A preparation method of wood-plastic floor tiles for garden walkways

A walkway and wood-plastic technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of weakened bonding force between floor tiles and the ground, high maintenance cost, and easy loosening of the mortar layer, etc., to improve Anti-slip properties, extended life, increased gloss and protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing wood-plastic floor tiles for garden walkways, comprising the preparation of wood-plastic floor tile base materials, the preparation of main brick bodies and the preparation of auxiliary brick bodies, including the following steps:

[0031] Step 1. Preparation of base material for wood-plastic floor tiles: Take the formula components of wood-plastic floor tiles, put them into a high-speed mixer and mix them evenly. Melt to get liquid wood-plastic base material, set aside;

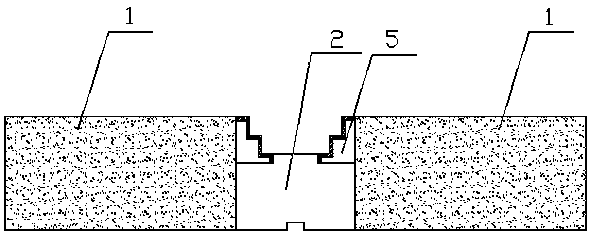

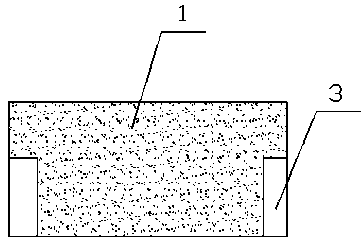

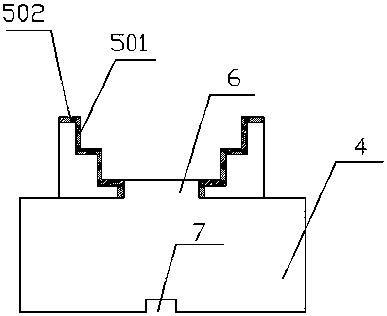

[0032] Step 2. Preparation of the main brick body 1: a. Take part of the liquid wood-plastic base material in step 1 and put it into the forming mold, press and set it for 22-30 minutes, take it out after cooling and molding, and obtain the main brick body 1, the main brick body 1 is a cuboid, and the lower part of both sides of the main brick body 1 is provided with a rectangular groove 3 whose height is one-fifth to one-fourth of the height of the main brick body 1;

[0033] ...

Embodiment 1

[0043] A method for preparing wood-plastic floor tiles for garden walkways, comprising the preparation of wood-plastic floor tile base materials, the preparation of main brick bodies and the preparation of auxiliary brick bodies, including the following steps:

[0044] Step 1. Preparation of base material for wood-plastic floor tiles: Take the formula components of wood-plastic floor tiles sold on the market, put them into a high-speed mixer and mix them evenly. Melt to get liquid wood-plastic base material, set aside;

[0045] Step 2. Preparation of the main brick body 1: a. Take part of the liquid wood-plastic base material in step 1 and put it into a molding mold, press and shape it for 22 minutes, take it out after cooling and molding, and obtain the main brick body 1, and the main brick body 1 is Cuboid, the lower part of both sides of the main brick body 1 is provided with a rectangular groove 3 with a height of one-fifth to one-fourth of the height of the main brick bod...

Embodiment 2

[0050] A method for preparing wood-plastic floor tiles for garden walkways, comprising the preparation of wood-plastic floor tile base materials, the preparation of main brick bodies and the preparation of auxiliary brick bodies, including the following steps:

[0051] Step 1. Preparation of base material for wood-plastic floor tiles: Take the formula components of wood-plastic floor tiles sold on the market, put them into a high-speed mixer and mix them evenly. Melt to get liquid wood-plastic base material, set aside;

[0052] Step 2. Preparation of the main brick body 1: a. Take part of the liquid wood-plastic base material in step 1 and put it into a forming mold, press and set it for 26 minutes, take it out after cooling and molding, and obtain the main brick body 1, and the main brick body 1 is Cuboid, the lower part of both sides of the main brick body 1 is provided with a rectangular groove 3 with a height of one-fifth to one-fourth of the height of the main brick body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com