Preparation method of plastic scintillator optical fiber array

A technology of plastic scintillator and optical fiber array, which is applied in the direction of optical components, other household appliances, household appliances, etc., can solve the problems of light collection coefficient reduction, decline, and scintillator detector’s response ability to low-energy neutrons, etc., to achieve convenient The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

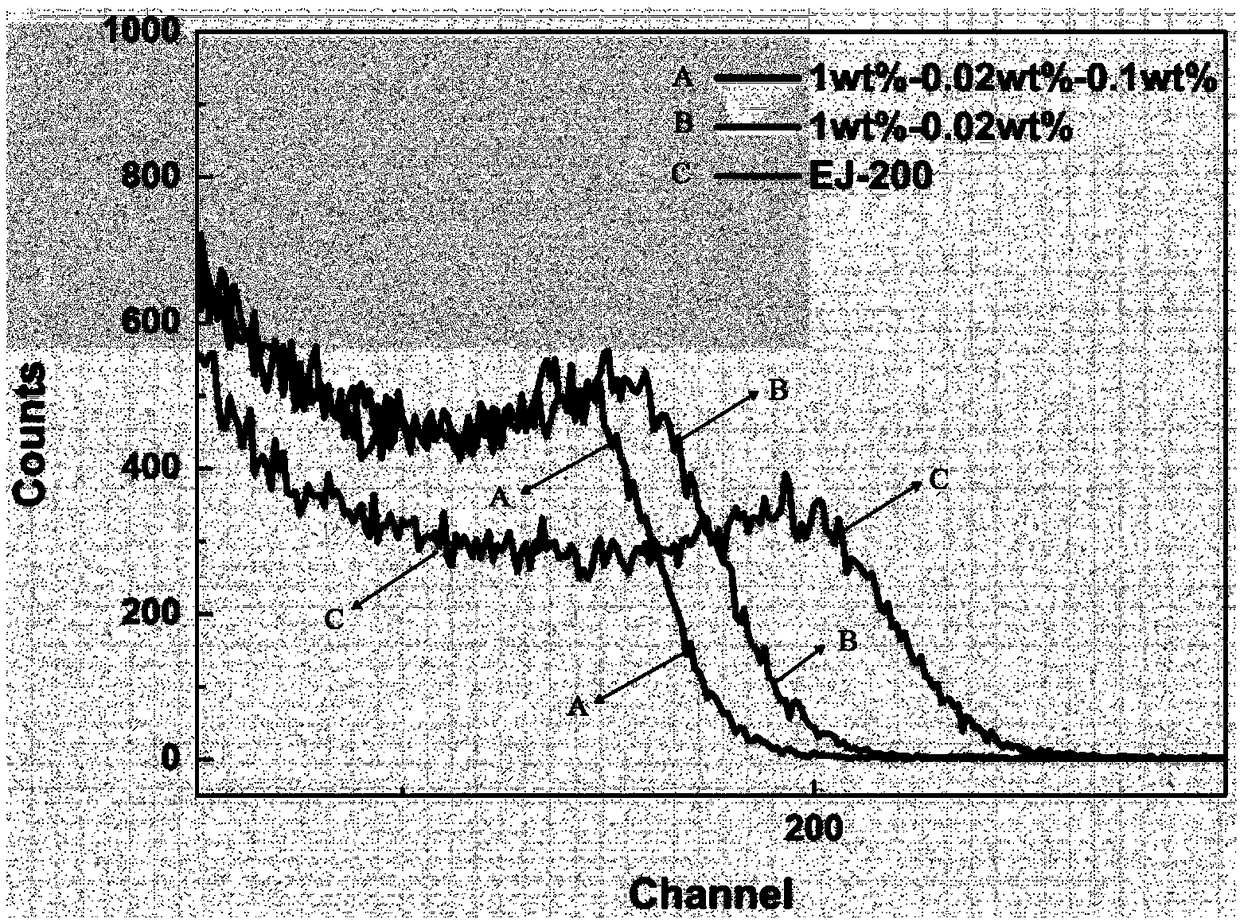

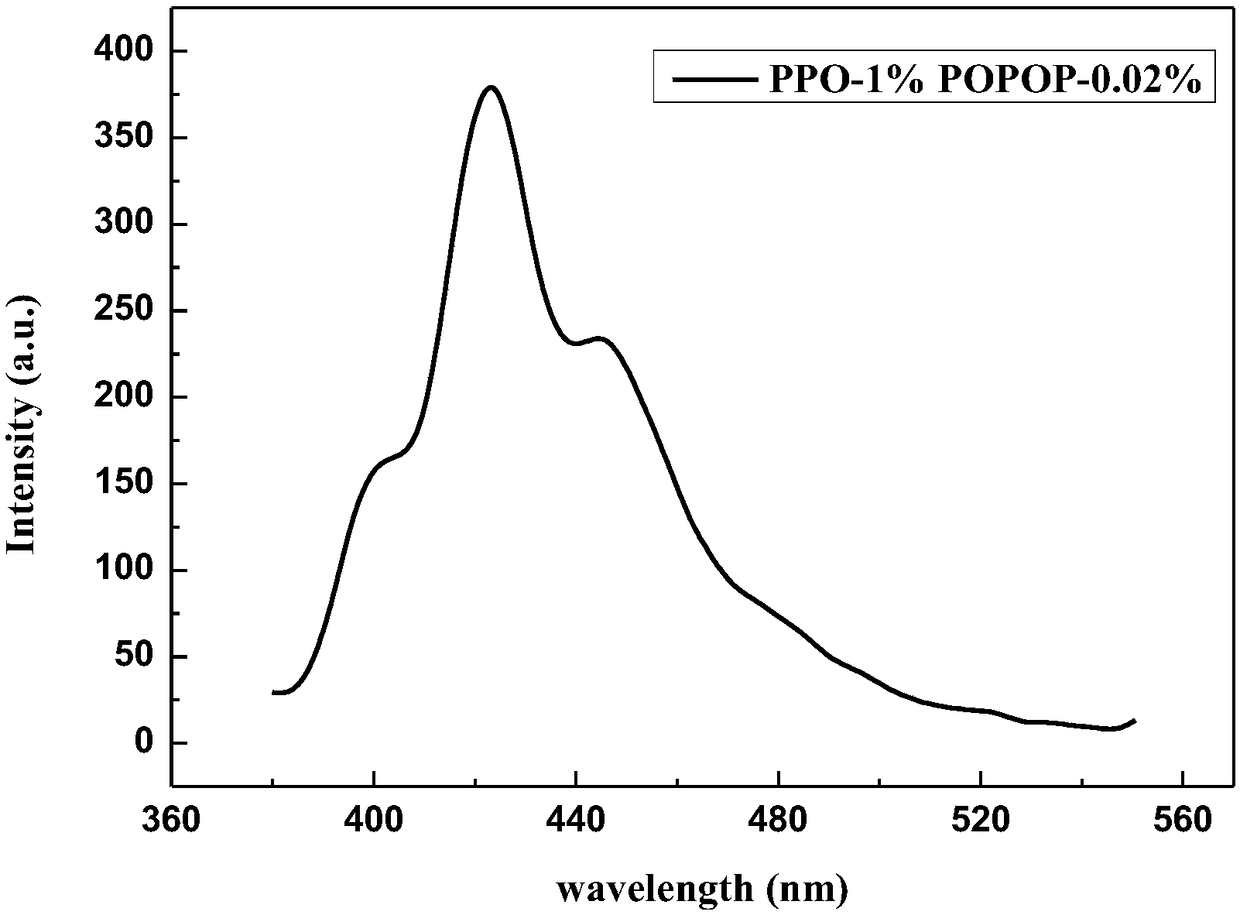

[0031] Prepare a plastic scintillator optical fiber with a mass fraction of 2,5-diphenyloxazole of 1 wt%, and a mass fraction of 1,4-bis[2-(5-phenyl)oxazolyl] of 0.02 wt%, and its array:

[0032] Step 1, measure 10g styrene, 0.1g 2,5-diphenyloxazole (PPO) and 0.002g 1,4-bis[2-(5-phenyl)oxazolyl]benzene (POPOP), in Fully mix in a nitrogen protective atmosphere, and stir for 90 minutes; obtain a sealed mixed solution;

[0033] Step 2. Place the sealed mixed solution in a 70°C incubator, and conduct the polymerization reaction for 48 hours in the first stage;

[0034] Step 3. Place the product of the first-stage polymerization reaction in a programmable temperature-controlled heating furnace, raise the temperature to 110°C, and the temperature rise rate is 5°C / h, and the second-stage polymerization reaction lasts for 120 hours;

[0035] Step 4. Place the product that completed the second-stage polymerization reaction in a 45°C incubator, and conduct the third-stage polymerizatio...

Embodiment 2

[0040]Prepare a plastic scintillator optical fiber with a mass fraction of 2,5-diphenyloxazole of 0.5wt% and a mass fraction of 1,4-bis[2-(5-phenyl)oxazolyl] of 0.02wt% and its array:

