Engineering surface for improving underwater bubble locking capacity and preparation method thereof

A bubble-capable, super-hydrophobic surface technology, applied in special surfaces, pre-treatment surfaces, devices for coating liquids on surfaces, etc., can solve the problems of loss of super-hydrophobic properties, easy loss of underwater bubbles, etc., and achieve stable super-hydrophobic properties , The preparation process is simple and easy to implement, and the practicability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The construction method of the superhydrophobic / superhydrophilic array surface of the present invention that can greatly improve the ability to "lock" bubbles underwater is as follows:

[0027] The first step is to use aluminum alloy as the base material, wire-cut it into a size of 10cm×10cm×1mm, use No. 1 to No. 6 metallographic sandpaper to polish the surface of the aluminum alloy, and then ultrasonically in acetone, absolute ethanol and deionized water After washing for 15 minutes, dry it for later use;

[0028] In the second step, using the electrochemical etching method, the aluminum sheet is used as the anode, the platinum sheet is used as the cathode, the NaCl electrolyte concentration is 0.1mol / L, the voltage is 6V, and the etching time is 2h to obtain a microstructure on the surface of the substrate.

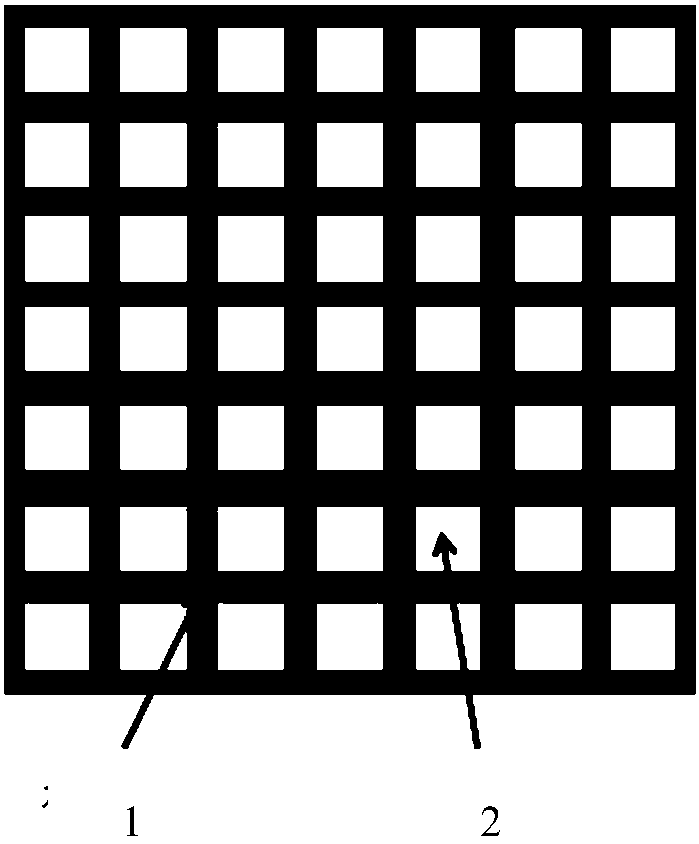

[0029] In the third step, the superhydrophobic shape of the design unit is a square with a side length of 1cm, and the distance between each square is 0.2cm. Wa...

Embodiment 2

[0033] The construction method of the superhydrophobic / superhydrophilic array surface of the present invention that can greatly improve the ability to "lock" bubbles underwater is as follows:

[0034] The first step is to use aluminum alloy as the base material, wire-cut it into a size of 10cm×10cm×1mm, use No. 1 to No. 6 metallographic sandpaper to polish the surface of the aluminum alloy, and then ultrasonically in acetone, absolute ethanol and deionized water After washing for 20 minutes, dry it for later use;

[0035] In the second step, using the electrochemical etching method, the aluminum sheet is used as the anode, the platinum sheet is used as the cathode, the NaCl electrolyte concentration is 0.1mol / L, the voltage is 6V, and the etching time is 2h to obtain a microstructure on the surface of the substrate.

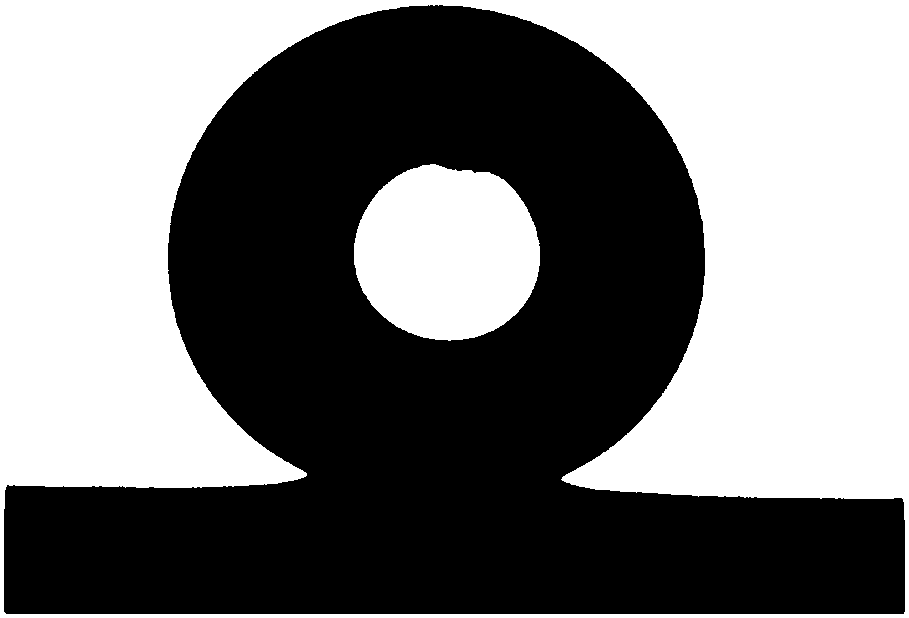

[0036] In the third step, the super-hydrophobic shape of the design unit is a circle with a diameter of 1 cm, and the distance between the centers of two adjacen...

Embodiment 3

[0040] The construction method of the superhydrophobic / superhydrophilic array surface of the present invention that can greatly improve the ability to "lock" bubbles underwater is as follows:

[0041] The first step is to use aluminum alloy as the base material, wire-cut it into a size of 10cm×10cm×1mm, use No. 1 to No. 6 metallographic sandpaper to polish the surface of the aluminum alloy, and then ultrasonically in acetone, absolute ethanol and deionized water After washing for 10 minutes, dry it for later use;

[0042] The second step is to use the method of electrochemical etching, using the aluminum sheet as the anode and the platinum sheet as the cathode, the concentration of the NaCl electrolyte is 0.1mol / L, the voltage is 8V, and the etching time is 2h to obtain the microstructure on the surface of the substrate.

[0043]In the third step, the super-hydrophobic shape of the design unit is a circle with a diameter of 1 cm, and the distance between the centers of two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com