High-gloss and high-impact-resistance ASA/PMMA (Acrylonitrile Styrene Acrylate/Polymethyl Methacrylate) material for automobile and preparation method thereof

A high-impact, high-gloss technology, which is used in the preparation of high-gloss and high-impact automotive ASA/PMMA materials and high-gloss and high-impact automotive ASA/PMMA materials, can solve the problem of poor impact performance and low cost. , the problem of low gloss of the material, to achieve the effect of improving the compatibility effect, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

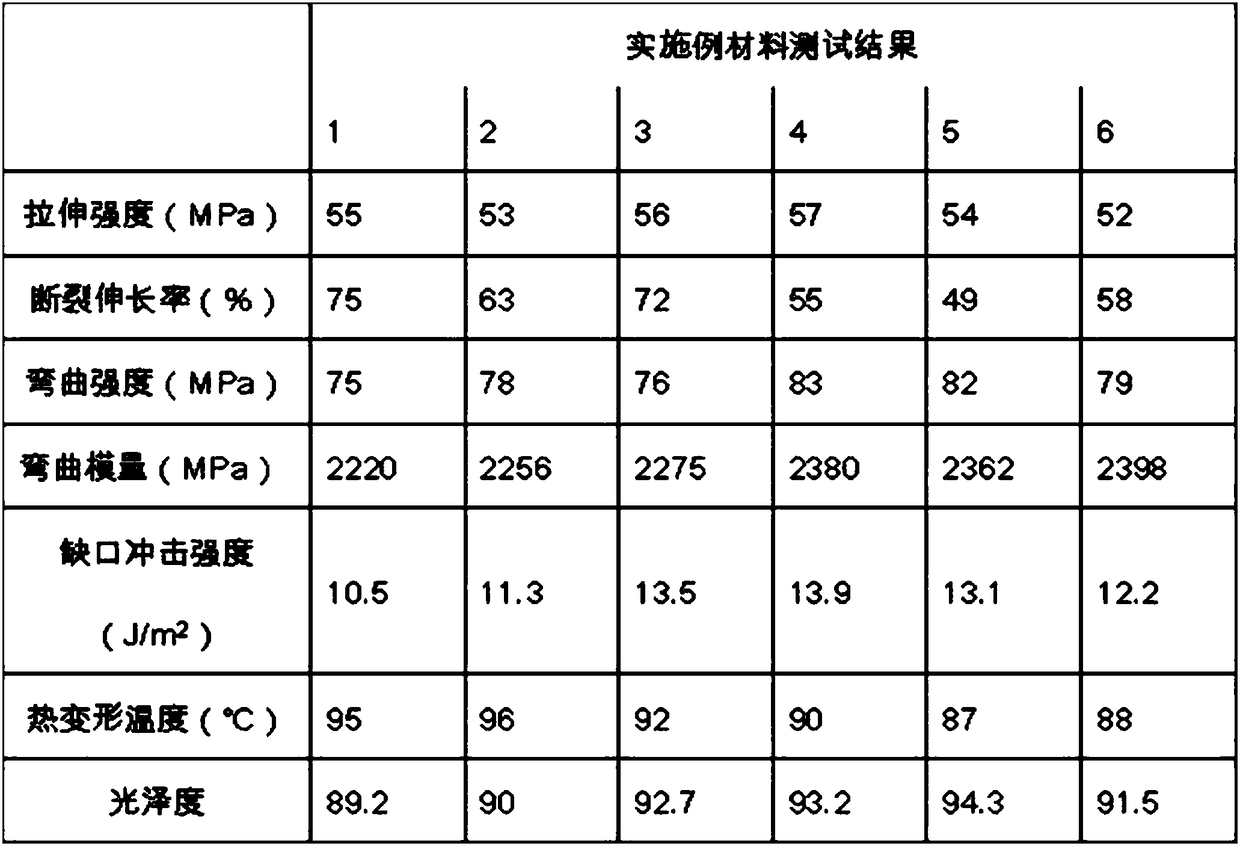

Examples

Embodiment 1

[0026] A preparation method of ASA / PMMA material for high-gloss and high-impact automobiles, comprising the following steps:

[0027] (1) 100 parts of ASA (weight-average molecular mass is 100000g / mol, acrylate percentage content 15%) is taken by weighing; PMMA (weight-average molecular mass is 150000g / mol) 50 parts; Maleic anhydride (mass Percent purity greater than or equal to 99.5%) 5 parts; Dicumyl peroxide 5 parts; 2,4-dichlorobenzoyl peroxide 3 parts; Methyl methacrylate-butadiene-styrene terpolymer 20 Parts; tetrakis-[β-(3.2-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010) 0.25 parts; three (2,4-di-tert-butyl) phenyl phosphite (Antioxidant 168) 0.25 parts; Halogen-free high gloss grease black pigment 0.5 parts. Mix ASA, PMMA, maleic anhydride, 2,4-dichlorobenzoyl peroxide and methyl methacrylate-butadiene-styrene terpolymer for 5 minutes until the appearance is uniform; Cumene, Antioxidant 1010, Antioxidant 168 and Halogen-free high-...

Embodiment 2

[0030] A preparation method of ASA / PMMA material for high-gloss and high-impact automobiles, comprising the following steps:

[0031] (1) 100 parts of ASA (weight-average molecular mass is 300000g / mol, acrylate percentage content 25%) is taken by weighing; PMMA (weight-average relative molecular mass is 100000g / mol) 60 parts; Maleic anhydride (mass Percent purity greater than or equal to 99.5%) 2 parts; dicumyl peroxide 12 parts; 2,4-dichlorobenzoyl peroxide 5 parts; methyl methacrylate-butadiene-styrene terpolymer 15 parts Parts; Tetrakis-[β-(3.2-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (Antioxidant 1010) 0.5 part; Tris(2,4-di-tert-butyl)phenyl phosphite (Antioxidant 168) 0.5 part; Halogen-free high gloss grease black pigment 1 part. Mix ASA, PMMA, maleic anhydride, 2,4-dichlorobenzoyl peroxide and methyl methacrylate-butadiene-styrene terpolymer for 4 minutes until the appearance is uniform; add di Cumene, Antioxidant 1010, Antioxidant 168 and Halog...

Embodiment 3

[0034] A preparation method of ASA / PMMA material for high-gloss and high-impact automobiles, comprising the following steps:

[0035](1) take by weighing 100 parts of ASA (weight-average molecular mass is 500000g / mol, acrylate percentage content 70%); PMMA (weight-average relative molecular mass is 50000g / mol) 40 parts; Maleic anhydride (mass Percent purity greater than or equal to 99.5%) 8 parts; 8 parts of dicumyl peroxide; 8 parts of 2,4-dichlorobenzoyl peroxide; 10 parts of methyl methacrylate-butadiene-styrene terpolymer Parts; tetrakis-[β-(3.2-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester (antioxidant 1010) 1 part; halogen-free high-gloss black pigment 2 parts. Mix ASA, PMMA, maleic anhydride, 2,4-dichlorobenzoyl peroxide and methyl methacrylate-butadiene-styrene terpolymer for 3 minutes until the appearance is uniform; add di Cumene, Antioxidant 1010, Antioxidant 168 and Halogen-free high-gloss black pigment, mixed until the appearance is uniform;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com