Purification rectifying tower and purification method for 3-methyl-3-butene-1-alcohol

A rectification tower and butene technology, which is applied in the field of purification methods and devices, can solve problems such as equipment blockage, yield drop, and solvent pyrolysis, and achieve the effects of inhibiting self-polymerization, simple structure, and reducing decomposition loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

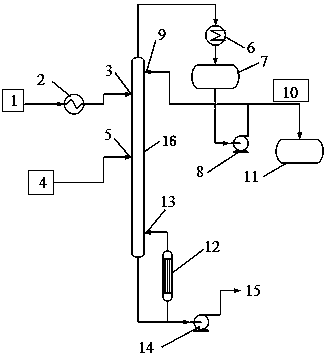

[0024] Examples, such as figure 1 Shown, a kind of purification rectification tower that is used for 3-methyl-3-butene-1-alcohol comprises rectification tower tower body 16, and the middle part of rectification tower tower body 16 has raw material inlet 5, rectification tower A solvent inlet 3 is provided near the tower top on the tower body 16, a solvent heater 2 is connected to the solvent inlet 3 through a pipeline, and a tower bottom pipeline is provided at the bottom of the tower body 16 of the rectification tower, and a still tank is connected to the tower bottom pipeline. Liquid pump 14, gas phase inlet 13 is provided at the bottom of rectification tower body 16, tower bottom heater 12 is also connected on the tower bottom pipeline of rectification tower tower body 16, and one end of tower bottom heater 12 is connected with tower bottom pipeline , the other end of the tower bottom heater 12 is connected with the gas phase inlet 13, the top of the rectifying tower body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com