Large-flux hydrophilic oleophobic oil-water separation membrane with antibacterial function as well as preparation and application of membrane

A technology of oil, oil and water, which is applied in the field of hydrophilic, oil-repellent, oil-water separation membrane and its preparation, which can solve the problems of environmental and biological hazards, the inability to improve membrane flux, etc., and achieve the advantages of increased strength, increased speed, and strong bactericidal ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

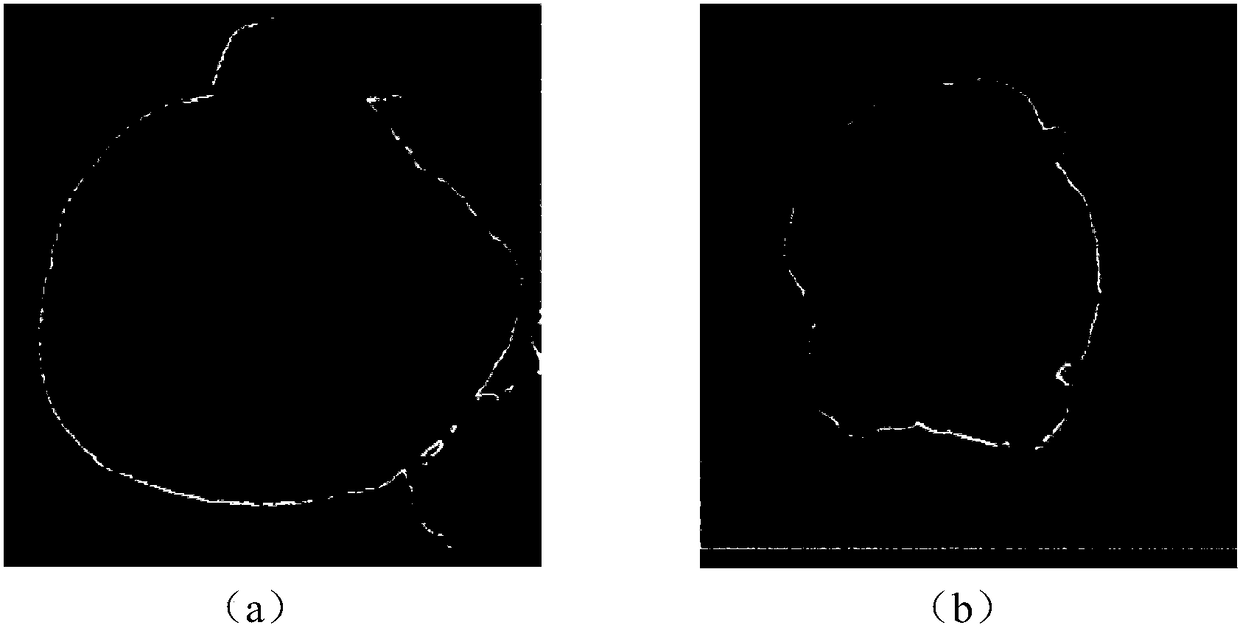

Examples

Embodiment 1

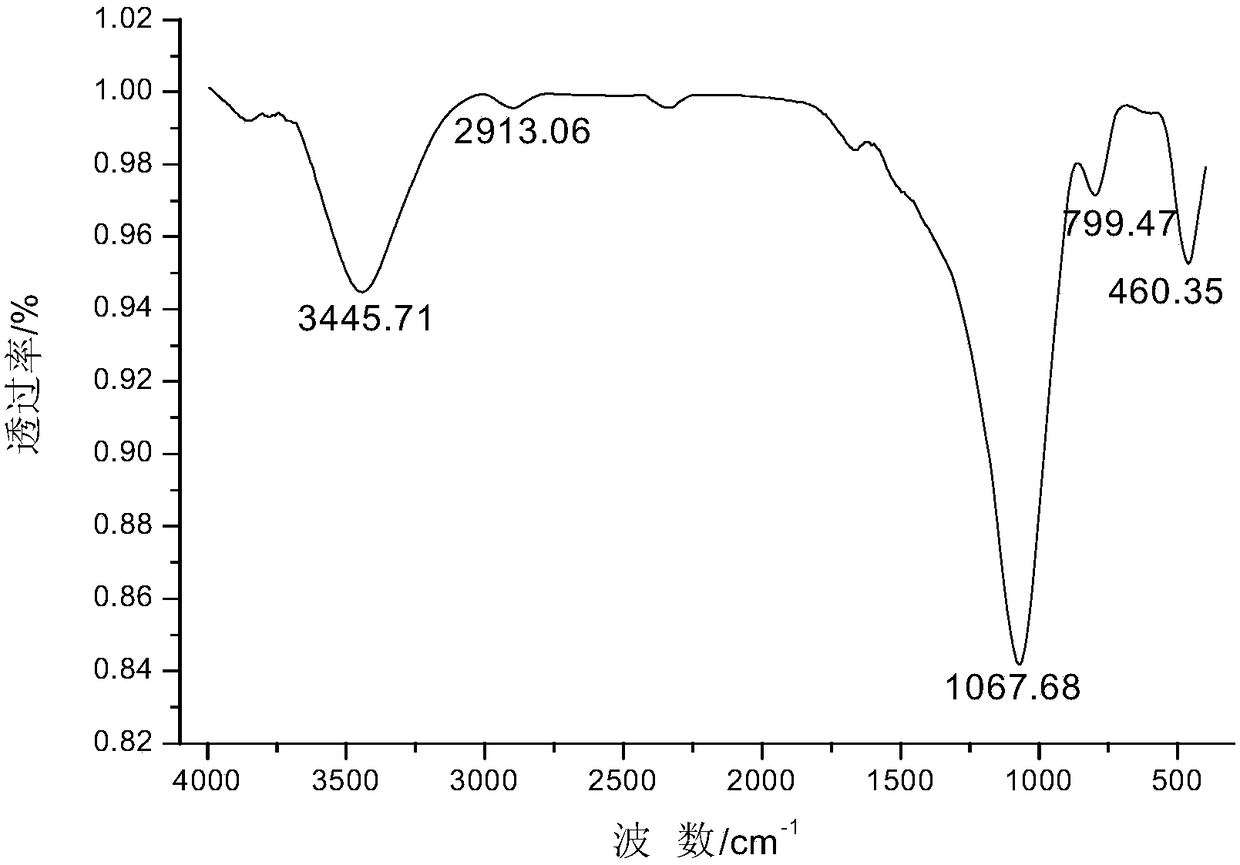

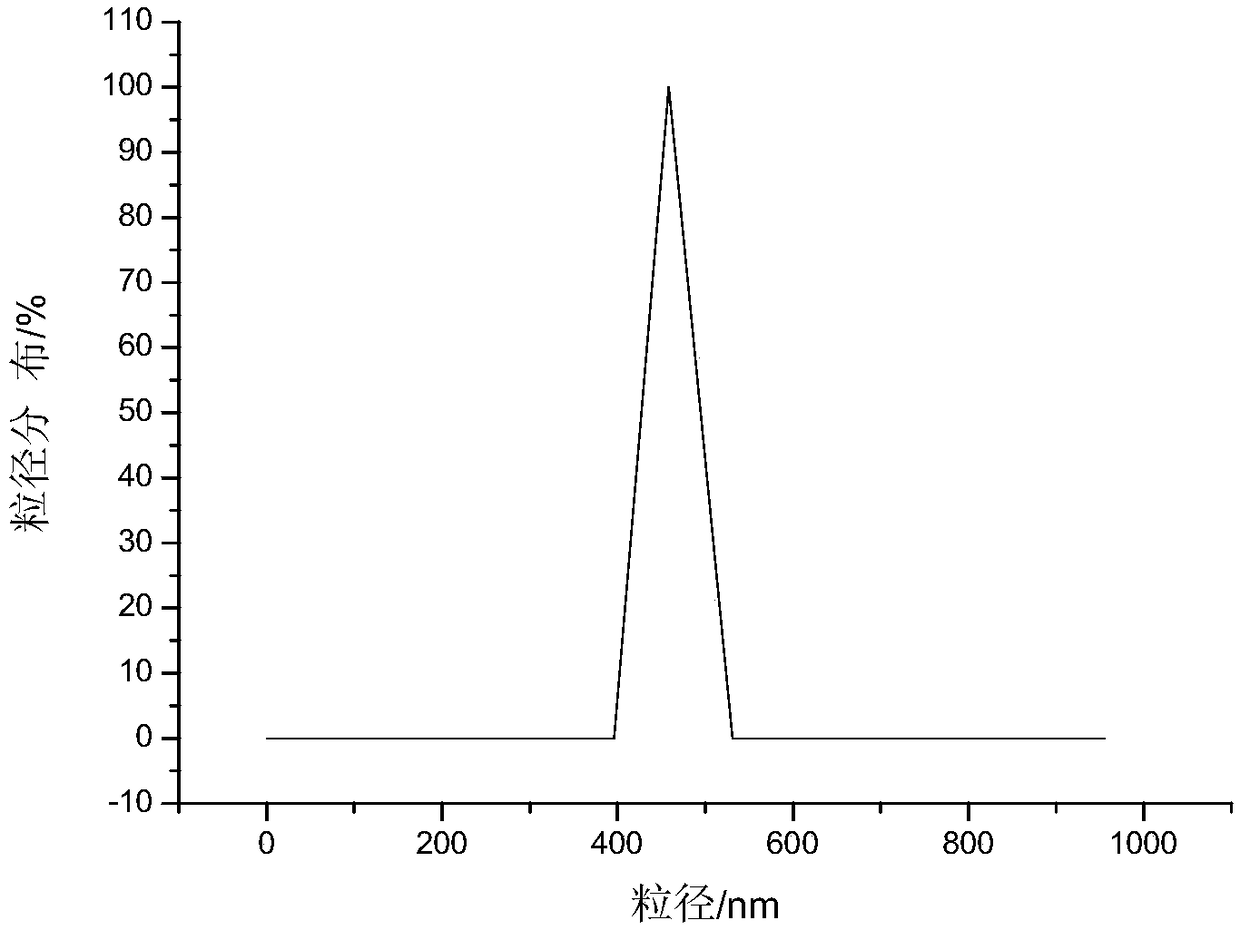

[0056] (1) Synthesis of porous nano silica:

[0057] (1-1) Add 0.5g of porogen CTAB and 0.14g of catalyst NaOH into the reaction vessel, add 240mL of deionized water, and stir at 80°C (500r / min) for 1h. After the system in the vessel becomes homogeneous, Slowly pour 2.5mL of silicon source TEOS into the constant flow pump in 30min, keep it warm for 2h after dripping, and form a white suspension; the molar ratio of each material is TEOS:NaOH:CTAB=1:0.3:0.2;

