 45.5:1, and the atomic ratio of C and N is 45:1.

[0035] The preparation of the above-mentioned N, S-rich double-aperture mesoporous structure carbon carrier (SNMPC) includes the following steps:

[0036] Mesoporous carbon as the basic carbon source, including disordered or ordered mesoporous carbon with single or double pore size;

[0037] Weigh 150 mg of mesoporous carbon and ultrasonically disperse it in deionized water, add 200 mg of zinc chloride and 100 mg of thiourea, mix well, place in a 160°C oven or low-temperature furnace for 7 hours, and obtain a semi-finished product;

[0038]...

Embodiment 2

[0043] A carbon carrier with rich N and S dual-aperture mesoporous structure, with large pore volume and hierarchical mesoporous pores. 3 / g, the specific surface area is 1420m 2 / g, wherein: the contents of N and S elements are both 4.25 at%, the atomic ratio of C and S is 45.5:1, and the atomic ratio of C and N is 45:1.

[0044] The preparation of the above-mentioned N, S-rich double-aperture mesoporous structure carbon support includes the following steps:

[0045] Mesoporous carbon as the basic carbon source, including disordered or ordered mesoporous carbon with single or double pore size;

[0046] Weigh 150 mg of mesoporous carbon and ultrasonically disperse it in deionized water, add 200 mg of zinc chloride and 200 mg of thiourea, mix well, and place in a 180°C oven or low-temperature furnace for 8 hours to obtain a semi-finished product;

[0047] The semi-finished product was heat-treated at 800°C for 2 hours under the protection of protective gas to obtain the finishe...

Embodiment 3

[0052] A carbon carrier with rich N and S dual-aperture mesoporous structure, with large pore volume and hierarchical mesoporous pores, the mesopore diameter is 30-60nm, the micropore diameter is 1.5-3nm, and the pore volume is 5.8cm 3 / g, the specific surface area is 1674m 2 / g, wherein: the contents of N and S elements are both 5.28 at%, the atomic ratio of C and S is 30:1, and the atomic ratio of C and N is 45:1.

[0053] The preparation of the above-mentioned N, S-rich double-aperture mesoporous structure carbon support includes the following steps:

[0054] Mesoporous carbon as the basic carbon source, including disordered or ordered mesoporous carbon with single or double pore size;

[0055] Weigh 150 mg of mesoporous carbon and ultrasonically disperse it in deionized water, add 200 mg of zinc chloride and 300 mg of thiourea, mix well, place in a 190°C oven or low-temperature furnace for 6 hours, and obtain a semi-finished product;

[0056] The semi-finished product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com