[0041] Step 1. Measure 10g of styrene, 0.05g of 2,5-diphenyloxazole and 0.002g of 1,4-bis[2-(5-phenyl)oxazolyl]benzene, fully mix them in a nitrogen protective atmosphere, and stir 90min, obtain the sealed mixed solution;

[0042] Step 2. Place the sealed mixed solution in a 70°C incubator, and conduct the polymerization reaction for 48 hours in the first stage;

[0043] Step 3. Place the product of the first-stage polymerization reaction in a programmable temperature-controlled heating furnace, raise the temperature to 110°C, and the temperature rise rate is 5°C / h, and the second-stage polymerization reaction lasts for 120 hours;

[0044] Step 4. Place the product that completed the second-stage polymerization reaction in a 45°C incubator, and conduct the third-stage polymerization reaction f...

Embodiment 3

[0049] Prepare a plastic scintillator optical fiber with a mass fraction of 2,5-diphenyloxazole of 2.5wt% and a mass fraction of 1,4-bis[2-(5-phenyl)oxazolyl] of 0.02wt% and its array:

[0050] Step 1. Measure 10g of styrene, 0.25g of 2,5-diphenyloxazole and 0.002g of 1,4-bis[2-(5-phenyl)oxazolyl]benzene, fully mix them in a nitrogen atmosphere, and stir 90min, obtain the sealed mixed solution;

[0051] Step 2. Place the sealed mixed solution in a 70°C incubator, and conduct the polymerization reaction for 48 hours in the first stage;

[0052] Step 3. Place the product of the first-stage polymerization reaction in a programmable temperature-controlled heating furnace, raise the temperature to 110°C, and the temperature rise rate is 5°C / h, and the second-stage polymerization reaction lasts for 120 hours;

[0053] Step 4. Place the product that completed the second-stage polymerization reaction in a 45°C incubator, and conduct the third-stage polymerization reaction for 72 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fine particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com