[0058] (1-2) Filter the resulting white suspension with a vacuum filter, then wash the resulting solid with deionized water, then put it in a 60°C oven and dry it for 12 hours, then put it in a muffle furnace for calcination ( From room temperature to 650°C at a rate of 2°C / min, and kept at this temperature for 6h), the porous SiO 2 (i.e. porous nano-silica);

[0059] (2) Modification of porous nano silica

[0060] (2-1) Drying the porous nano silica in a vacuum oven at 100°C for 24 hours;

[0061] (2-2) Ultrasonically...

Embodiment 2

[0078] (1) Synthesis of porous silica particles:

[0079] (1-1) 1.0g porogen CTAB and 0.2g catalyst NH 3 ·H 2 O (mass concentration in aqueous solution: 25%) was added to the reaction vessel, 240mL of deionized water was added, and stirred at a constant temperature of 85°C (480r / min) for 1h. Add 2.5mL of silicon source TEOS, keep it warm for 2h after dripping, and generate a white suspension; the molar ratio of each material is TEOS:NH 3 ·H 2 O:CTAB=1:0.5:0.4;

[0080] (1-2) Filter the resulting white suspension with a vacuum filter, then wash the resulting solid with deionized water, then put it in a 60°C oven and dry it for 12 hours, then put it in a muffle furnace for calcination ( From room temperature to 650°C at a rate of 2°C / min, and kept at this temperature for 6h), the porous SiO 2 (i.e. porous nano-silica);

[0081] (2) Modification of porous nano silica

[0082] (2-1) Drying the porous nano silica in a vacuum oven at 100°C for 24 hours;

[0083] (2-2) Ultras...

Embodiment 3

[0093] (1) Synthesis of porous silica particles:

[0094] (1-1) 2.5g porogen PEG2000 and 0.2g catalyst NH 3 ·H 2 O (mass concentration 25%) was added to the reaction vessel, 240mL of deionized water was added, stirred at 85°C (500r / min) for 1h, and after the system in the vessel became homogeneous, 2.5 mL of silicon source TEOS, keep it warm for 1 hour after dripping to form a white suspension; the molar ratio of each material is TEOS:NH 3 ·H 2 O: PEG2000 = 1:0.5:0.1;

[0095] (1-2) Filter the resulting white suspension with a vacuum filter, then wash the resulting solid with deionized water, then put it in a 60°C oven and dry it for 12 hours, then put it in a muffle furnace for calcination ( From room temperature to 650°C at a rate of 2°C / min, and kept at this temperature for 6h), the porous SiO 2 (i.e. porous nano-silica);

[0096] (2) Modification of porous nano silica

[0097] (2-1) Drying the porous nano silica in a vacuum oven at 100°C for 24 hours;

[0098] (2-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com